Electronic display board system for production management and display method thereof

A production management and electronic kanban technology, applied in general control systems, control/regulation systems, electrical program control, etc., can solve the problems of high cost, low production efficiency, complex construction, etc., to reduce construction costs and prevent data loss. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings.

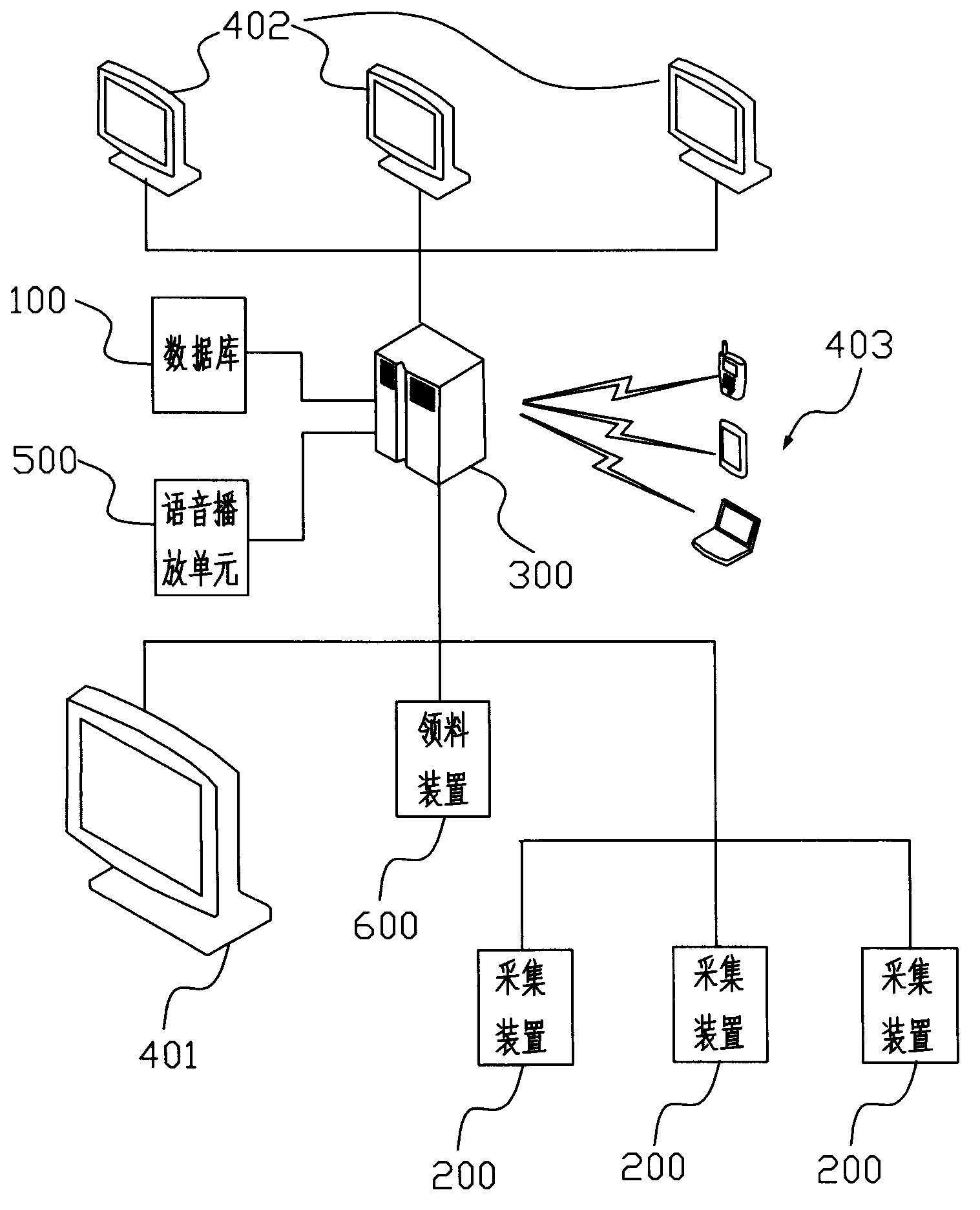

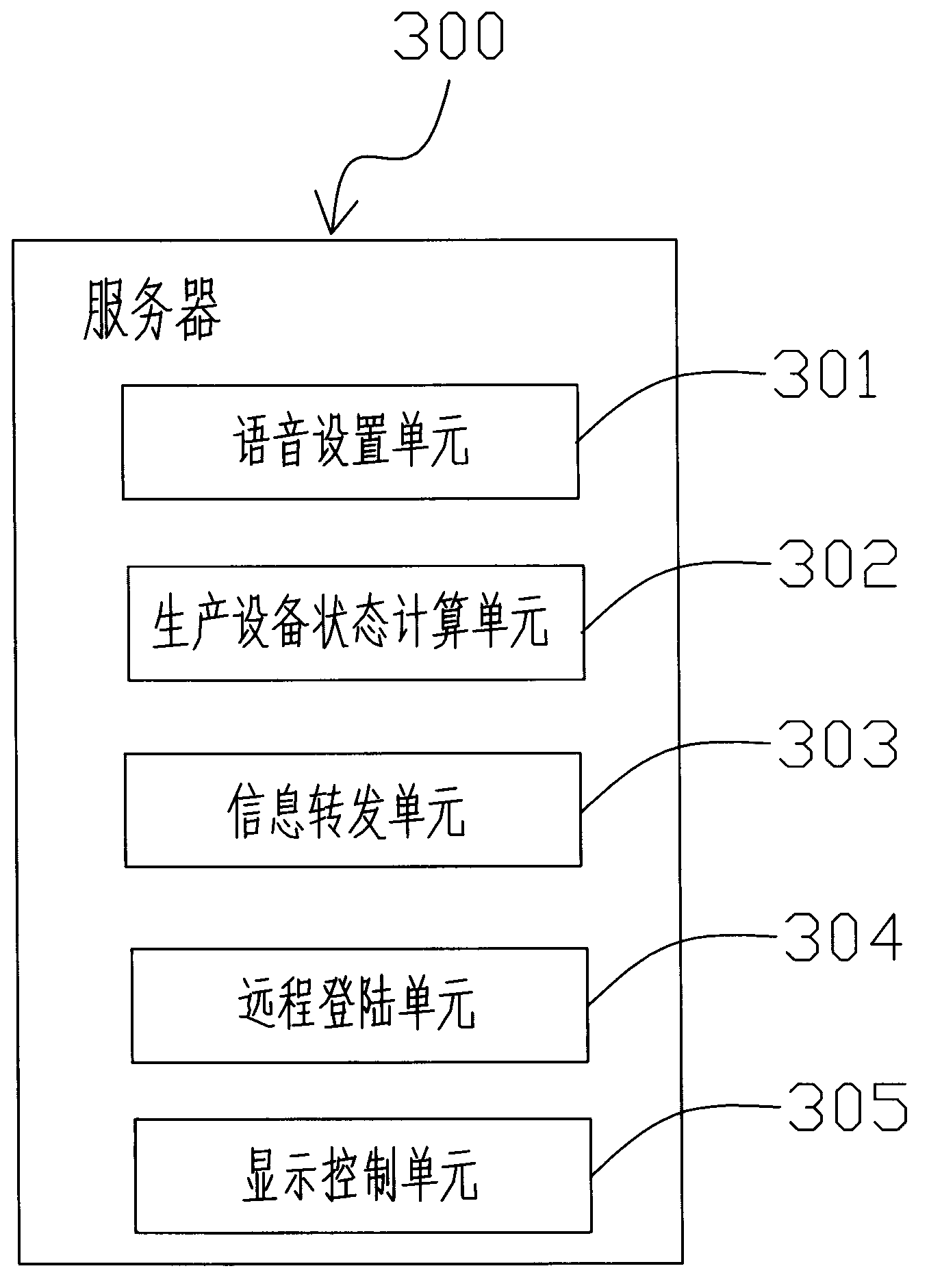

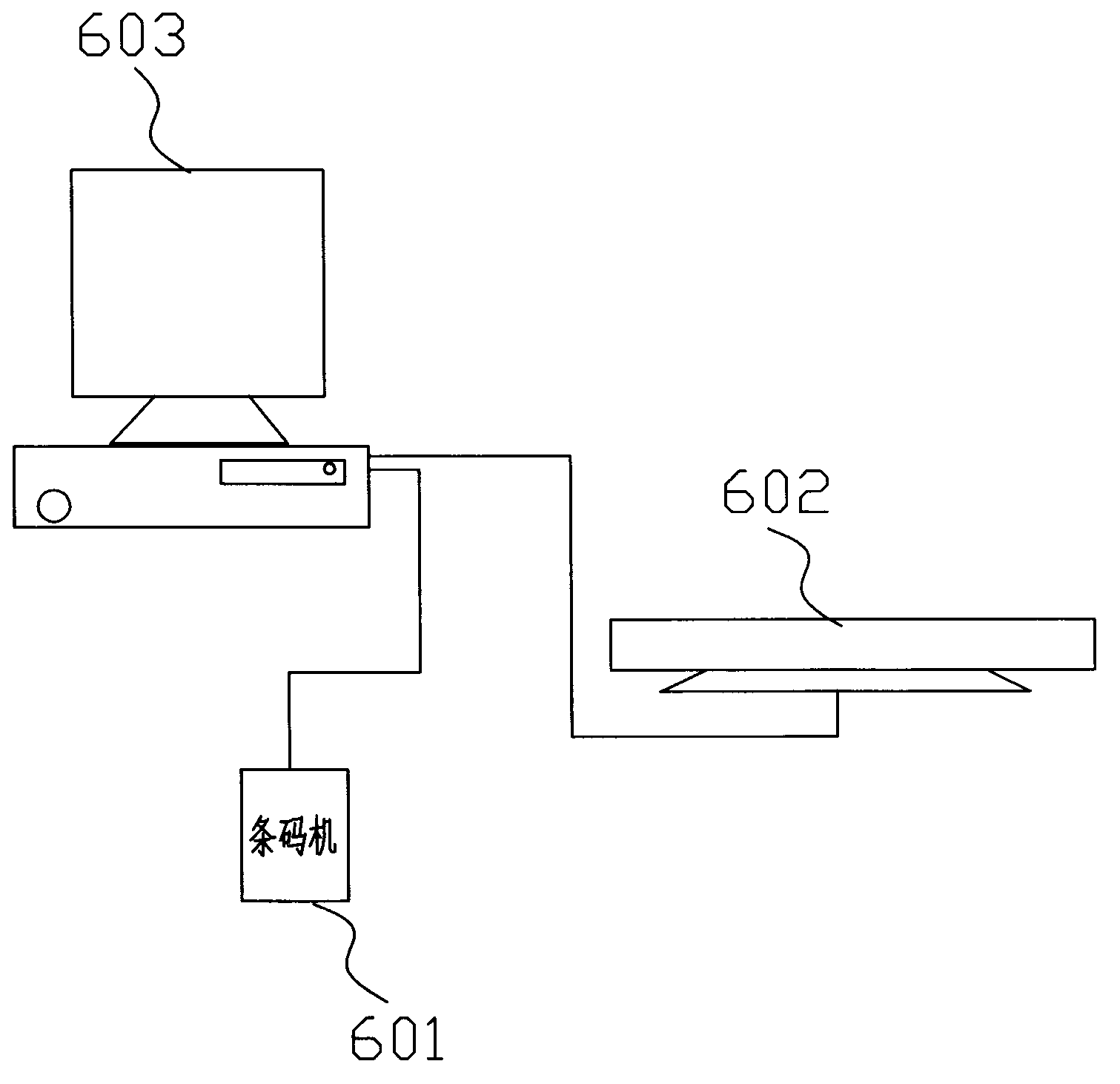

[0052] Figure 1-Figure 3 It schematically shows an electronic kanban system for production management according to an embodiment of the present invention. see figure 1 , an electronic kanban system for production management, which includes: a database 100, an acquisition device 200, a server 300 and a display terminal (401, 402, 403), wherein the database 100, the display terminal (401, 402, 403) and the server 300 are all provided with Fixed network address, database 100, server 300 and display terminals (401, 402, 403) are connected together through the network. The database 100 is used to store the basic data used in the production management of the enterprise; the collection device 200 is used to collect the real-time data of the production equipment at each station of the enterprise. The collection device 200 here can adopt the E3058F or DAM3039F prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com