A new type of insulator insulation box for easy maintenance

A technology that is convenient for maintenance and insulators, applied in the direction of electrostatic separation, etc., can solve the problems of long working hours, waste of energy, troublesome maintenance work, etc., to prevent heat loss, save energy, and facilitate installation, maintenance and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

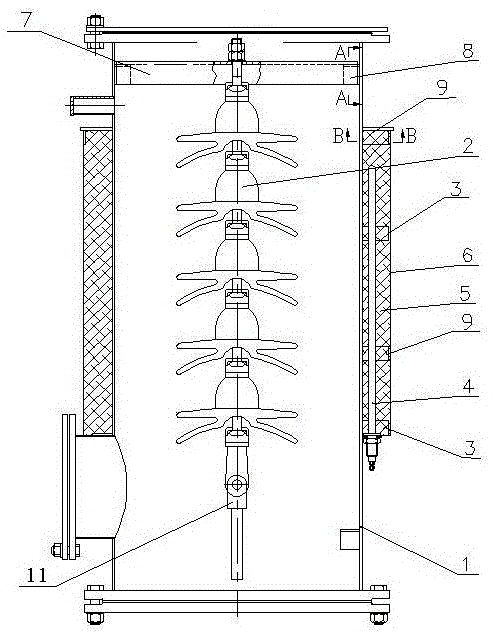

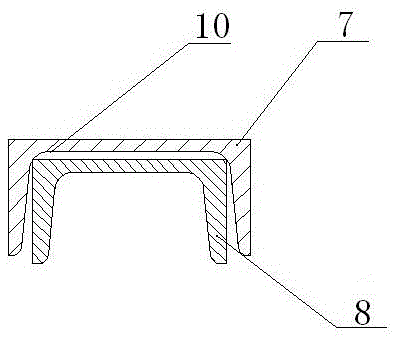

[0017] Such as figure 1 As shown, the convenient maintenance novel insulator insulation box of the present invention includes a box body 1, a heater 4, a suspension beam 7 and an insulator 2, a through hole is arranged in the middle of the suspension beam 7, and the insulator 2 is suspended on the suspension beam 7 by bolts Above, the insulator 2 and the suspension beam 7 are built in the box body 1, and the suspension beam seat 8 is arranged on the upper end of the box body 1, and the two ends of the suspension beam 7 are provided with grooves 10 matching the suspension beam seat 8, and the suspension beam 7 The groove 10 is tightly interlocked with the suspension beam seat 8, thereby ensuring that the suspension beam 7 is not easy to shake under the action of gravity of the insulator 2.

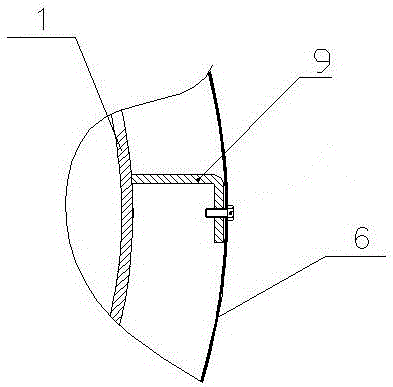

[0018] Heater mounts 3 are arranged at intervals on the outer wall of the box 1, the heater 4 is fixed on the heater mount 3 by bolts, and the heater 4 is wrapped with an insulating layer 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com