Emulsion explosive conveying twin-screw pump system

A technology of twin-screw pumps and emulsion explosives, applied in pumps, pump components, rotary piston pumps, etc., can solve problems such as wear of rubber stators, affecting the quality of emulsion explosives, and insufficient suction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the invention content, characteristics and effects of this patent, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

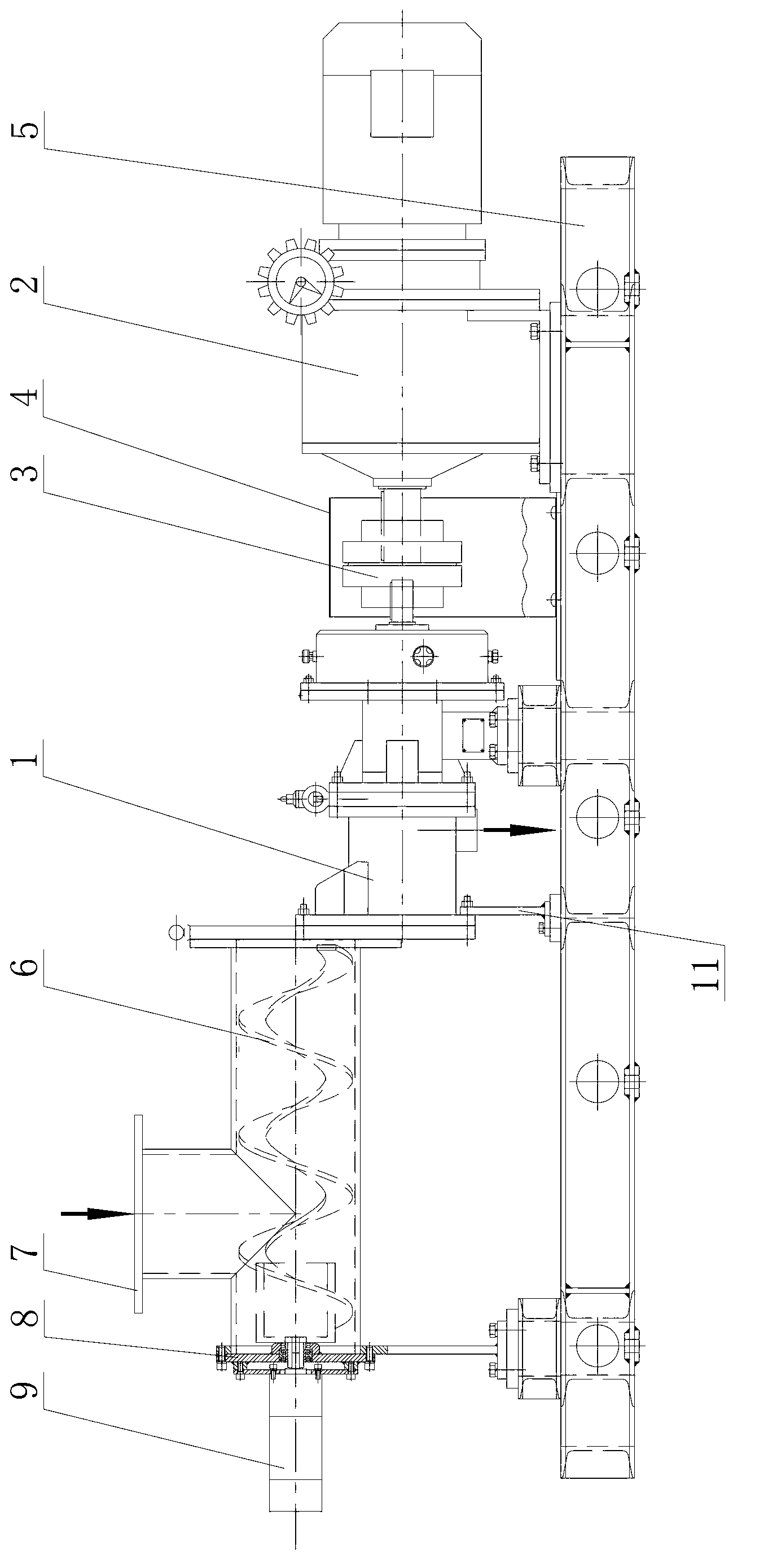

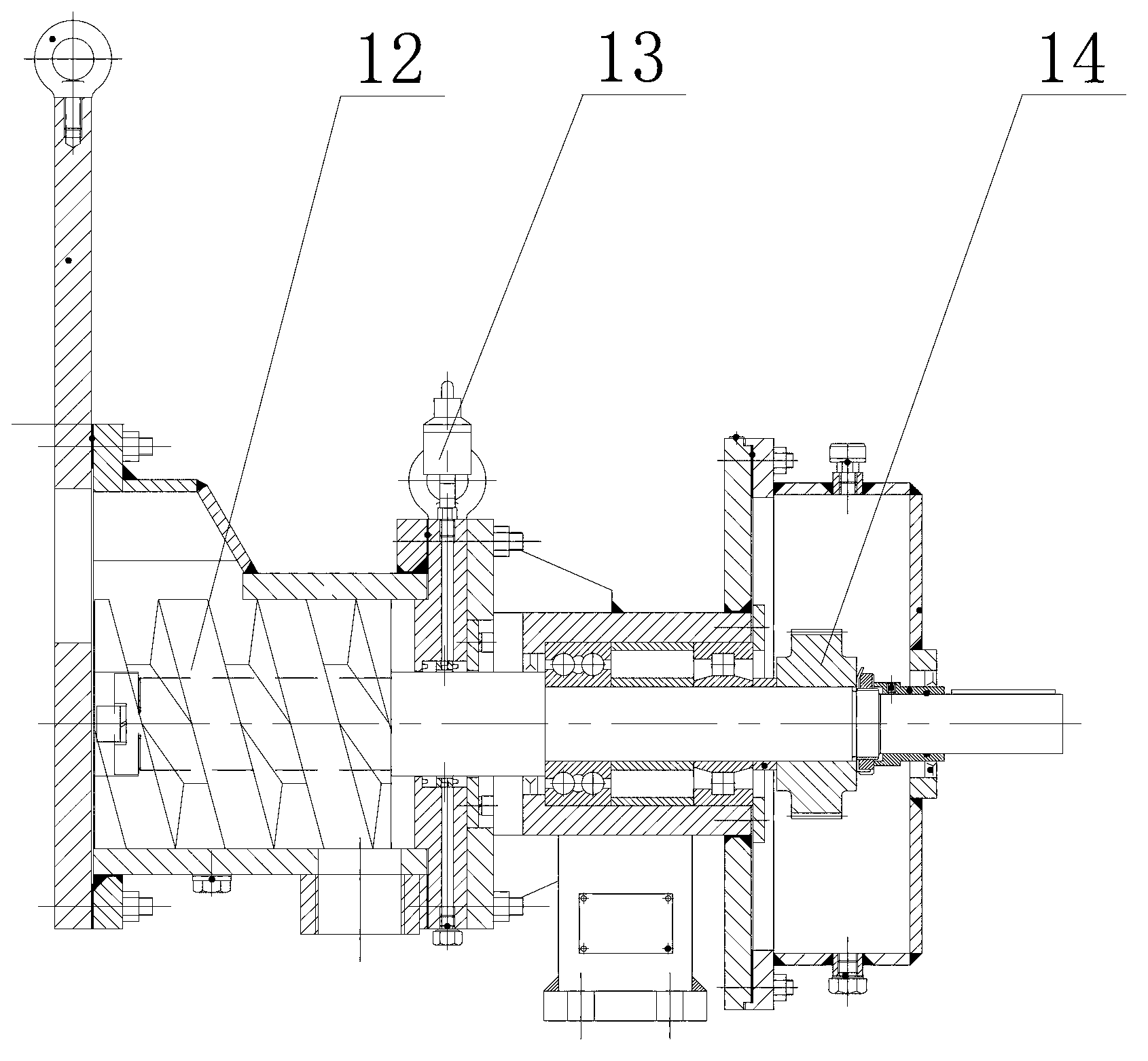

[0019] see Figure 1 to Figure 2 ,

[0020] A twin-screw pump system for conveying emulsion explosives, including a twin-screw pump with external bearings 1, the twin-screw pump with external bearings is connected to an explosion-proof deceleration motor 2 through an elastic coupling 3, and a coupling is also provided on the outside of the elastic coupling device shield 4,

[0021] Also includes a screw propeller 6, the screw propeller is contained in the propeller housing 7, the lower part of the screw propeller 6 and the propeller housing 7 have a small matching gap, which is convenient for pushing the viscous material at the bottom of the propeller housing And discharge the air mixed in the medium. The screw propeller is connected to the propelle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com