Apparatus and method for producing packaging

A packaging and composite packaging technology, applied in the field of manufacturing packaging, can solve the problems of reducing process efficiency and increasing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

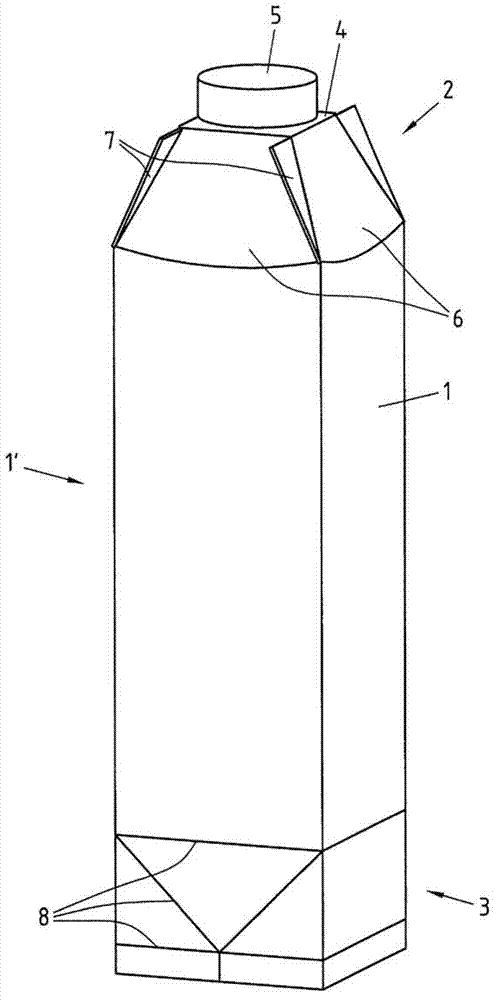

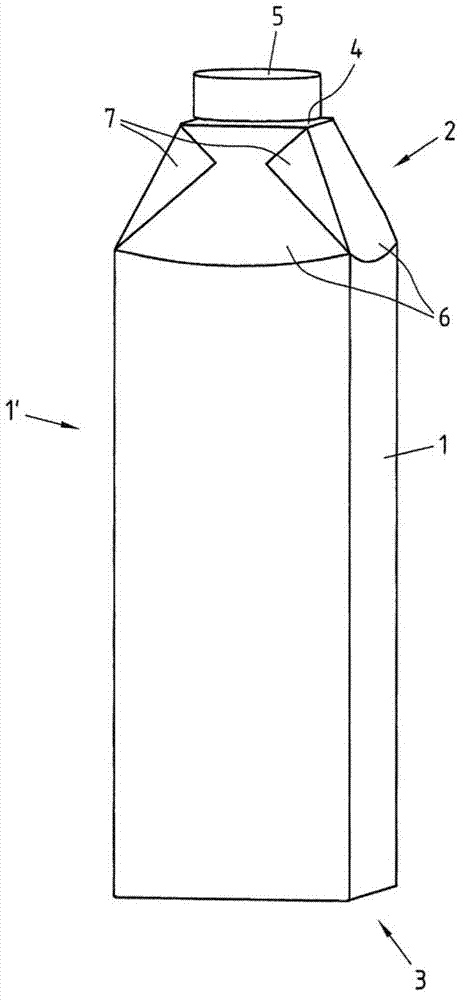

[0048] figure 1 A package 1', closed on one side, manufactured from the casing 1 is shown. The housing 1 has a gable area 2 and a bottom area 3 at its two ends. The package 1' has a square cross-section. The casing 1 is folded regularly from the blank, wherein two edges are joined together to form a tube. While the bottom area 3 remains open, the gable area 2 is closed. so, figure 1 The package 1' shown represents an intermediate stage of the manufacturing process in which the package 1' is first formed from the shell 1 open on both sides and thereafter the filled and closed (ready-for-sale) package is formed.

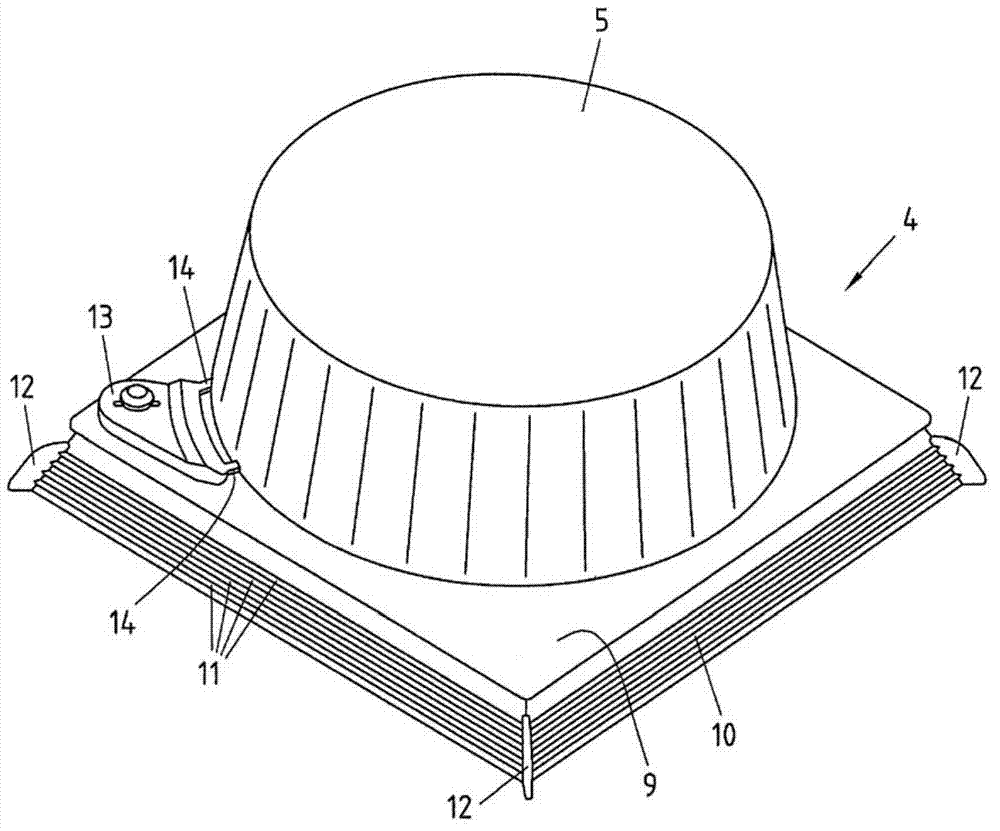

[0049] In the gable area 2 , the housing 1 is connected to a flow-guiding element 4 with a screw cap 5 . exist figure 1 In the illustrated embodiment, the gable area 2 is formed in the shape of a flat-topped pyramid. As a result, the packaging 1' has, in addition to the four gable surfaces 6 in the gable area 2, four bevels 7 protruding from the gable area 2 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com