Miniature press

A press and micro technology, applied in presses, metal processing, metal processing equipment, etc., can solve the problems of limited pressurization stroke, waste of time, manpower and financial resources of gas-liquid booster cylinders, and achieve compact structure and operation. Diversified, small size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

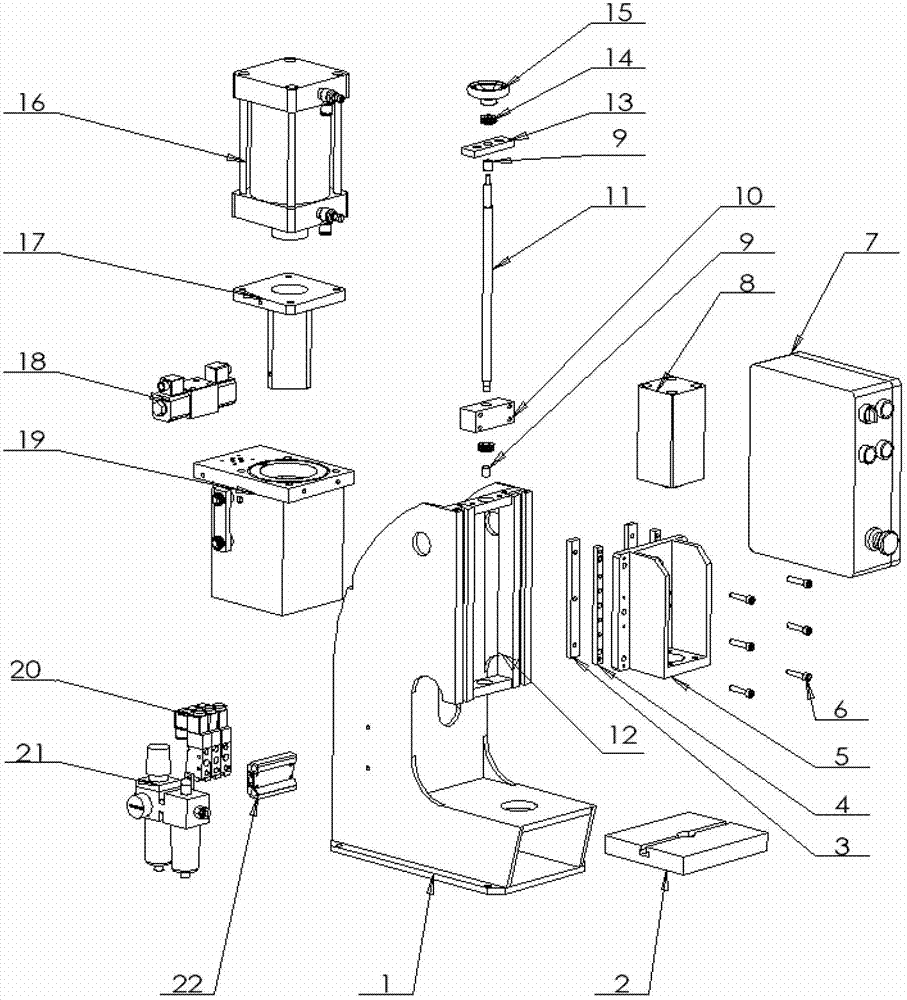

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0025] see figure 1 , the present invention provides a micro-press, comprising a frame 1, an oil tank 19, a cylinder 16, a hydraulic cylinder 8, a supercharging device 17, a slide 5, a lifting block 10 and an electrical control device, wherein the supercharging device includes Booster cylinder, first gas circuit and first oil circuit.

[0026] see figure 1 , the frame 1 includes a base and a body connected to the base, the cross section of the body is arc-shaped, and the free end of the body is provided with a T-shaped slot 12; Panel 2.

[0027] see figure 1 , the fuel tank 19 is equipped with a second air circuit and a second oil circuit, and the cylinder 16 and the booster device 17 are fit and installed on the mounting plate of the fuel tank 19 and then fixed in the frame 1, The piston rod o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com