Determination method for secondary electron emission coefficient of metal surface of microwave component

A technology of secondary electron emission and metal surface, which is applied to high-power microwave components and determines the secondary electron emission coefficient of the metal surface of microwave components, which can solve the problems of large error in calculation results and lack of processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

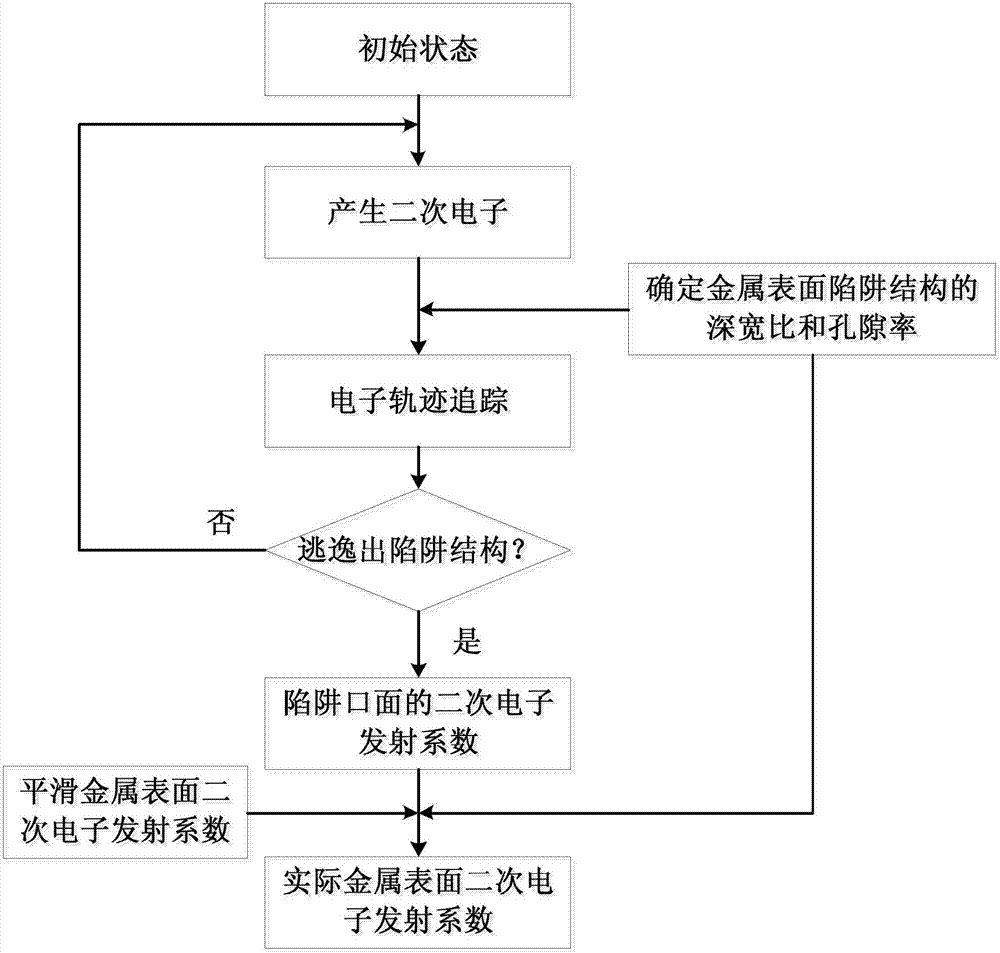

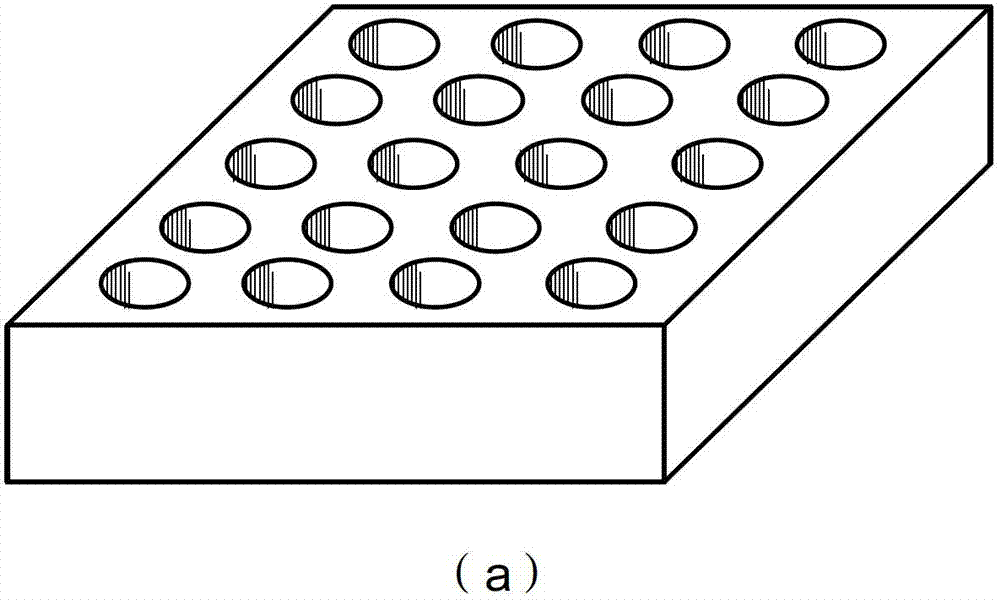

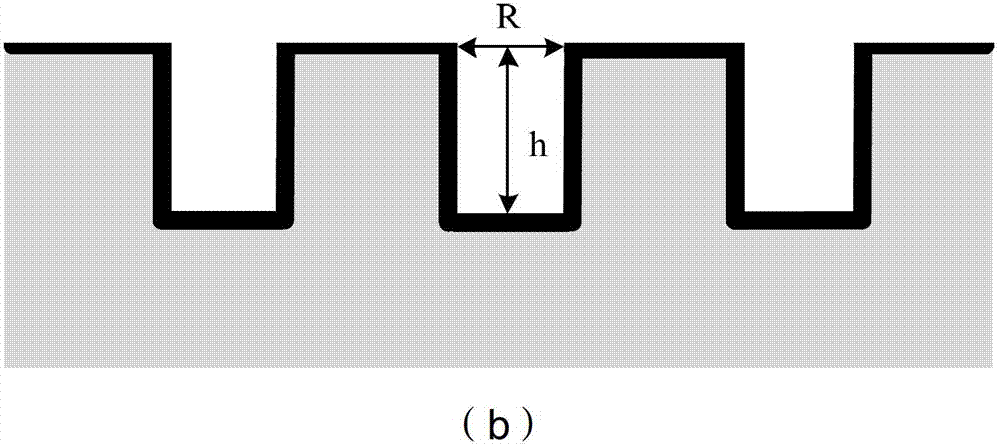

[0050] The invention provides a method for determining the secondary electron emission coefficient of the metal surface of the microwave component, such as figure 1 As shown, the steps are as follows:

[0051] (1) Set the initial energy of the incident electron as E p , the incident angle is θ p ; The initial energy E of the incident electron p The range of values is (0eV, 2500eV), the incident angle θ p The range is (0, 90°).

[0052] (2) Change the initial energy E of the incident electron p , count the number of emitted electrons under different incident energies, and obtain the secondary electron emission coefficient δ of the metal surface flat . Specifically:

[0053] There are N initial electrons with initial energy E p , N is a positive integer, every time each incident electron collides with a smooth metal surface, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com