Fitting method between touch screen module and liquid crystal display module

A liquid crystal screen and touch screen technology, which is applied in the field of lamination of touch screen modules and liquid crystal screen modules, can solve the problems of Newton rings, yield drop, inconvenient maintenance, etc., and achieves simple operation procedures, high qualification rate, and convenient replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to understand the essence of the present invention more clearly and intuitively.

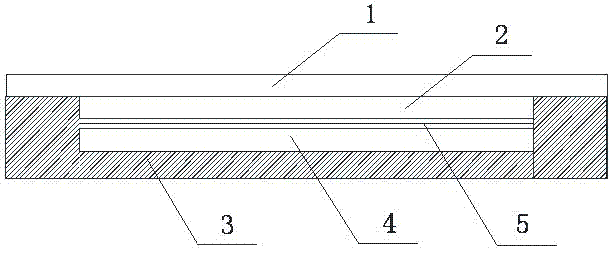

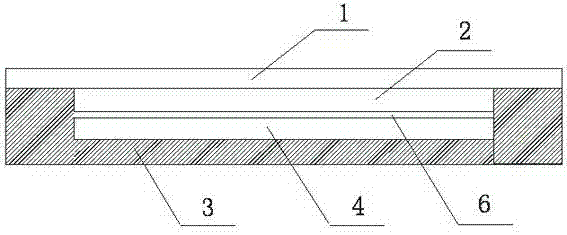

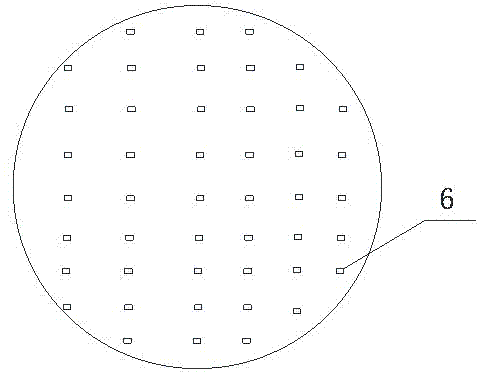

[0016] Such as figure 1 As shown, the touch screen module includes a cover plate 1 and a touch sensor 2 attached to the bottom of the cover plate 1, and a layer of fog film 5 is pasted on the bonding surface of the touch sensor 2 and the liquid crystal screen module 4 or the surface of the liquid crystal screen module 4 , the casing 3 of the electronic equipment is arranged on the lower surface of the liquid crystal screen module 4 and is attached to the cover plate 1 at both ends with double-sided adhesive tape. The surface of the matte film 5 is a micro-grain frosted surface, and this micro-particle frosted surface produces a supporting effect in the gap after the touch screen module and the liquid crystal screen module are bonde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com