Multi-stage radial spilt petrochemical engineering process pump

A petrochemical and process pump technology, applied in radial flow pumps, components of pumping devices for elastic fluids, pumps, etc. and other problems, to achieve the effect of reducing inter-stage leakage, simple structure and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

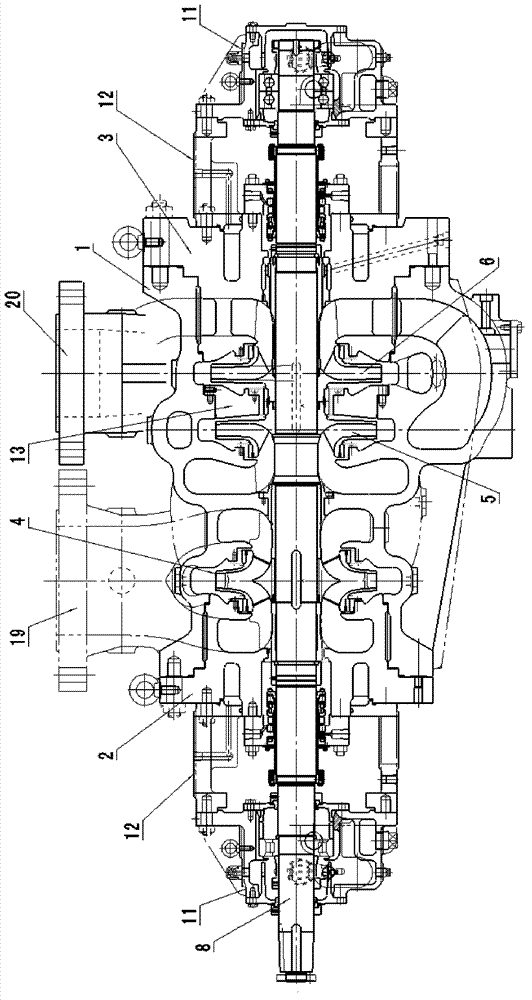

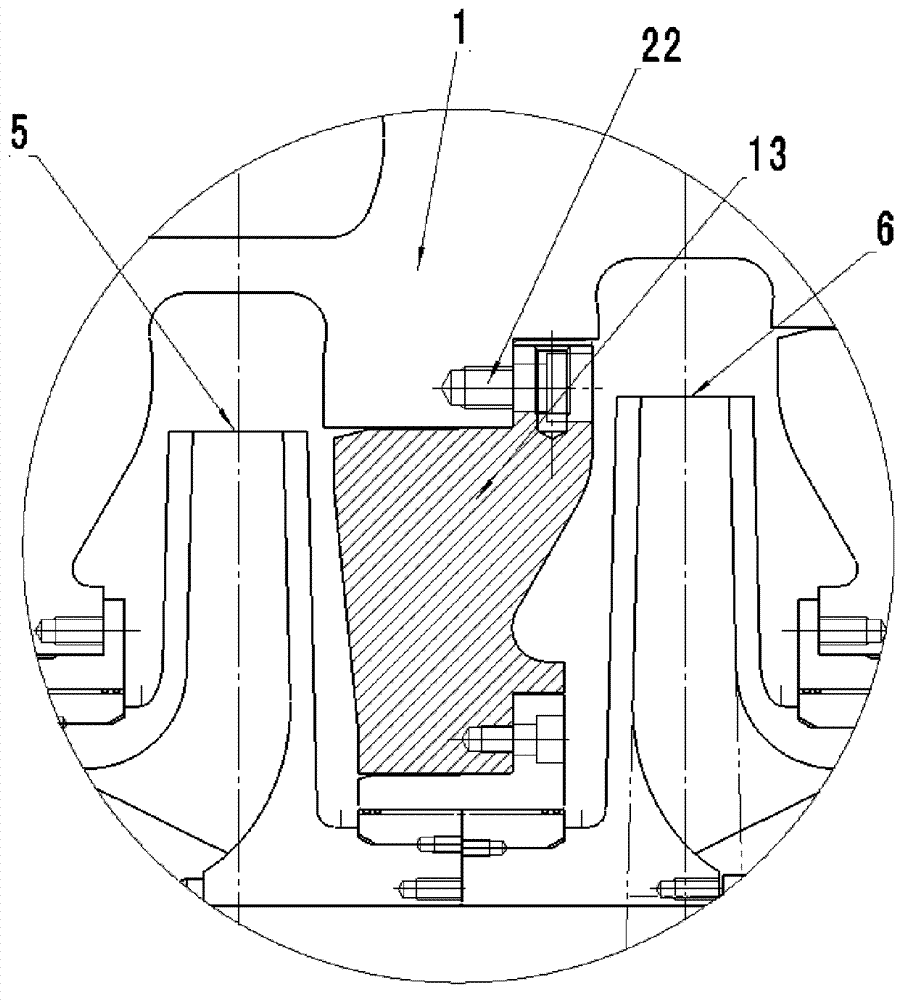

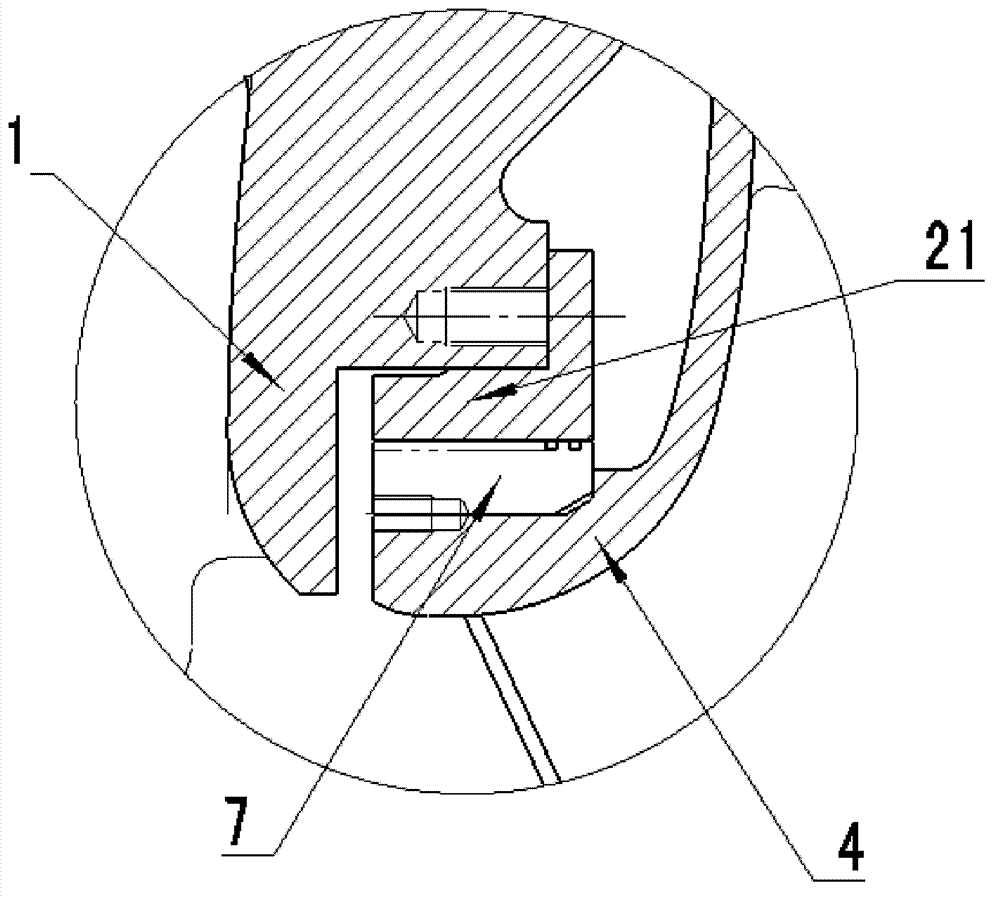

[0030] The invention provides a multi-stage radially split petrochemical process pump, which is supported by the center line, so that when the temperature rises, it can be well centered and reduce the pipeline load. The pump is a three-stage centrifugal structure supported at both ends, and its overall design complies with the tenth edition of the API610 standard. The pump is supported by the center line and radially split. The design maximum operating temperature is 450°C and the standard maximum operating pressure is 10.0Mpa. The direction of the pump inlet and outlet is upward and upward, reducing the equipment space. The pump has a large suction area and good cavitation performance. The shaft seal can be mechanical seal or stuffing seal. The pump transmission adopts a diaphragm coupling with an intermediate extension, and the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com