Self-locking bracket

A self-locking, bracket technology, applied in the field of orthodontics, can solve the problems of difficult manufacturing, difficult operation, high price, etc., and achieve the effects of simple production, no cumbersome operation, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

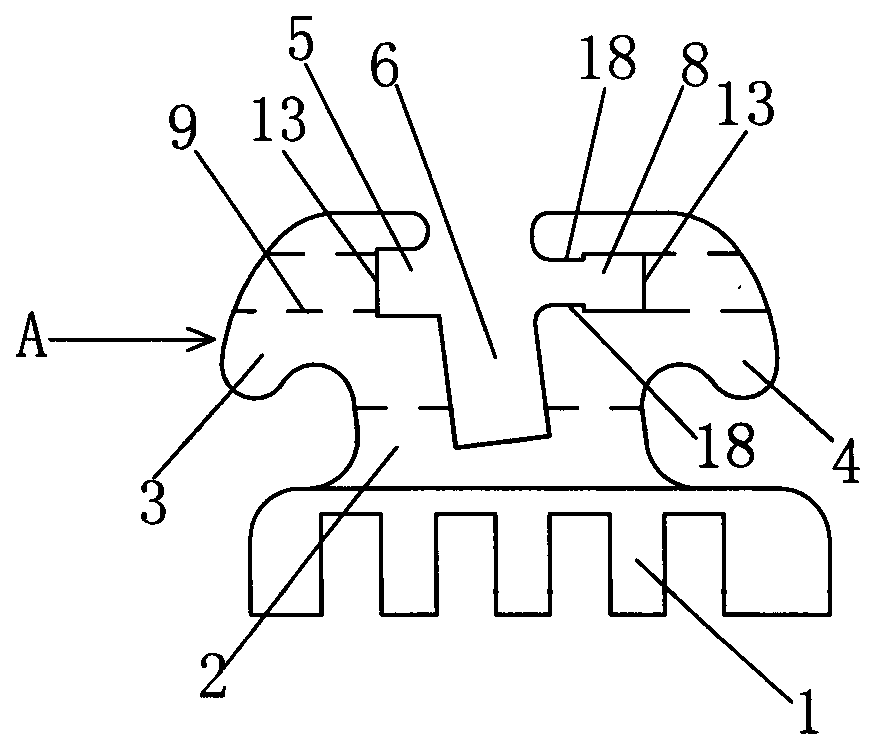

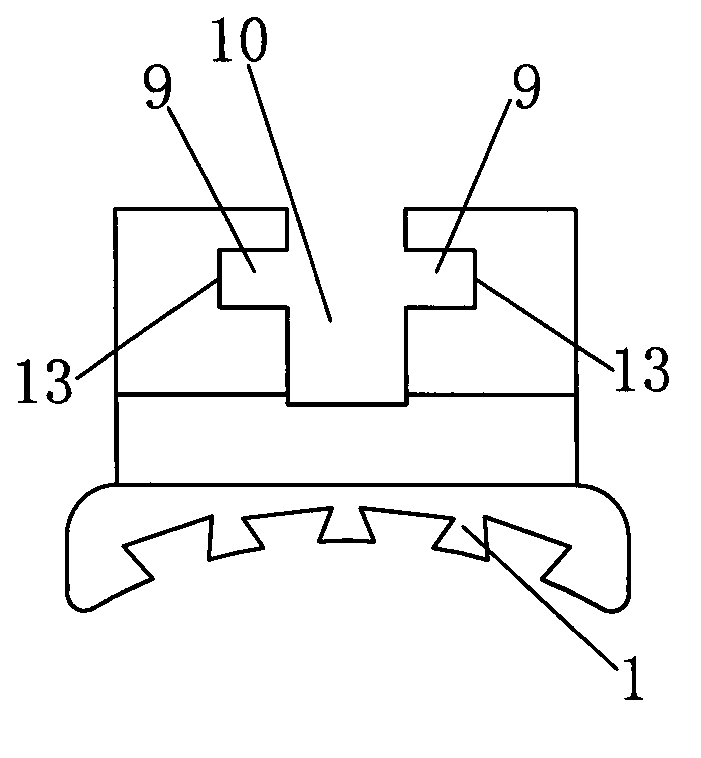

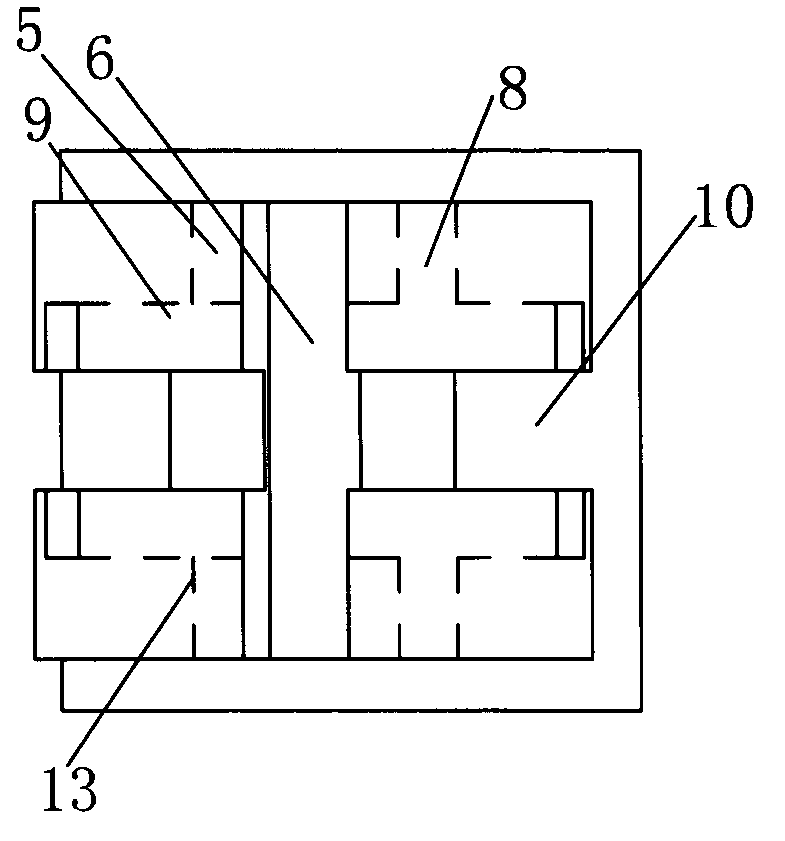

[0022] Embodiment: a kind of self-locking bracket, as Figure 1~3 As shown, it includes a bracket body 2 with a mesh bottom 1 and an archwire groove 6. The two sides of the archwire groove 6 are provided with working wings 3 and 4, and the bracket body 2 intersects the archwire groove 6 with The bracket opening 10, the bracket opening 10 and the archwire groove 6 are intersected, and the bracket opening 10 and the archwire groove 6 divide the working wings 3 and 4 into four separate pieces, as figure 1 , figure 2 As shown, the two sides of the bracket opening 10 are symmetrically provided with the chute 9 formed by wire cutting, and the chute 9 is vertically provided with a groove edge 13 .

[0023] like Image 6 , Figure 7 As shown, a bracket cover 11 is slid in the chute 9, as Figure 4 , Figure 5 As shown, the two sides of the bracket cover 11 are provided with slide bars 15 that cooperate with the chute 9, a gap 50 is provided between the two slide bars 15 at the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com