Method for preparing tungsten molybdenum copper composite material

A composite material, tungsten-molybdenum technology, applied in the field of preparation of tungsten-molybdenum-copper composite materials, can solve the problems of immature production and application, difficulty in completely discharging pores, and difficulty in densification of sintered bodies, so as to achieve high density, eliminate carbonization, The effect of reducing the mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

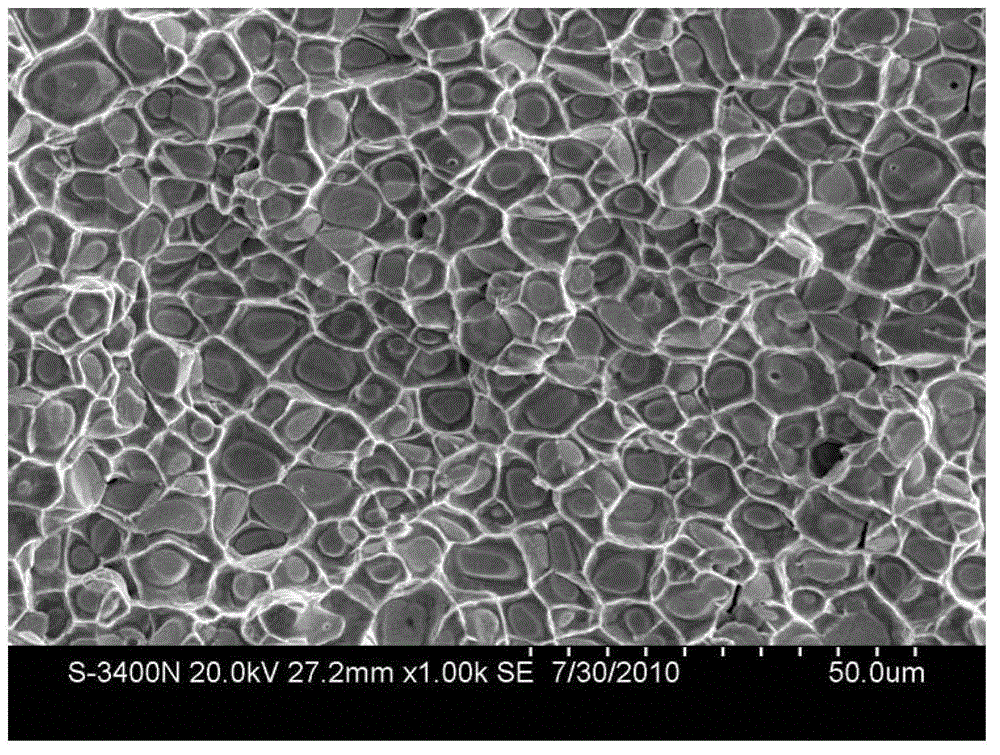

[0031] Preparation of W60Mo20Cu20 Composite Material

[0032] Step 1. Sieve the tungsten powder with a Fisher’s particle size of 1.0 μm and the molybdenum powder with a Fisher’s particle size of 3.5 μm, respectively, using a 200 mesh / 300 mesh / 400 mesh multi-stage sieve to obtain tungsten with a Fisher’s particle size of 1.5 μm. powder and molybdenum powder with a Fischer particle size of 3 μm, then add 6 kg of tungsten powder with a Fischer particle size of 1.5 μm and 2 kg of molybdenum powder with a Fischer particle size of 3 μm into a molybdenum ball mill tank, and use 8 kgФ5 molybdenum balls to mix for 60 minutes Finally, the mixed powder of tungsten and molybdenum is obtained;

[0033] Step 2. Weigh 1100g of the tungsten-molybdenum mixed powder described in step 1, put it into a mold cavity with a length and width of 50mm and 100mm respectively, and use a hydraulic press to limit the pressure to a height of 20mm to obtain a porosity of 35%. 20×50×100mm tungsten and molybd...

Embodiment 2

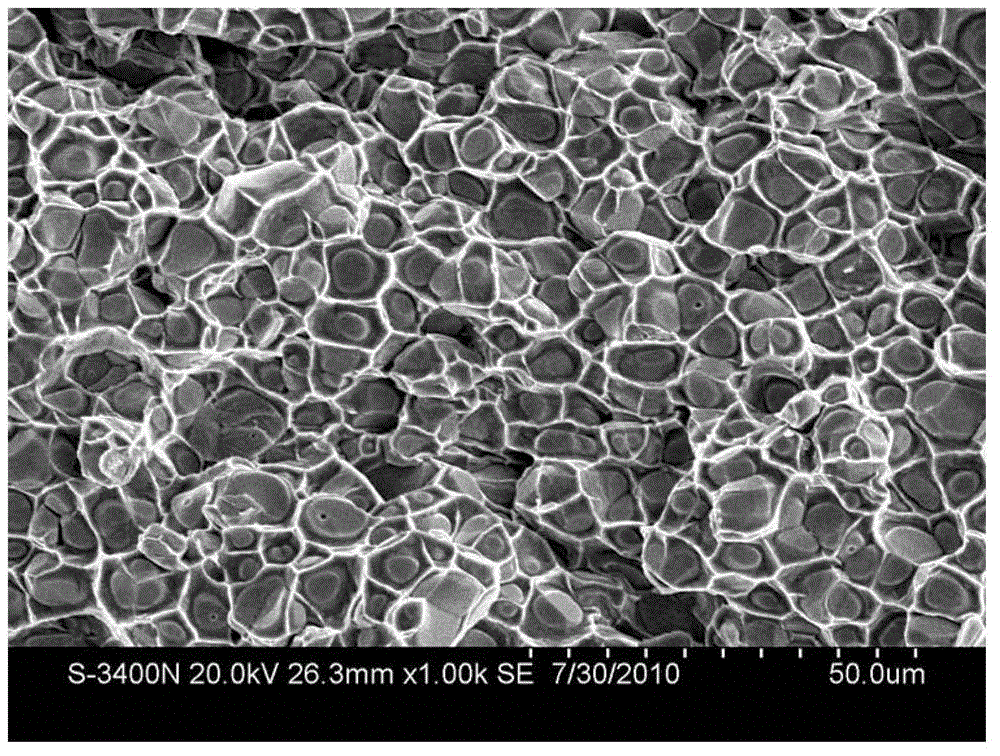

[0039] Preparation of W30Mo40Cu30 Composite Material

[0040] Step 1. Sieve the tungsten powder with a Fisher’s particle size of 1.0 μm and the molybdenum powder with a Fisher’s particle size of 3.5 μm, respectively, using a 200 mesh / 300 mesh / 400 mesh multi-stage sieve to obtain tungsten with a Fisher’s particle size of 1.5 μm. powder and molybdenum powder with a Fischer particle size of 3 μm, then add 3 kg of tungsten powder with a Fischer particle size of 1.5 μm and 4 kg of molybdenum powder with a Fischer particle size of 3 μm into a molybdenum ball mill tank, and use 7 kgФ5 molybdenum balls to mix for 120 minutes Finally, the mixed powder of tungsten and molybdenum is obtained;

[0041] Step 2. Weigh 1250g of the tungsten-molybdenum mixed powder described in step 1, put it into a mold cavity with a length and a width of 50mm and 100mm respectively, and use a hydraulic press to limit the pressure to a height of 30mm to obtain a porosity of 41%. 30×50×100mm tungsten-molybde...

Embodiment 3

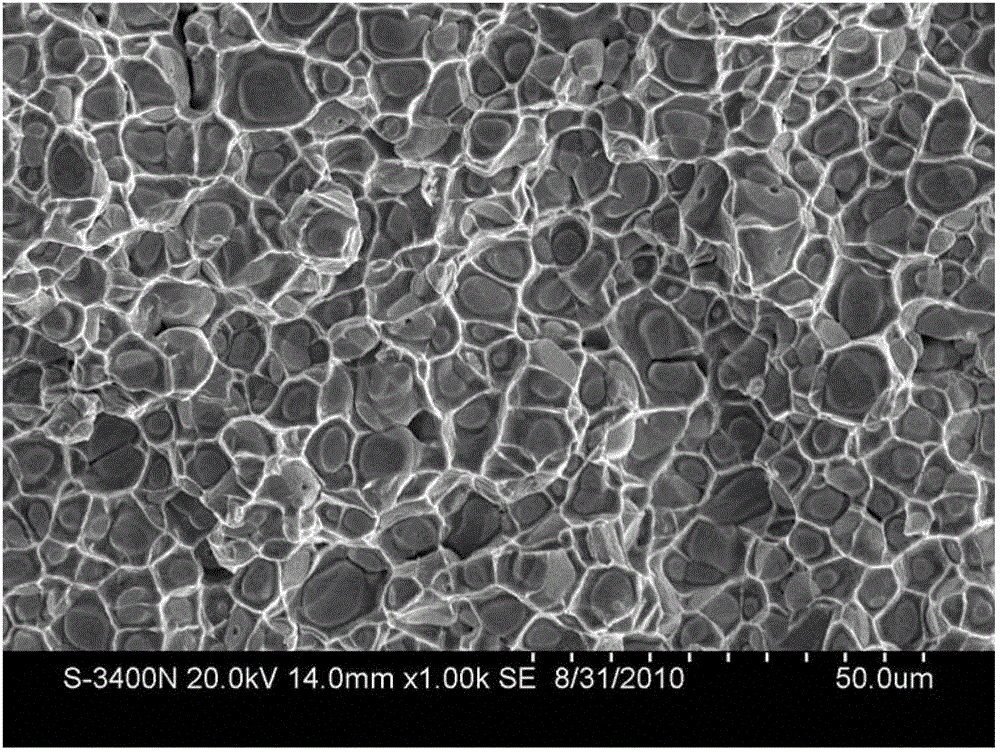

[0047] Preparation of W10Mo50Cu40 Composite Material

[0048] Step 1. Sieve the tungsten powder with a Fisher’s particle size of 1.0 μm and the molybdenum powder with a Fisher’s particle size of 3.5 μm, respectively, using a 200 mesh / 300 mesh / 400 mesh multi-stage sieve to obtain tungsten with a Fisher’s particle size of 1.5 μm. powder and molybdenum powder with a Fischer particle size of 3 μm, then add 1.2 kg of tungsten powder with a Fischer particle size of 1.5 μm and 6 kg of molybdenum powder with a Fischer particle size of 3 μm into the molybdenum ball mill tank, and use 7.2 kgФ5 molybdenum balls for ball milling After mixing for 240 minutes, tungsten-molybdenum mixed powder was obtained;

[0049] Step 2. Weigh 1250g of the tungsten-molybdenum mixed powder described in step 1, put it into a mold cavity with a length and width of 50mm and 100mm respectively, and use a hydraulic press to limit the pressure to a height of 40mm to obtain a porosity of 45%. 40×50×100mm tungste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com