A solar photovoltaic roof tile assembly

A photovoltaic roof tile and solar energy technology, which is applied in the field of solar energy systems, can solve the problems of poor waterproofness, high cost, and lack of consideration for the disassembly and maintenance of roof tile components, and achieves the effect of quick installation or disassembly, and easy disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

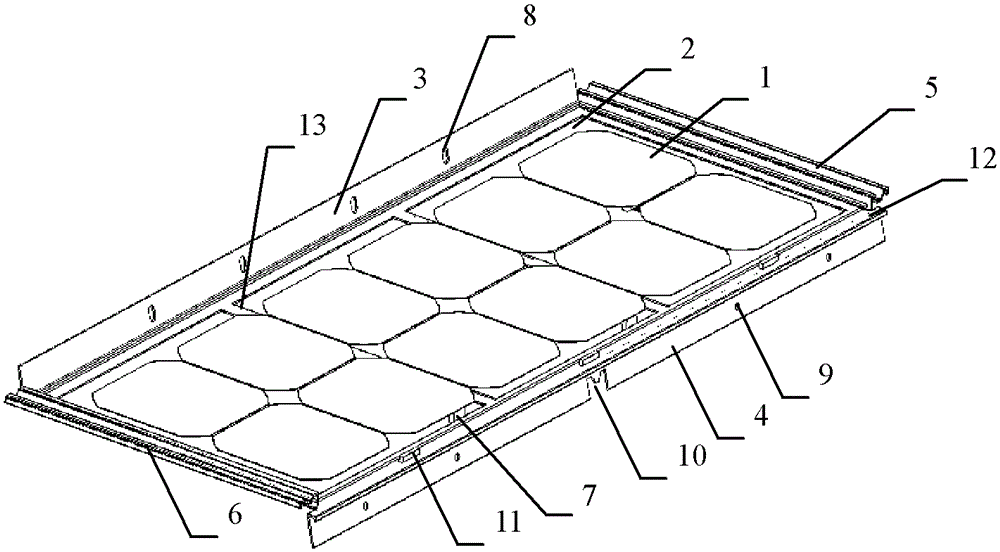

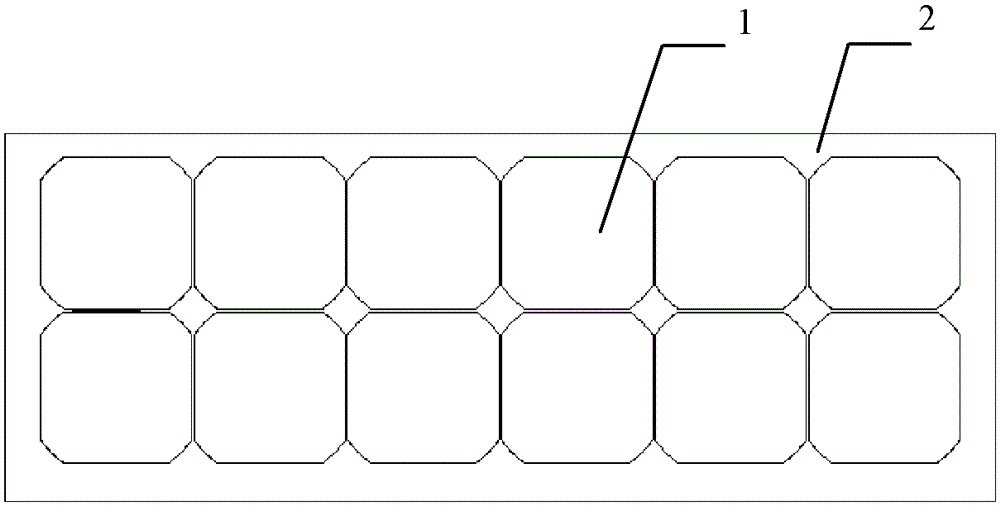

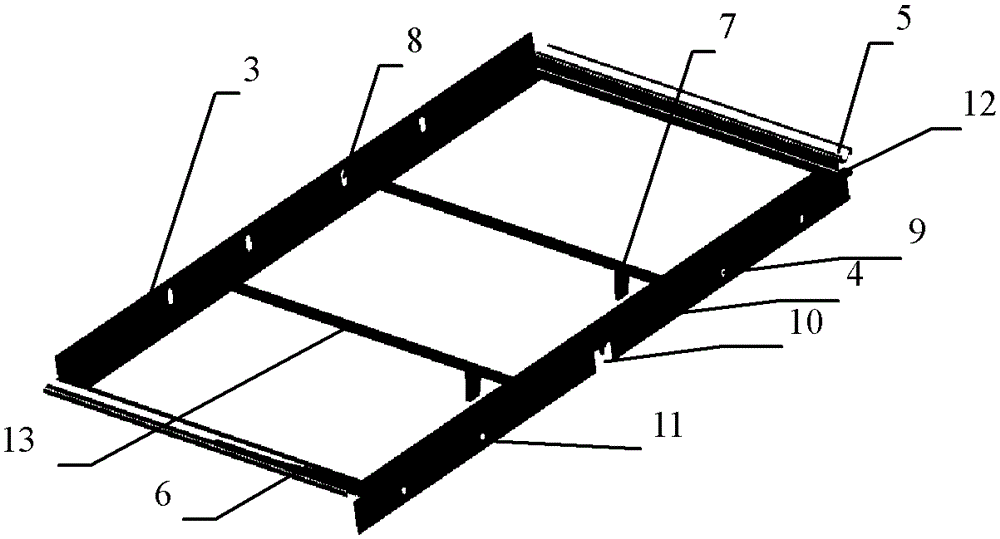

[0028] Such as Figure 1-4 As shown, a solar photovoltaic roof tile assembly includes a laminate and a supporting base. The laminate is packaged by crystalline silicon cells, transparent photovoltaic EVA, photovoltaic TPT backplane, tempered glass and photovoltaic junction box. The specific processing process of the laminate is as follows: first, a single crystalline silicon cell 1 is welded to a welding strip 2 (tin-coated copper strip), and then every six cells are welded into a string, which is two strings in total. After the two strings of batteries are arranged according to the positive and negative electrodes, the strings are welded and connected with a confluence strip (tin-coated copper strip); the photovoltaic low-iron ultra-white tempered glass, transparent photovoltaic EVA, battery strings, transparent photovoltaic EVA, photovoltaic After the stacking sequence of the TPT back sheet is laid, it is laminated at a certain temperature; the laminated laminates are edge t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com