Steel-bonded reinforcement method for grid structure

A network frame structure and steel bonding technology, which is applied in building construction, special data processing applications, building maintenance, etc., can solve the problems of steel pipe structure deformation, reinforcement parts and original rods cannot form an integral structure, etc., to extend the network frame Life expectancy, reduced impact on normal business operations, and ease of construction and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

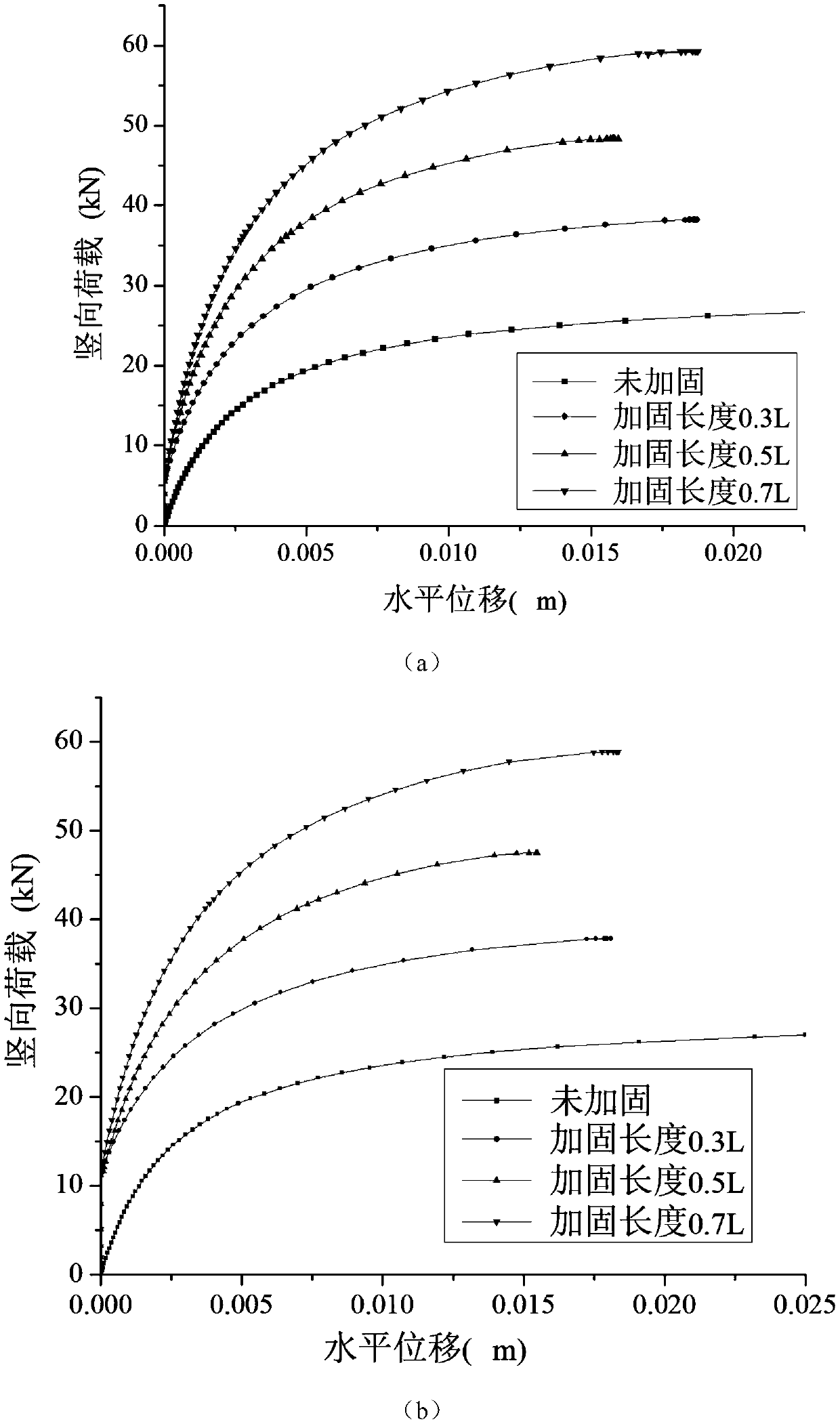

[0072] A method for improving the safety performance of an existing space grid structure will be further described in detail below in conjunction with specific examples. These examples are only for the purpose of comparison and explanation, and the present invention is not limited to these examples.

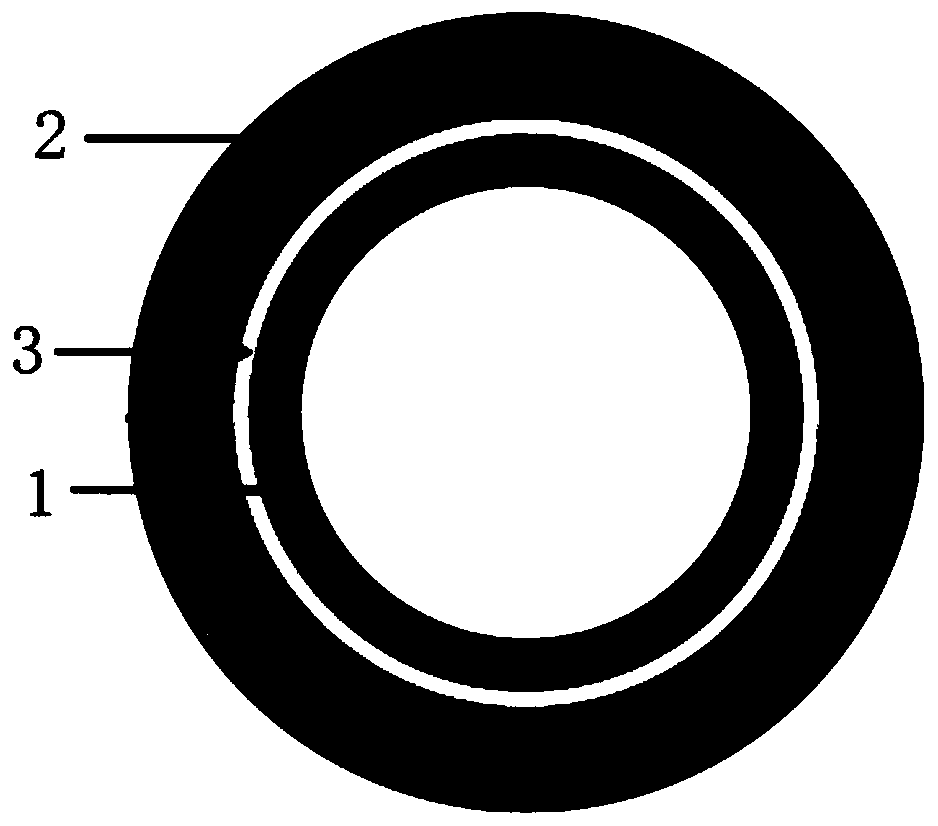

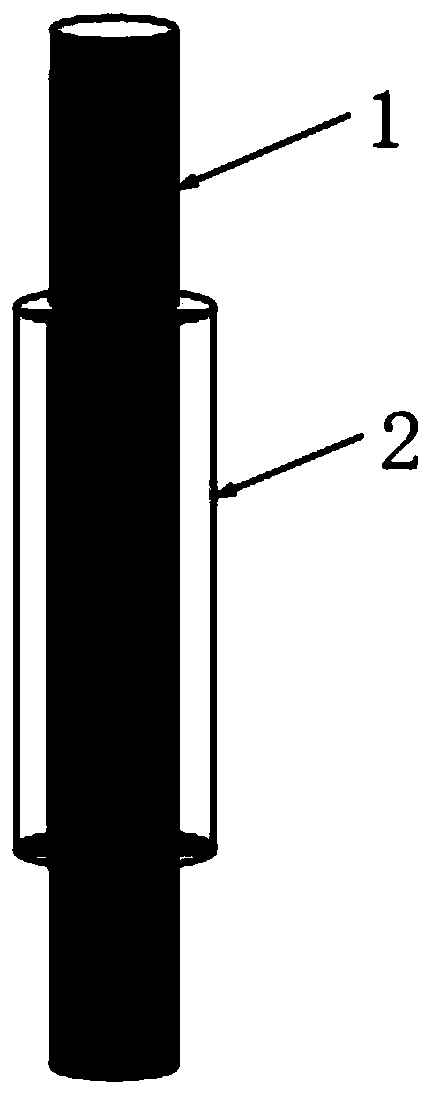

[0073] A specific embodiment of the present invention, a kind of bonding steel reinforcement method for grid structure, Figure 1-Figure 2 shown, including the following steps:

[0074] S1. Confirm that the rod to be reinforced in the grid is the original rod 1; the original rod is a grid structure rod with bending deformation defects;

[0075] S2. Obtain the diameter d, deflection-span ratio, cracking degree and corrosion condition of the original rod 1;

[0076] S3. Determine the value of the damage degree S of the reinforced rod according to the deflection-span ratio, cracking degree and corrosion situation of the original rod 1;

[0077] As shown in Table 1, when the deflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com