Extra-high-pressure wall bushing

A through-wall bushing, UHV technology, applied in electrical components, substation/switch layout details, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

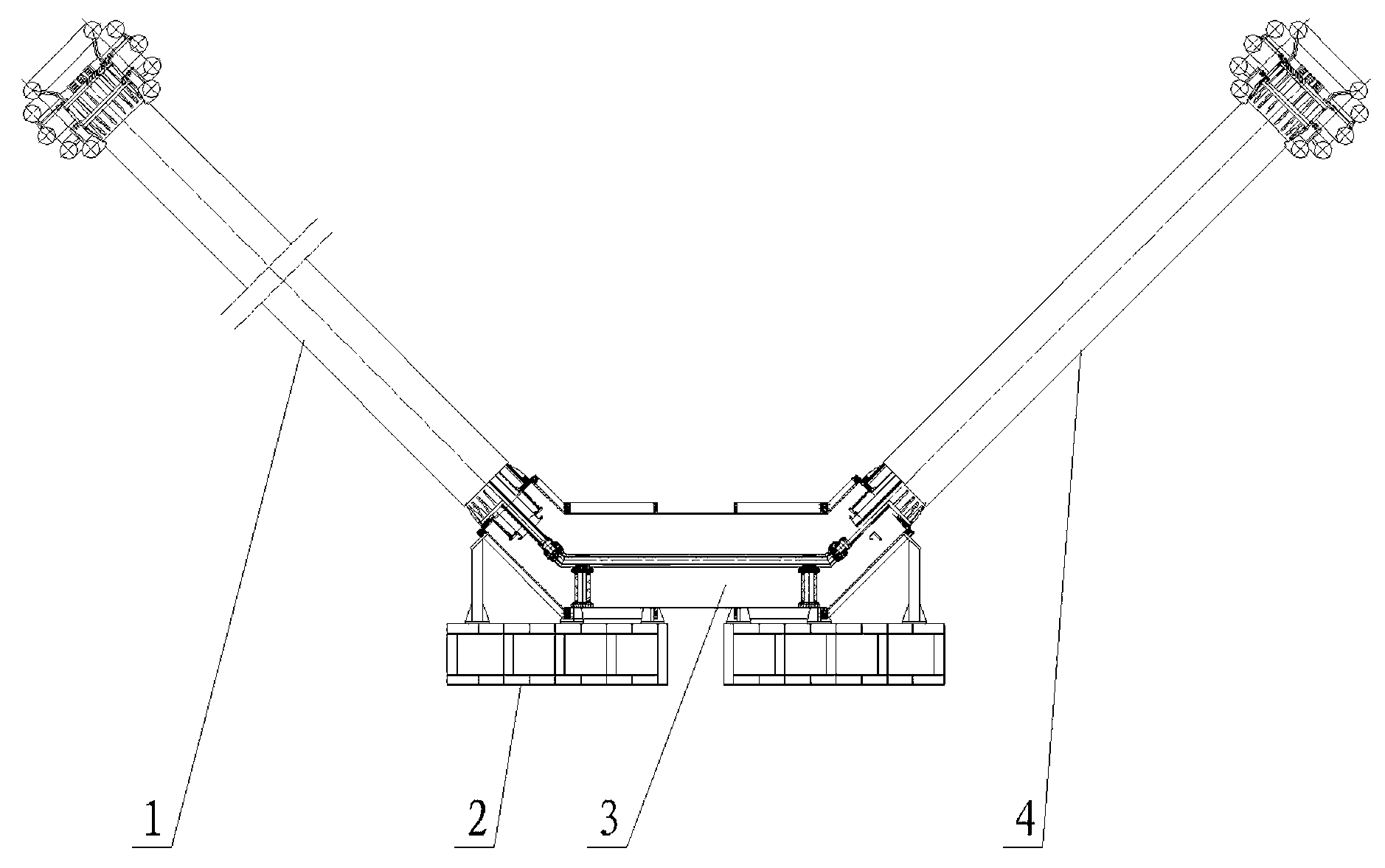

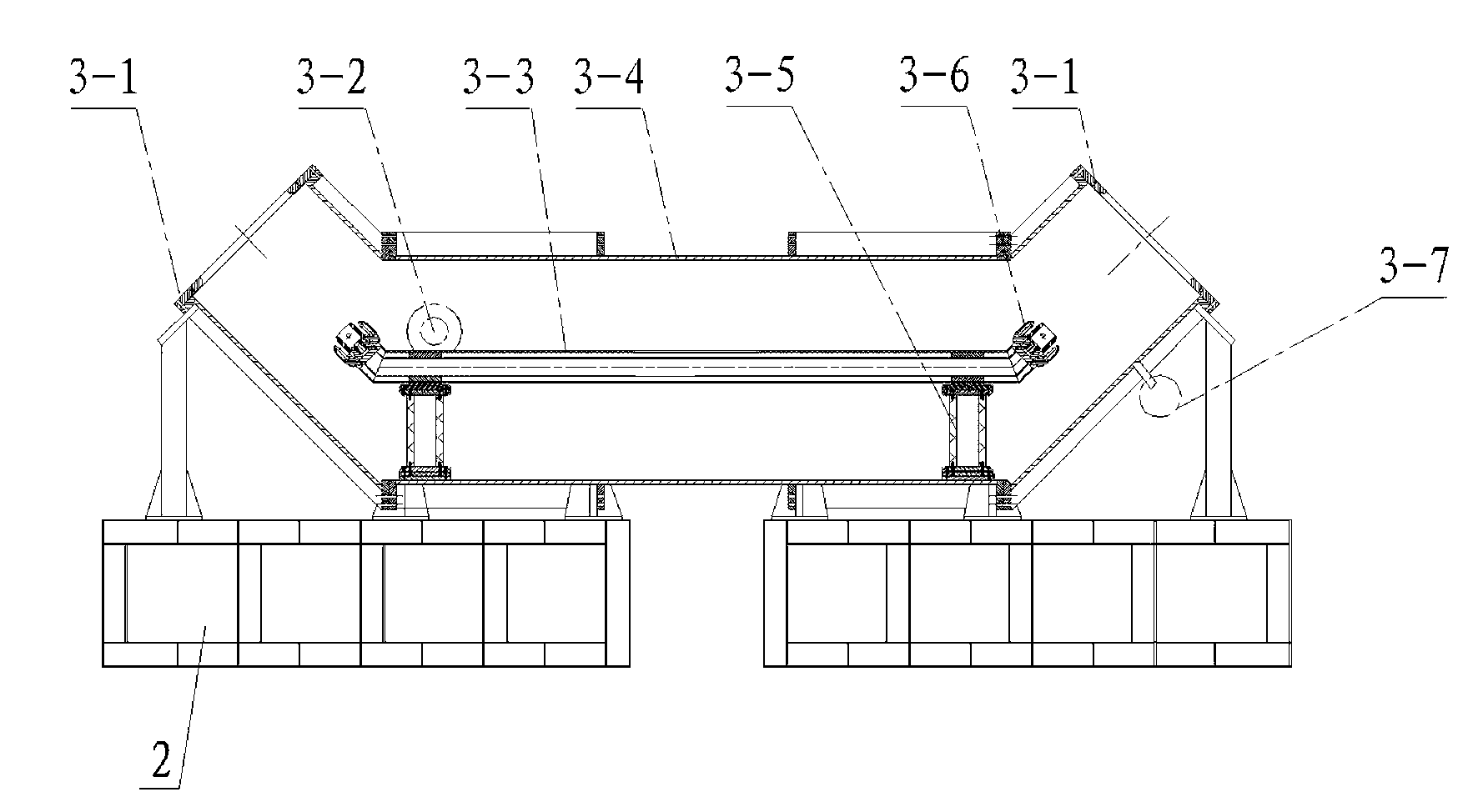

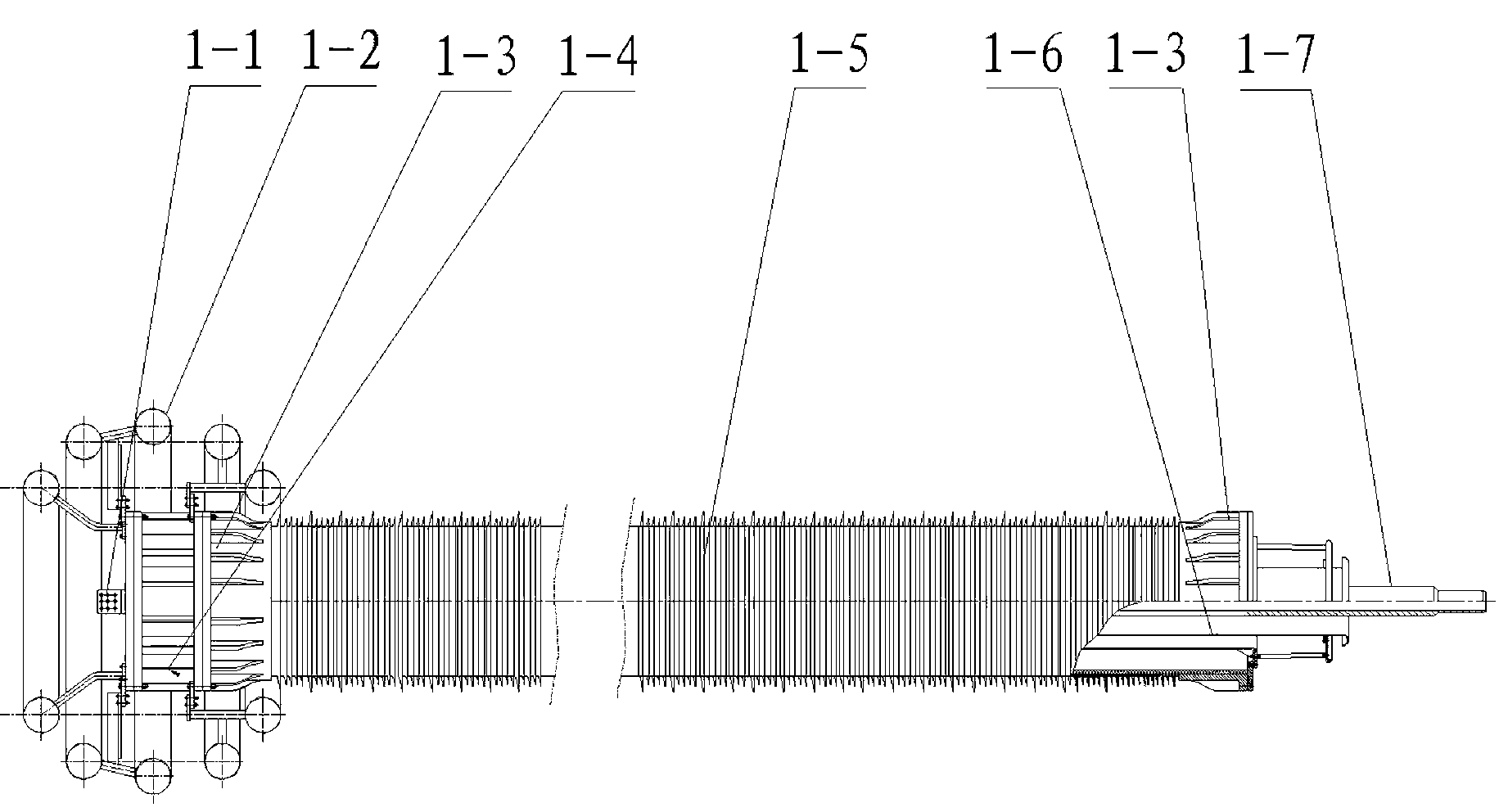

[0023] like figure 1 The UHV wall-piercing bushing shown in the figure includes an outdoor bushing 1, an intermediate connecting pipe 3 and an indoor bushing 4 connected in sequence. The outdoor bushing 1 and the indoor bushing 4 are straight pipes, and the outdoor bushing 1 The lower end of the lower end of the casing 4 and the lower end of the indoor casing 4 are respectively connected to the two ends of the intermediate connecting pipe 3, and the outdoor casing 1 and the indoor casing 4 are respectively inclined towards the two outer sides of the intermediate connecting pipe 3, so that the overall shape forms a V-like shape. font, the intermediate connecting pipe 3 is connected with a ground support.

[0024] The middle straight ends of the intermediate connecting pipe 3 are tilted upwards, and the angles between the two ends of the intermediate connecting pipe 3 and the middle part are 120-150 degrees. Part of the angle is 120-150 degrees.

[0025] like figure 2 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com