Instrument for extraction

An instrument and extraction technology, used in chemical instruments and methods, laboratory containers, liquid solution solvent extraction, etc. The effect of human body damage and environmental pollution, prevention of bottle explosion, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

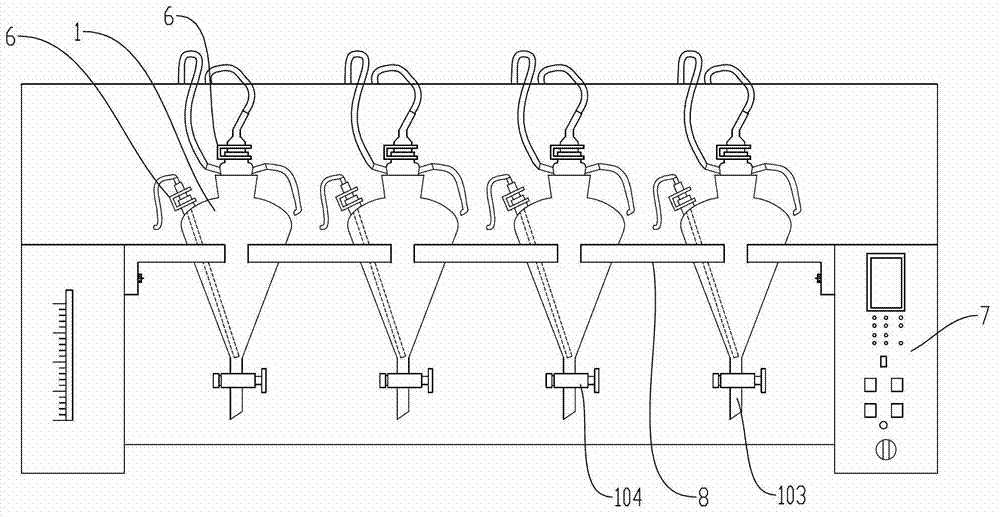

[0029] Such as figure 1 As shown, the extraction apparatus mainly includes a separatory funnel 1, an air pump 2, a cleaning liquid supply device 3, a cleaning liquid supply device 4, and an electric control device 5.

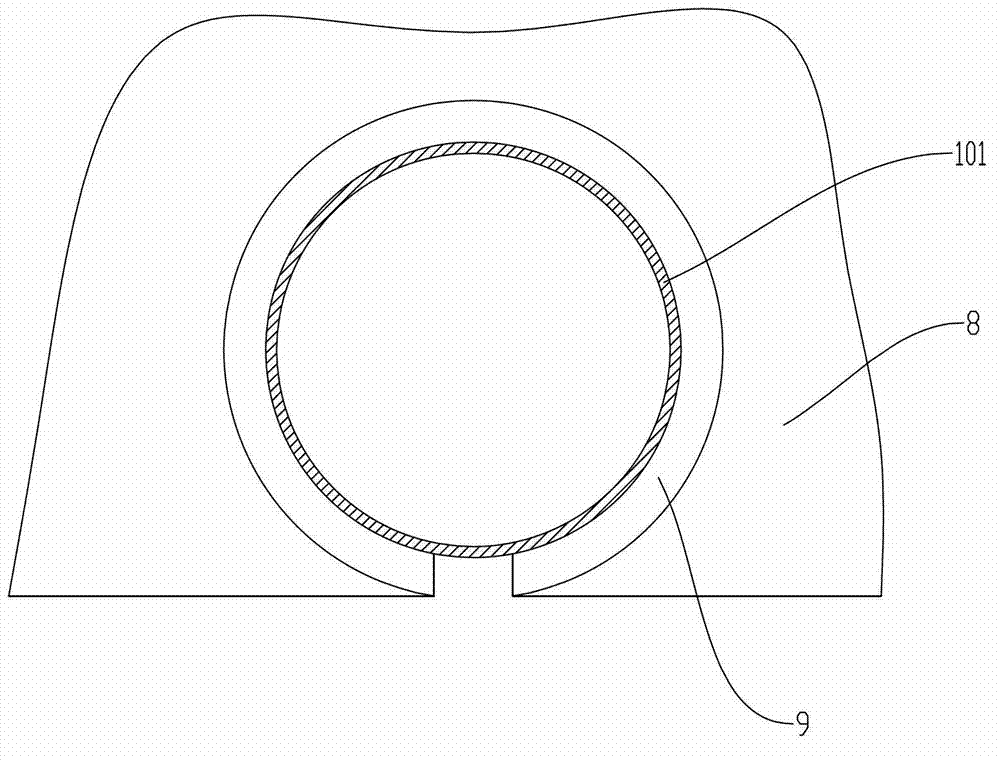

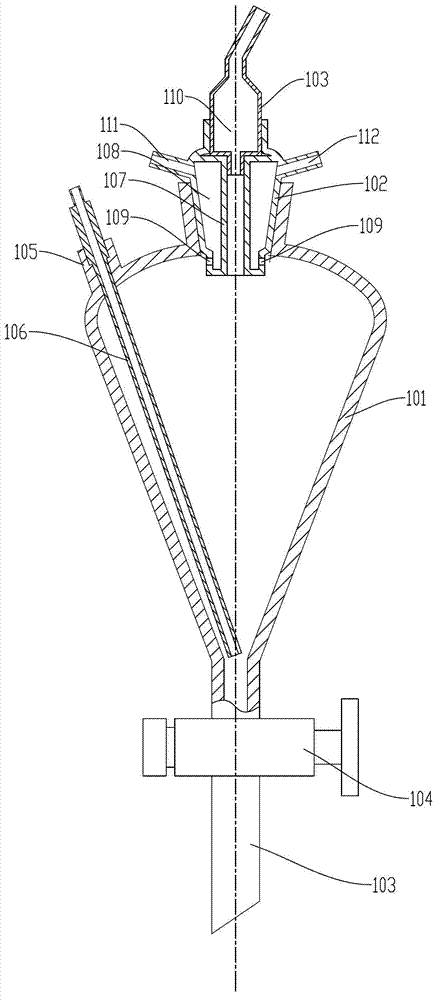

[0030] Such as image 3 As shown, the separating funnel 1 includes a funnel body 101 and a bottle stopper assembly. A liquid outlet pipe 103 is provided at the bottom of the bucket body 101 , and a liquid outlet valve 104 is provided on the liquid outlet pipe 103 .

[0031] The top of the separatory funnel 1 is provided with an air inlet, and the air inlet includes a through hole arranged on the bucket body 101 , and a cylindrical portion 105 extends from the through hole to the outside of the bucket body. Described air inlet is communicated with air inlet pipe 106, and this air inlet pipe 106 is positioned at the bucket body 101 of separatory funnel, and the bottom end of air inlet pipe 106 is positioned at the inner bottom of bucket body 101 and is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com