Method for controlling rotating speed of cold rolling flying shear motor

A technology of motor speed and control method, applied in the direction of self-adaptive control, automatic control device, general control system, etc., can solve the problems of heavy workload, damage to the motor and flying shear body equipment, etc., to achieve high speed, good versatility, The effect of high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Technical scheme of the present invention specifically comprises the following steps:

[0027] (1) Solution of blade speed of cold-rolled flying shears

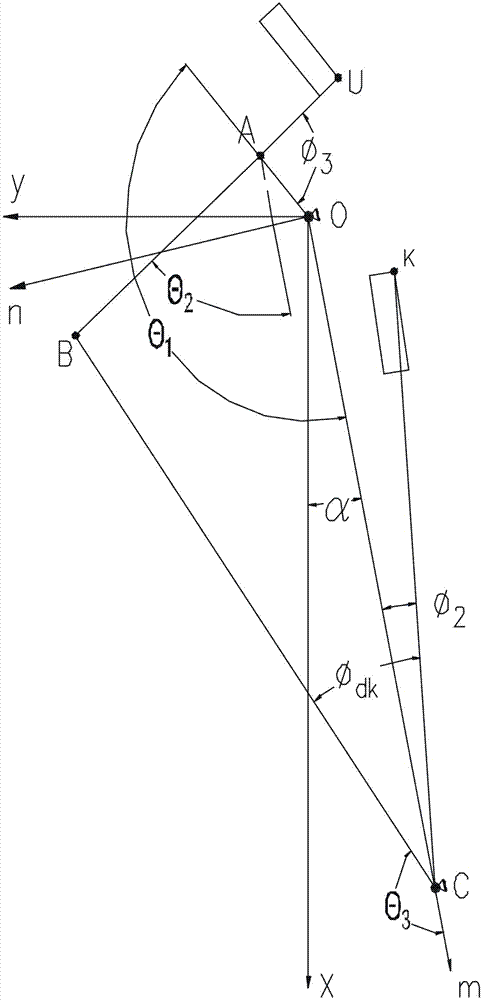

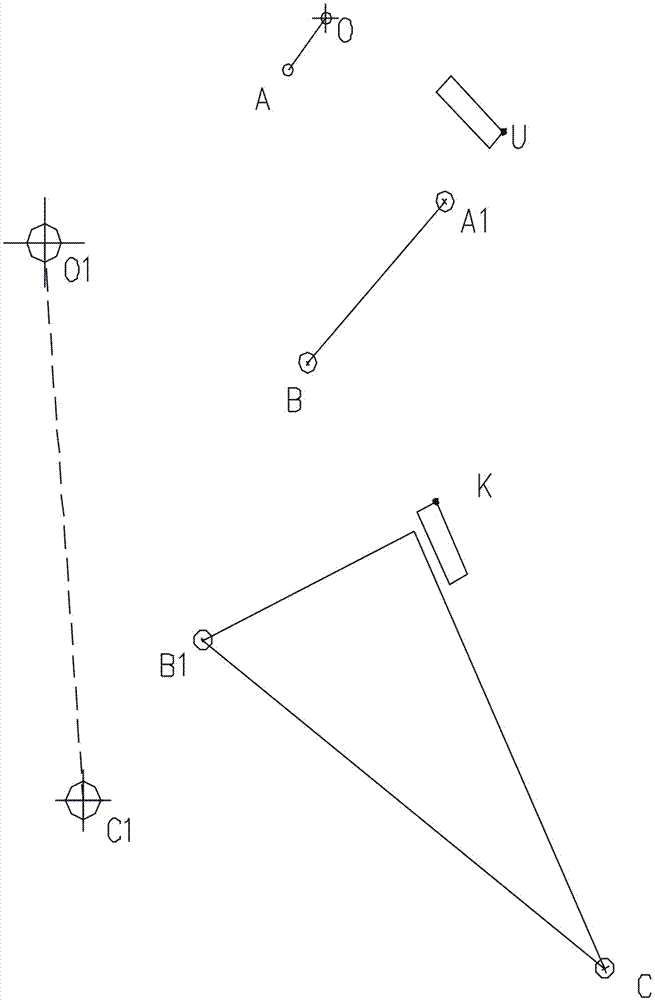

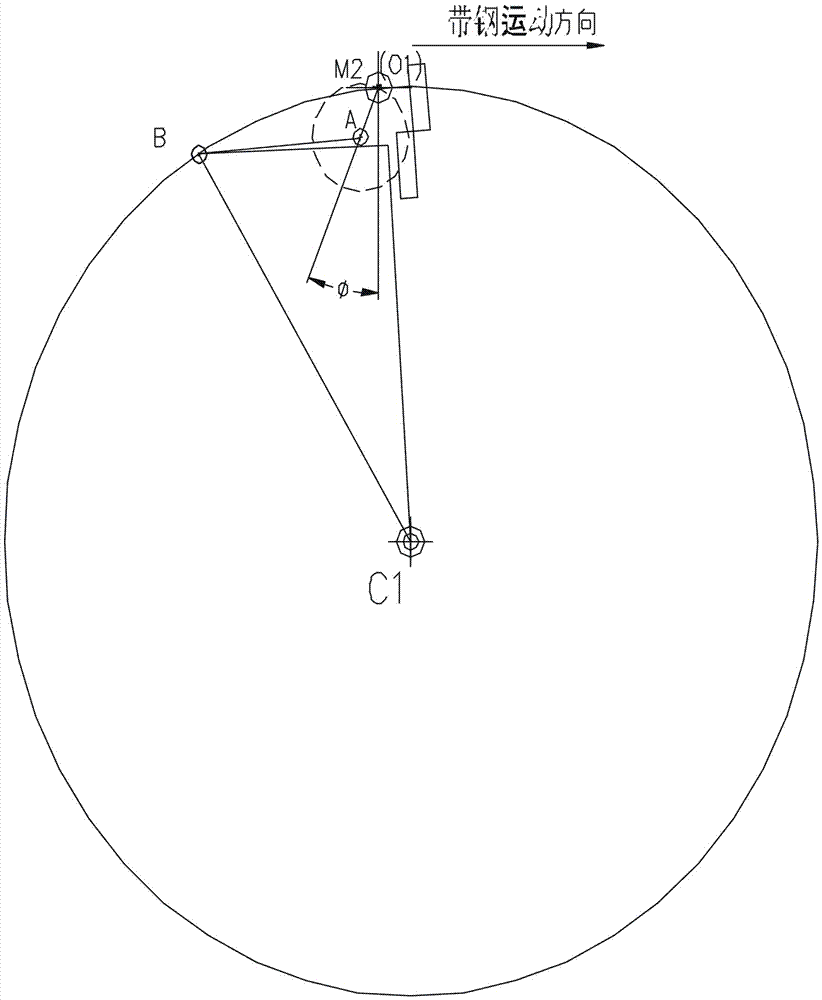

[0028] Schematic diagram of flying shear movement mechanism figure 1 shown. The trajectory of the shear blade can be solved through vector equations and geometric relations. details as follows:

[0029] In the coordinate system mon, apply the relevant knowledge of the vector equation to the quadrilateral OABC:

[0030] (1)

[0031] The equation group (1) is the nonlinear angular displacement equation group of the flying shear mechanism, given the calculation error , using the Newton-Simpson numerical iterative method to solve, we can get and .

[0032] For the U point of the upper scissors:

[0033] (2)

[0034] Through coordinate conversion, the following can be obtained:

[0035] (3)

[0036] Among the above formulas:

[0037] OA ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com