Radiating element for irradiating surfaces, having a socket

A radiator and irradiation technology, applied in the field of radiators, can solve the problems of inability to install and equipment consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

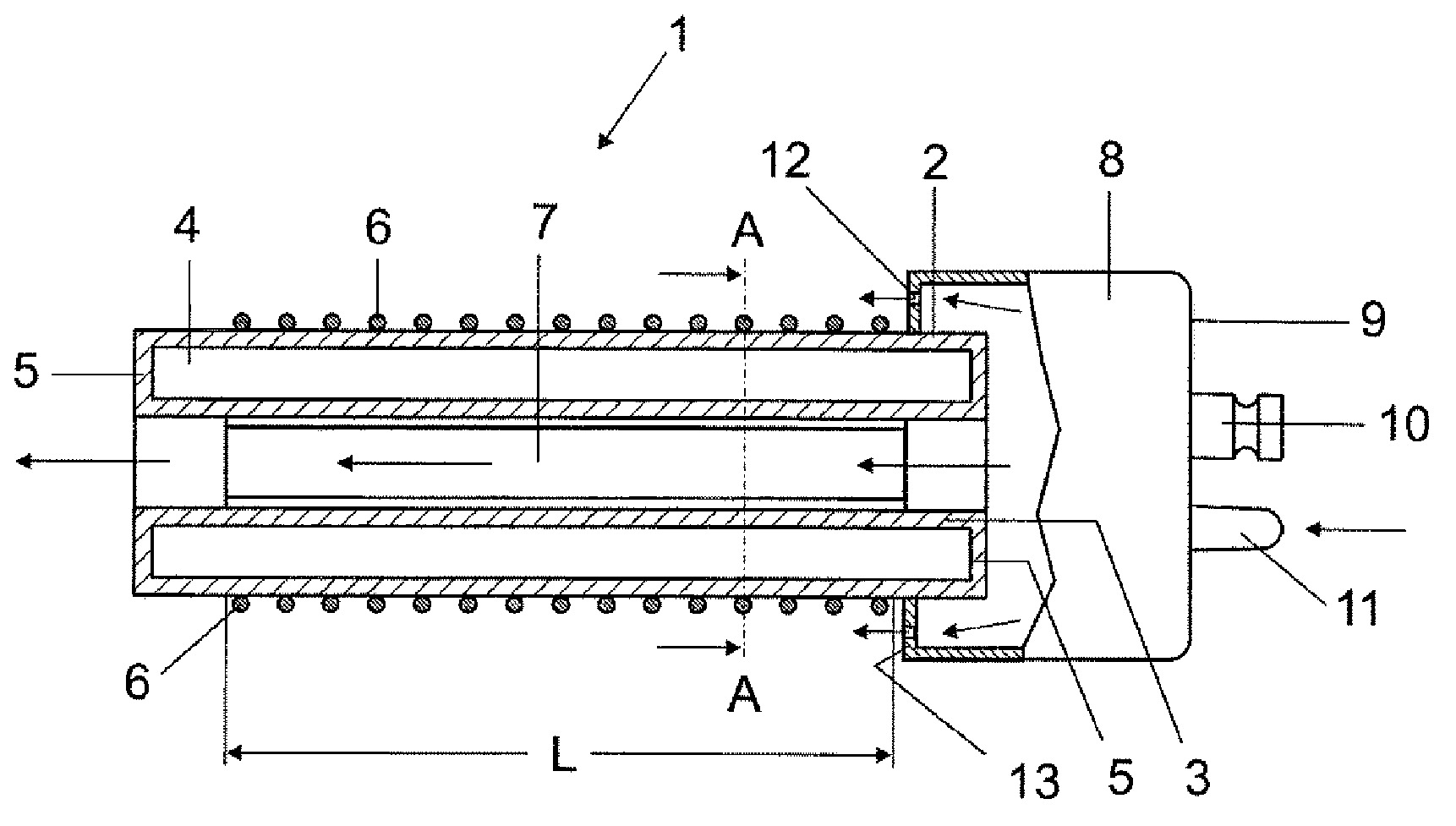

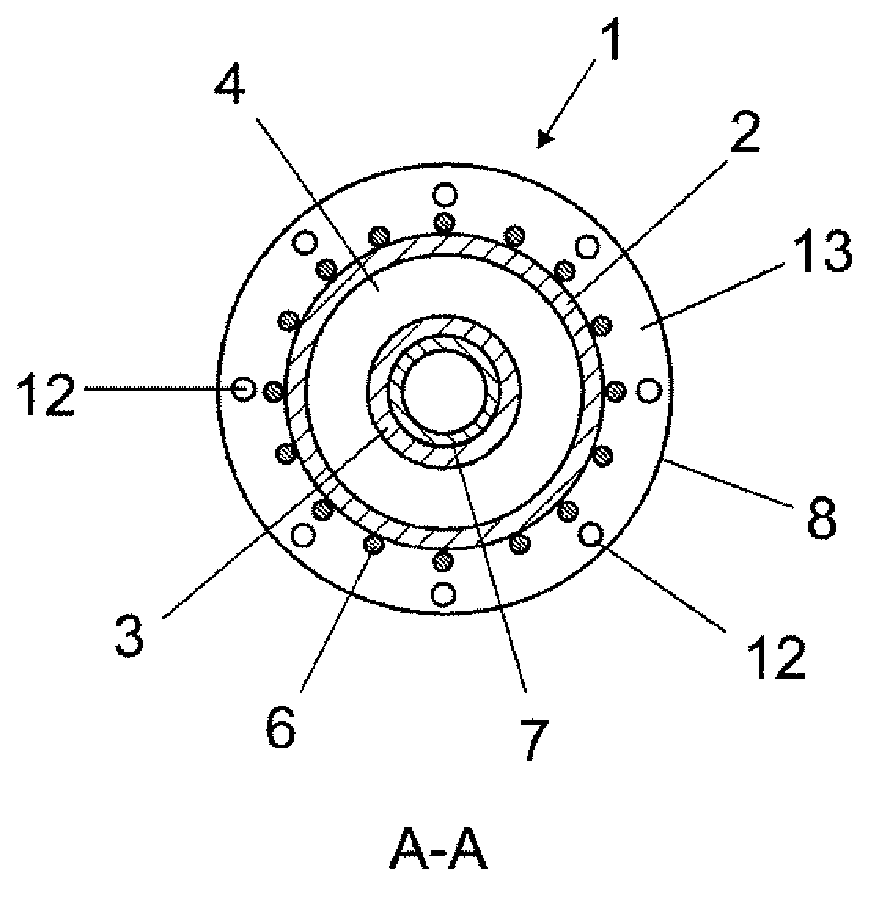

[0026] Figure 1a , 1bA partially broken longitudinal view and a cross-sectional view of a first exemplary embodiment of a radiator 1 according to the invention based on a dielectric barrier discharge are shown in a very schematic illustration. The elongated discharge vessel of the radiator 1 consists of an outer tube 2 and an inner tube 3 in a coaxial twin-tube construction, which thus define the longitudinal axis of the discharge vessel. The length of the tube varies according to the application. In order to sterilize the bottle, for example, the length is advantageously determined such that the inside of the bottle is completely irradiated when the radiator sinks in. The diameter of the tube is likewise advantageously adapted to the application. In particular, the largest outer diameter of the discharge vessel is dimensioned such that the radiator 1 can be inserted, for example, into a container provided for irradiation, for example into a bottle through the neck of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com