Upper bracket of tower crane and tower crane

A tower crane and boom technology, applied in cranes and other directions, can solve the problems of large size, stress concentration, and difficult processing, and achieve the effects of reducing production costs, reducing strength requirements, and alleviating stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

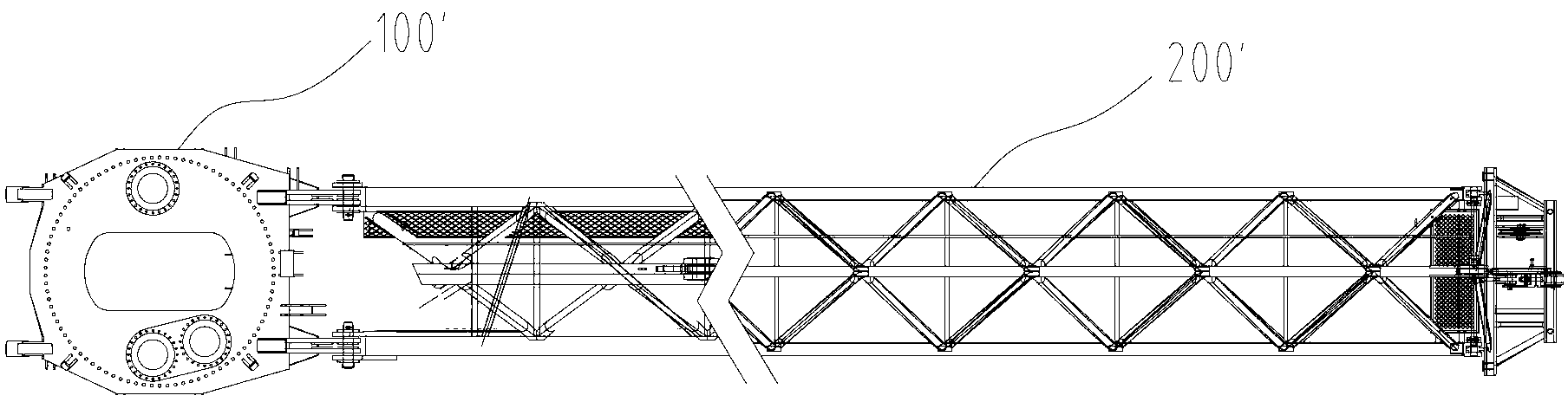

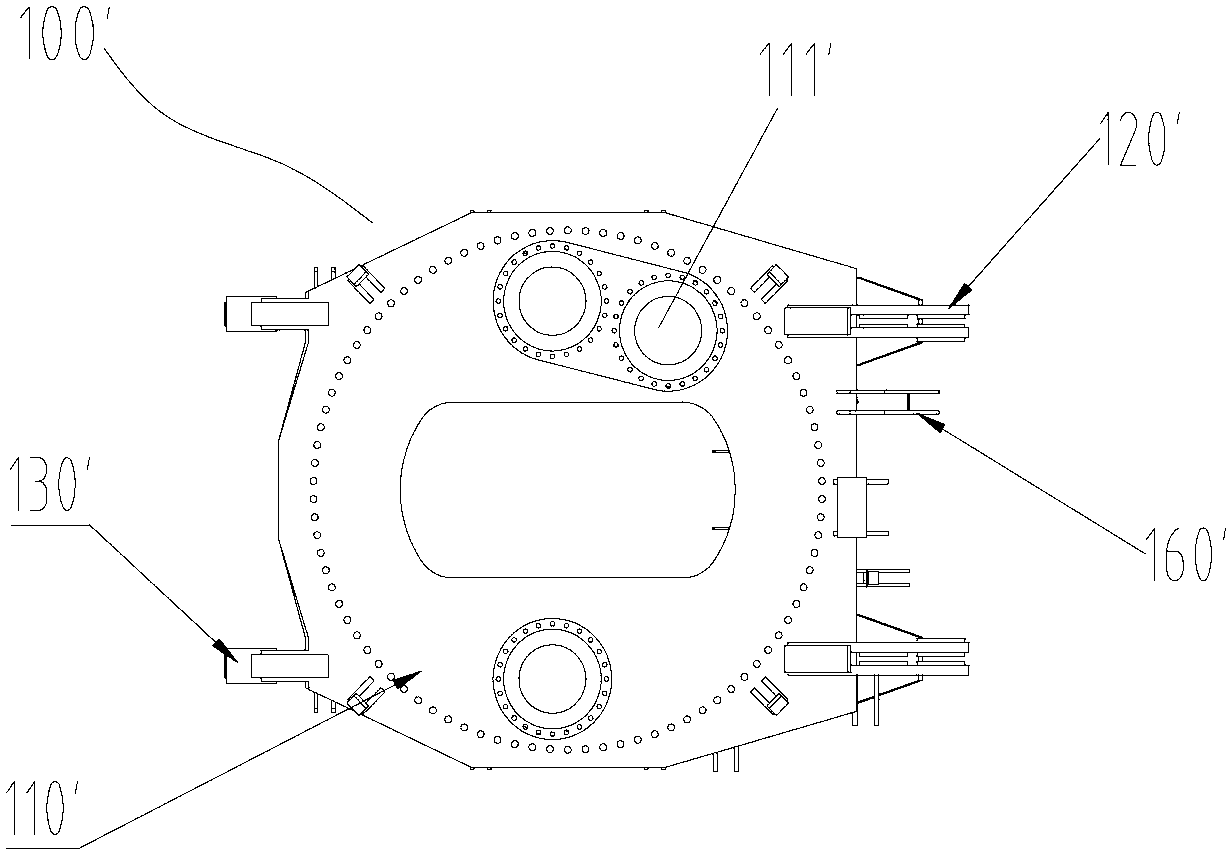

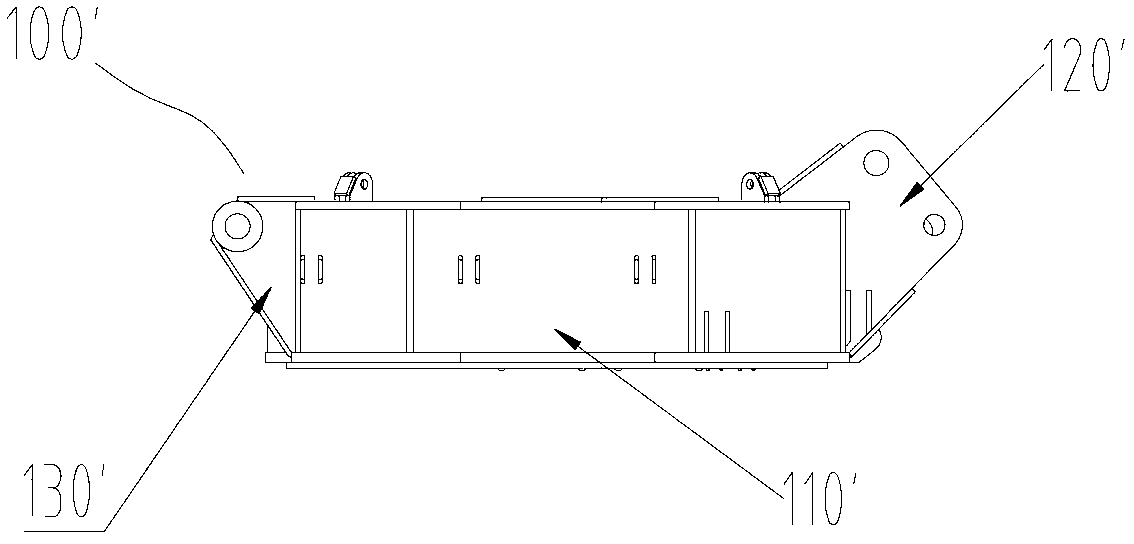

[0039] Such as Figure 5 and Image 6As shown, the tower crane of the present invention includes an upper support 100 and a lifting arm 200 and a balance arm 300 respectively supported on the upper support 100 . The boom 200 includes a first boom 210 and a second boom 220 that are independent from each other and arranged in parallel. The tower crane of the present invention breaks the traditional single jib form, and the jib 200 of the tower crane is set to include a first jib 210 and a second jib 220 that are independent of each other and arranged side by side, which can solve the problem of existing Large or super large tower cranes consume too much energy when hoisting light loads during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com