Rock drilling equipment and transmission method for rock drilling equipment

A kind of equipment and rock drilling technology, which is applied in the field of electric-driven rock drilling equipment, can solve the problems of occupying the space of the carrier and being expensive, and achieve the effects of saving energy, saving costs, and avoiding excessive operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

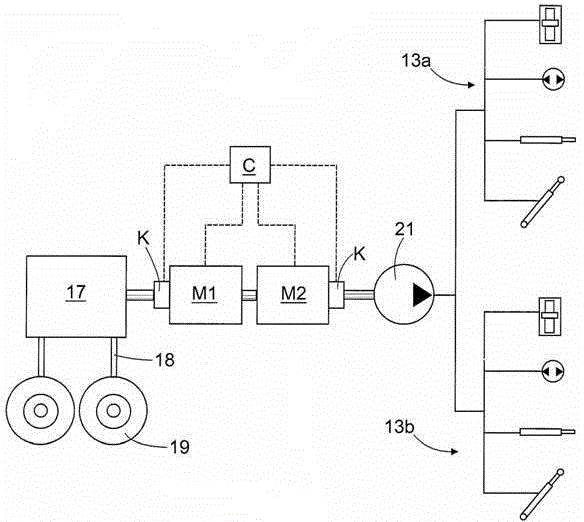

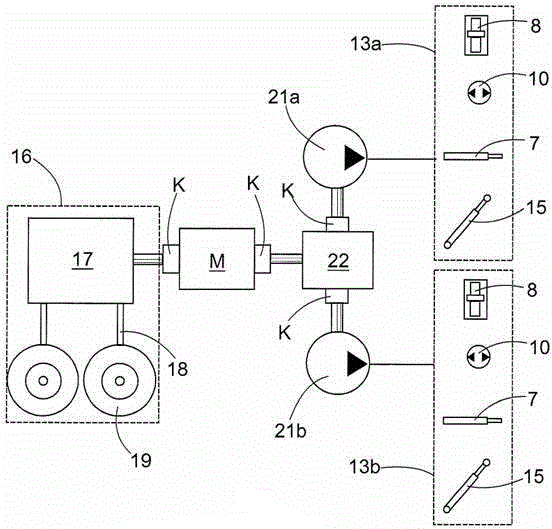

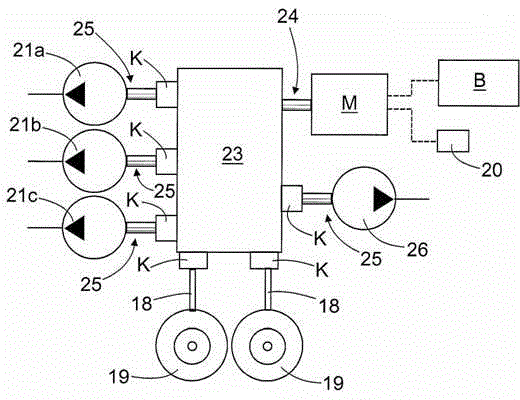

[0031] figure 1 A rock drilling installation 1 is shown comprising a movable vehicle 2 provided with one or more drilling arms 3 a , 3 b equipped with drilling units 4 . The drilling unit 4 can comprise a feed beam 5 provided with a rock drilling machine 6 which can be moved on the feed beam 5 by means of a feed device 7 . The rock drilling machine 6 may comprise percussion means 8 for generating impact pulses on the drilling tool 9 and rotation means 10 for rotating the drilling tool 9 . Furthermore, the rock drilling machine 6 may comprise a flushing device. The arm 3 a shown in the figure and the drilling unit 4 arranged on this arm 3 a are used to drill a borehole in a drilling face 11 of a tunnel or a corresponding drilling site. Alternatively, the arm and the drilling unit on it may be designed to drill fan-shaped boreholes in the roof and walls of rock holes. Furthermore, the rock drilling device 1 can comprise an arm 3 b provided with a rock bolt arrangement 12 whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com