Rubber composition and method of producing same, and tire

一种橡胶组合物、制造方法的技术,应用在特殊轮胎、轮胎零部件、运输和包装等方向,能够解决组合物加工性恶化等问题,达到优异耐断裂性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 6 and comparative example 1 to 2

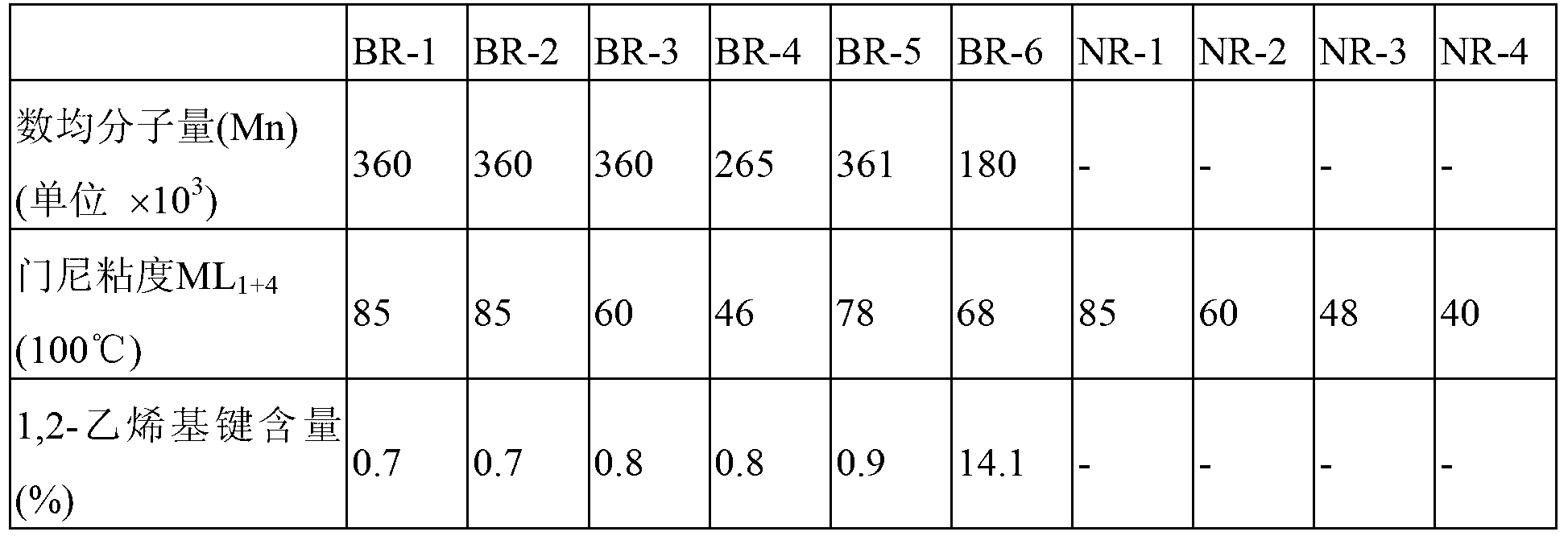

[0169] A mixture having the composition formulation shown in Table 3 below was kneaded with a Banbury mixer to obtain an unvulcanized rubber composition, which was then sheeted to have a thickness of 2 mm and vulcanized at 145° C. for 30 minutes. The rubber properties of the obtained vulcanized rubber were evaluated according to the above-mentioned method.

[0170] From the formulations of Examples and Comparative Examples shown in Table 3, carbon black was removed; the remaining formulations were individually kneaded and vulcanized in the same manner as above. The abrasion resistance and fracture resistance of the obtained sheet were evaluated. Processability was evaluated in the kneading stage. The results are summarized and shown in Table 3.

[0171] [table 3]

[0172]

[0173] [Note]

[0174] 1) Carbon black: ISAF, trade name "Asahi#80" of Asahi Carbon

[0175] 2) Antiaging agent 6C: N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine, Seiko Chemical's trade name "O...

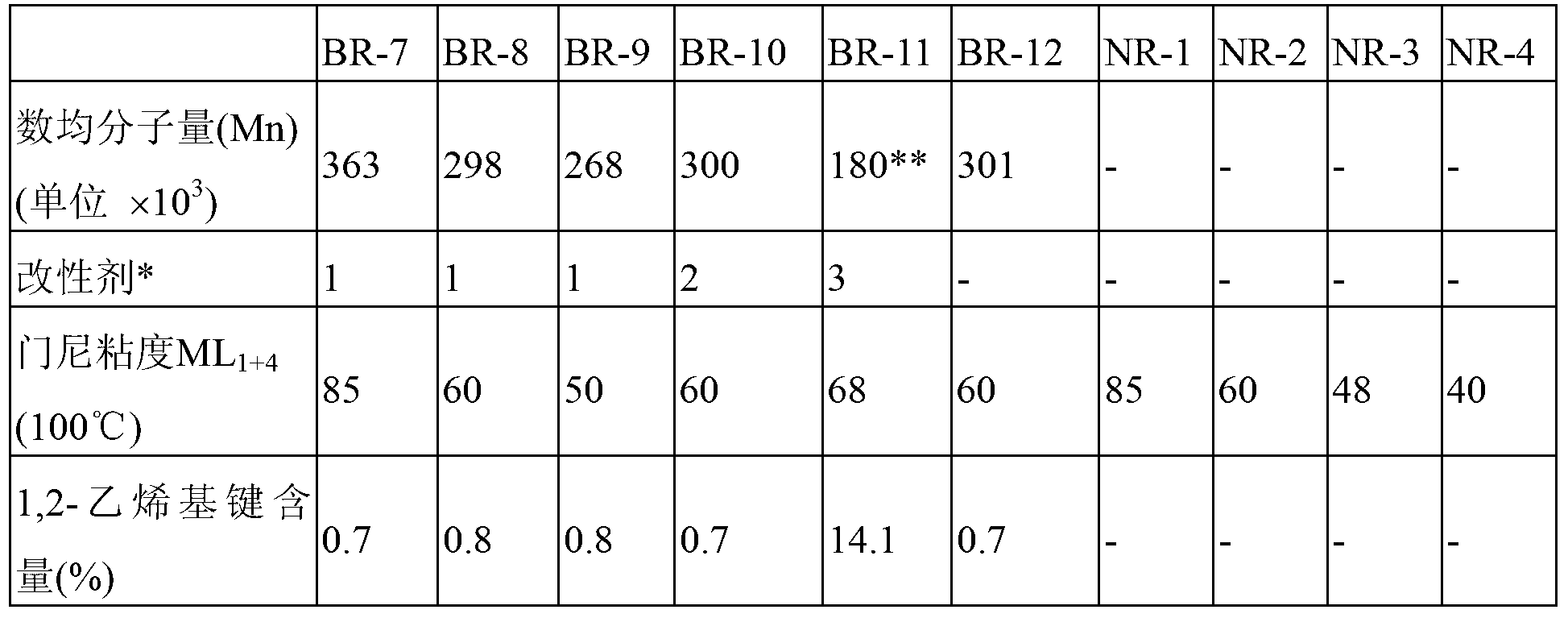

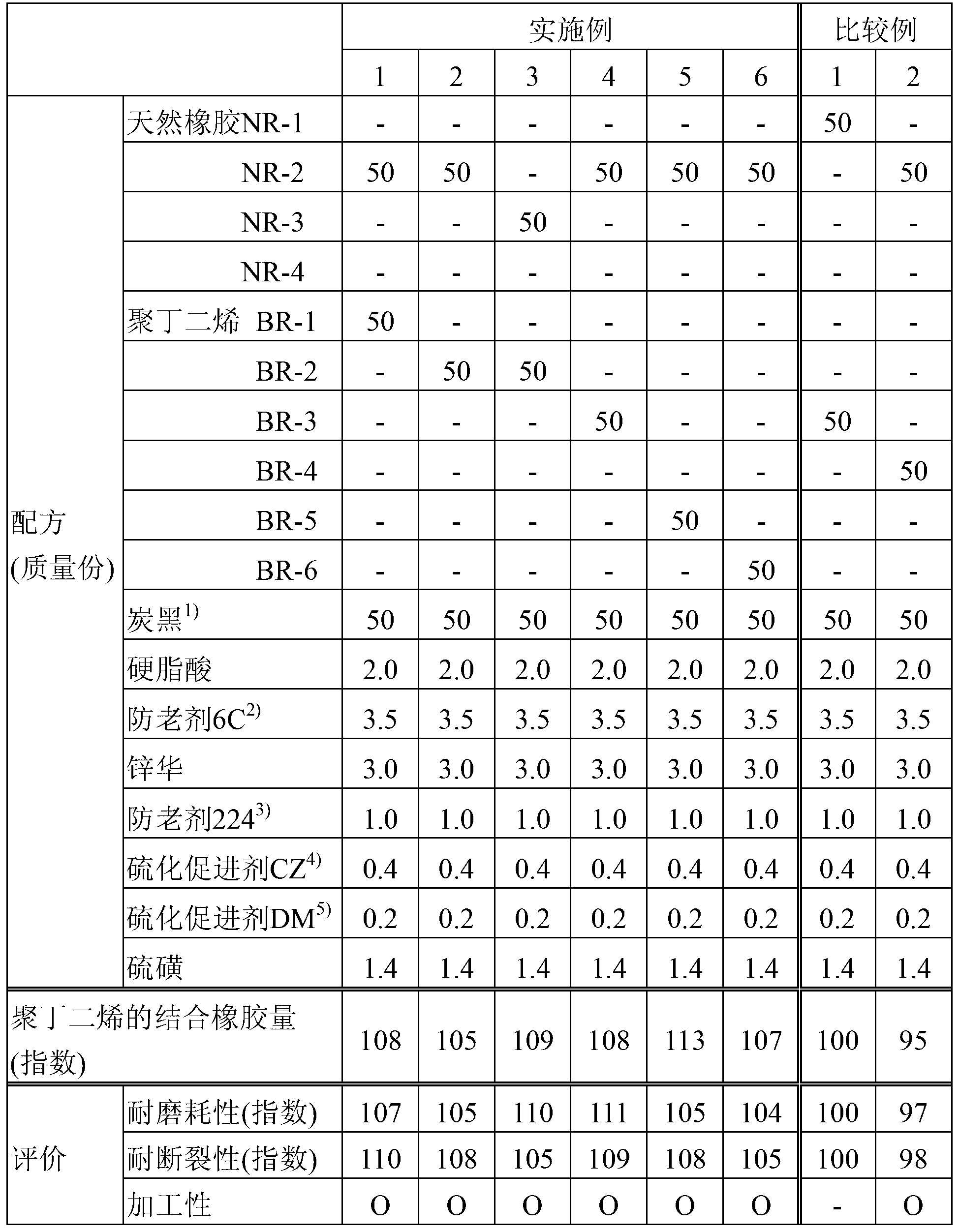

Embodiment 7 to 12 and comparative example 3

[0180]A mixture having the composition formulation shown in Table 4 below was kneaded with a Banbury mixer to obtain an unvulcanized rubber composition, which was then sheeted to have a thickness of 2 mm and vulcanized at 145° C. for 30 minutes. The rubber properties of the obtained vulcanized rubber were evaluated according to the above-mentioned method.

[0181] From the formulations of Examples and Comparative Examples shown in Table 4, carbon black was removed; the remaining formulations were individually kneaded and vulcanized in the same manner as above. The abrasion resistance, fracture resistance and low loss property of the obtained sheet were evaluated. The results are summarized and shown in Table 4.

[0182] [Table 4]

[0183]

PUM

| Property | Measurement | Unit |

|---|---|---|

| rate of recovery | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com