Fireproofing insulation board

A technology of fireproof insulation board and insulation board, which is applied in the direction of insulation, fire prevention, building components, etc., can solve the problems of flammability and hidden danger of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

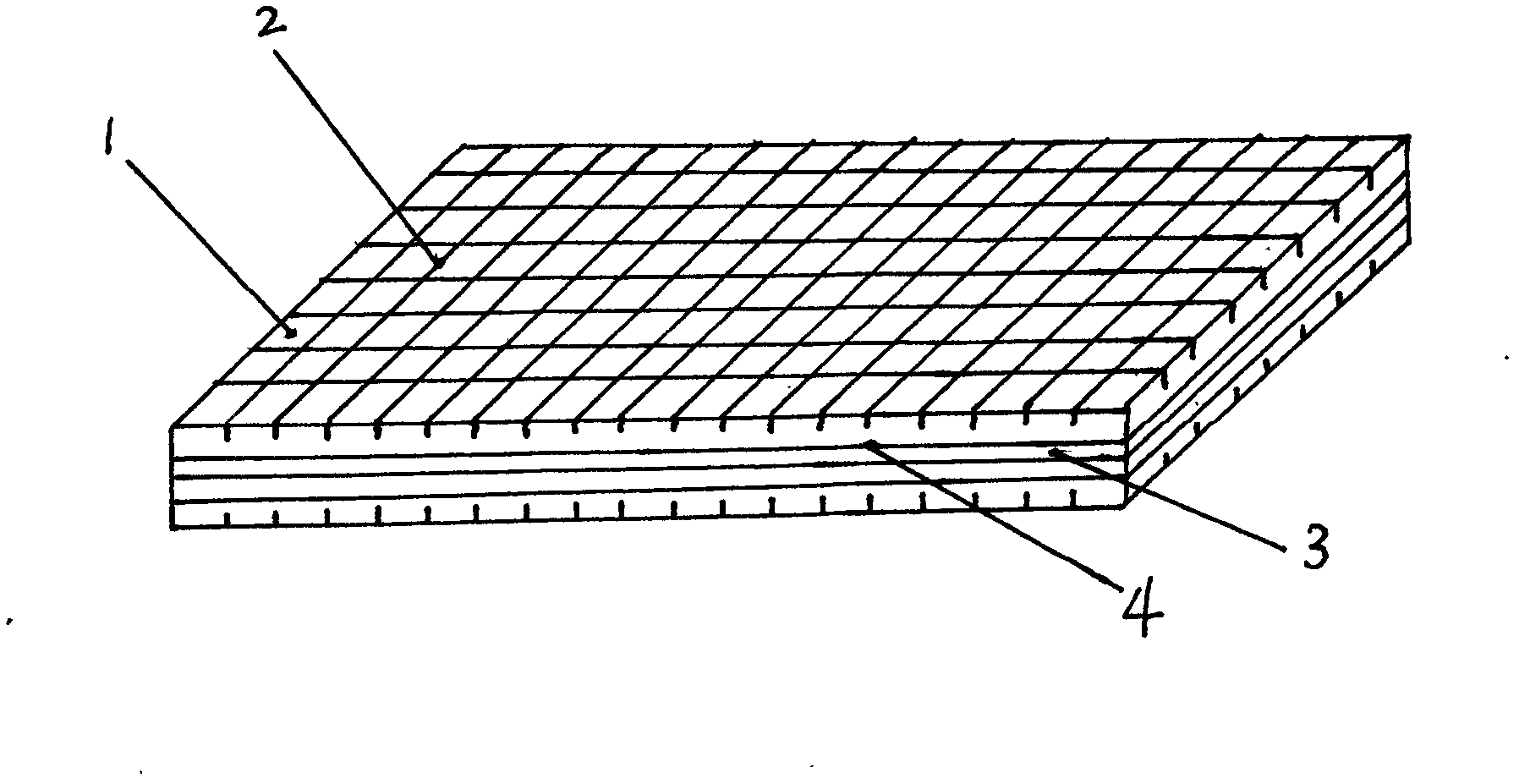

[0010] With reference to the accompanying drawings, it includes a polystyrene insulation board or a polyethylene insulation board 1; one or both sides of the polystyrene insulation board or polyethylene insulation board are provided with several groove lines parallel to each other, or several criss-cross groove lines are established, A flame retardant screen 2 is arranged in the groove line, and the flame retardant screen can be made of polymer cement mortar or interface treatment flame retardant or polymer cement.

[0011] The distance between adjacent groove lines can be 20mm, 30mm, 40mm or 50mm.

[0012] The vertical distance between the bottom of the groove line on one side and the other side of the polystyrene insulation board or polyethylene insulation board is preferably 7mm-10mm. If groove lines are arranged on both sides, the vertical distance between the bottom of the groove line on one side and the bottom of the groove line on the other side should also be 7mm-10mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com