Clutch fork with socket structure

A clutch fork and socket technology, applied in the clutch field, can solve the problems of increased wear of the support ball and socket, customer complaints, failure to achieve dustproof effect, etc., to eliminate sharp abnormal noise and solve limit effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

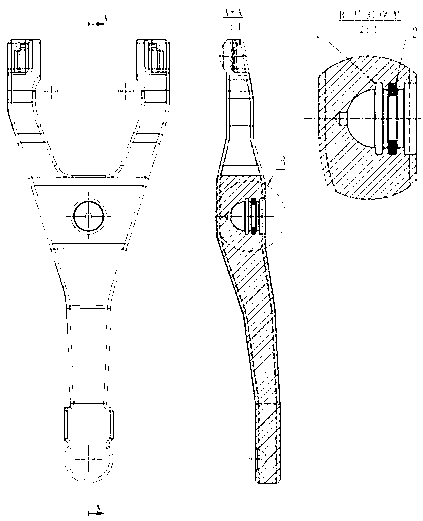

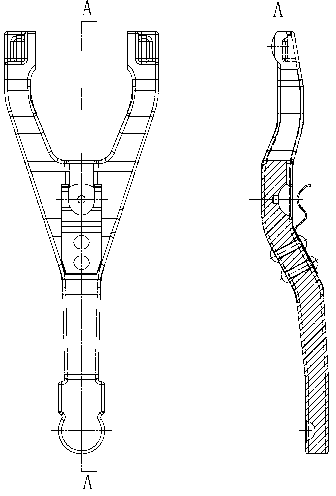

[0014] Example: see figure 1 , figure 2 .

[0015] A clutch shift fork with dimple structure, in which an oil groove 1 is added in the dimple of the clutch shift fork.

[0016] The oil tank 1 is an annular oil tank.

[0017] There are two annular oil grooves.

[0018] Add a rubber sealing ring 2 in the annular oil groove near the outside.

[0019] The inner diameter of the rubber sealing ring 2 is the same as the outer diameter of the support ball head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com