Image-based micro-chemical process liquid level detecting method

A liquid level detection and micro-chemical technology, applied in liquid/fluid solid measurement, measurement device, liquid level indicator, etc., can solve problems such as liquid level measurement, and achieve the effect of fast speed, high precision and accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

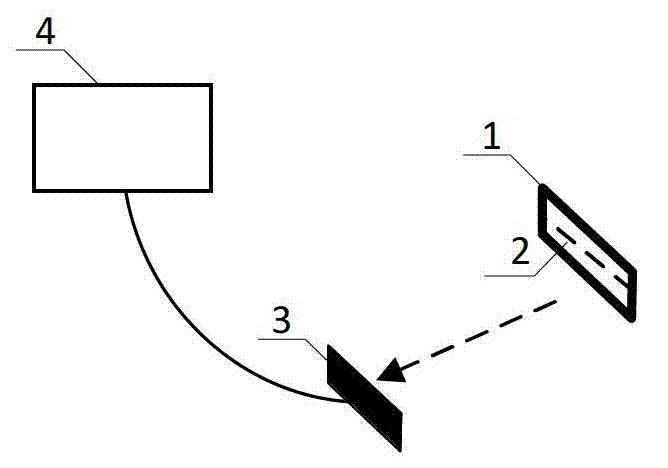

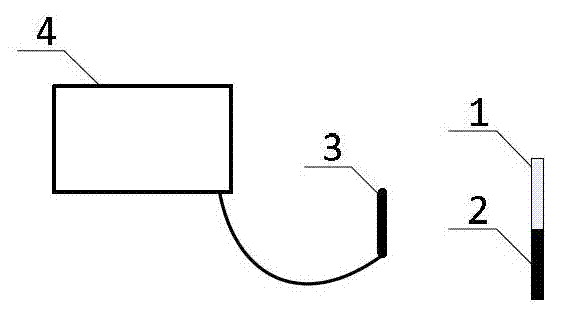

[0016] The specific implementation of the present invention includes two parts, algorithm implementation and device implementation, which will be described in detail below.

[0017] 1 algorithm implementation

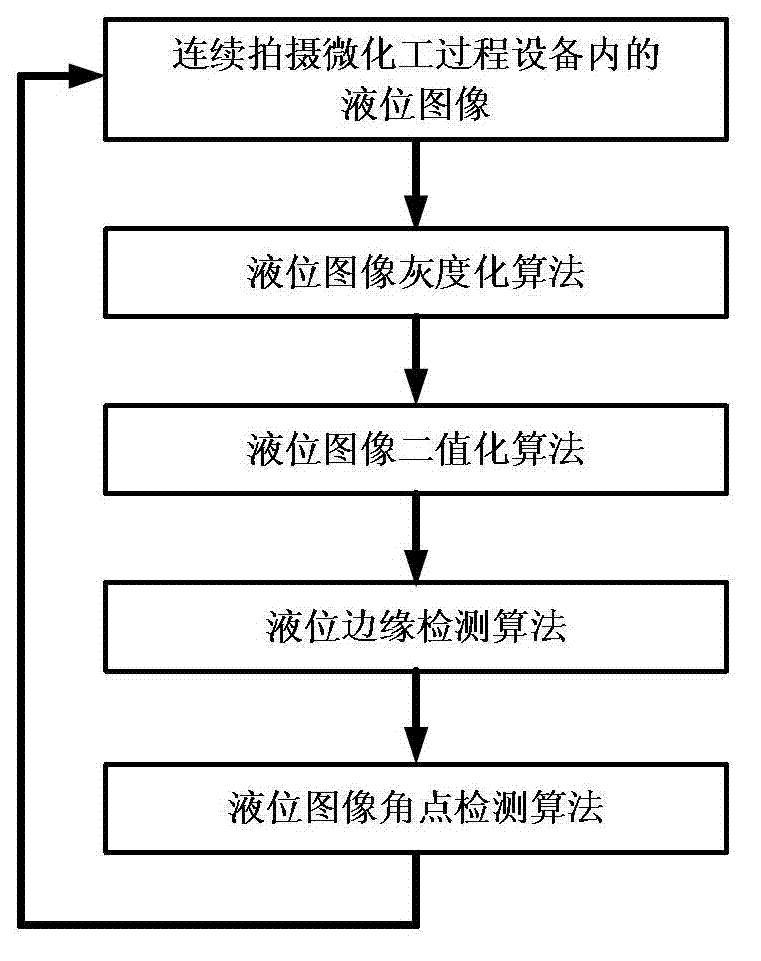

[0018] Such as figure 1 As shown, the algorithm of the image-based microchemical process liquid level detection method includes liquid level image acquisition, liquid level image grayscale, liquid level image binarization, liquid level image edge detection, liquid level image corner detection, The descriptions are as follows:

[0019] 1.1 Liquid level image acquisition, liquid level image grayscale and liquid level image binarization

[0020] The image data is collected by the image collection device to the image processing device. If the collected image is a liquid level array, the image needs to be segmented to obtain a single liquid level image. Generally speaking, the collected image is an RGB image, so it is necessary to convert the collected RGB image into an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com