Light guide plate and manufacture method thereof

A technology of light guide plate and substrate, applied in the directions of light guide, optics, optical components, etc., can solve the problems of low light output efficiency of the light guide plate 120, low brightness of the light guide plate 120, poor light output uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

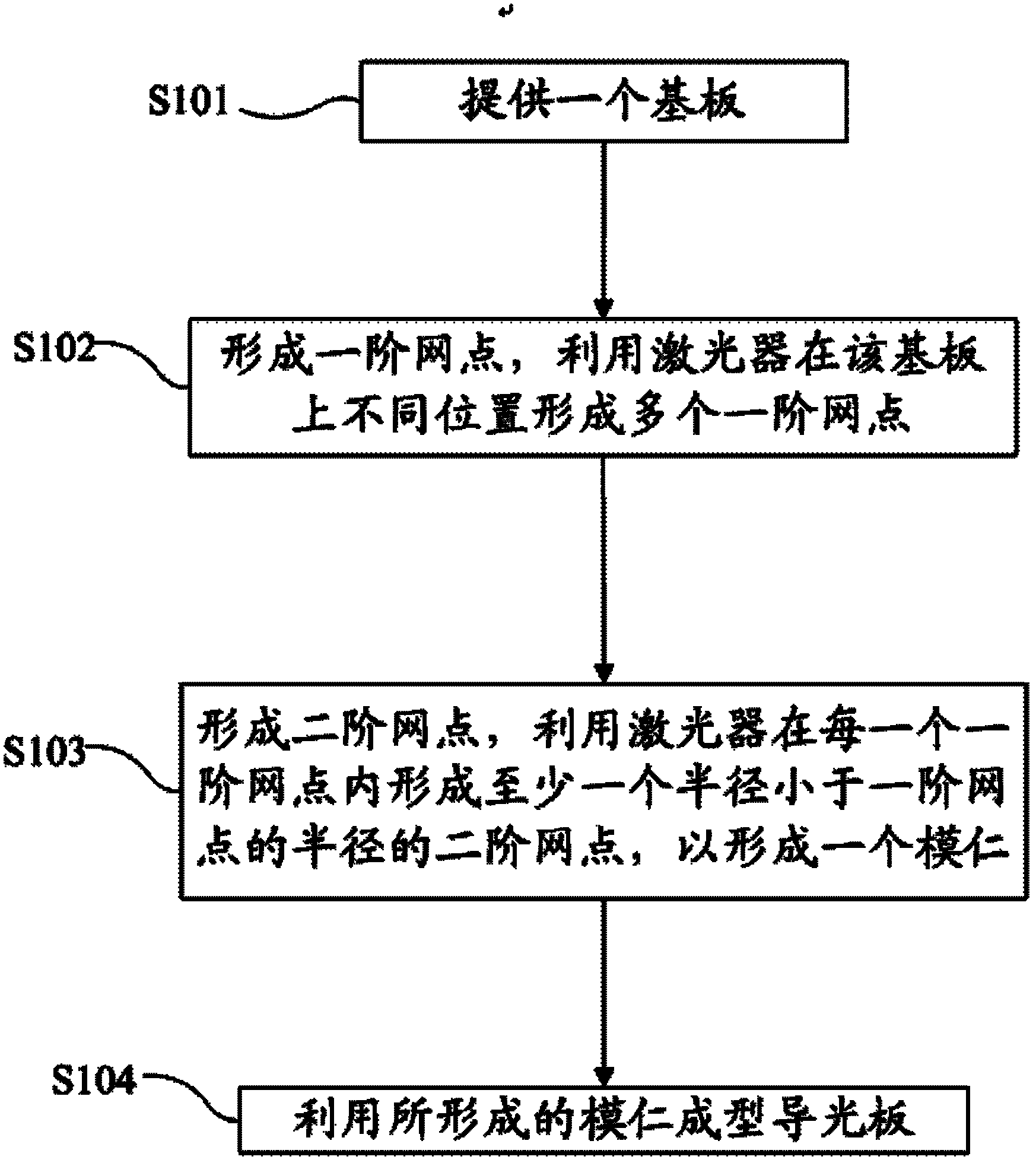

[0030] Please refer to Figure 3-5 , in this embodiment, the method for manufacturing light guide plate comprises the following steps:

[0031] In step S101 , a substrate 210 is provided first, and the substrate 210 is made of metal, preferably steel.

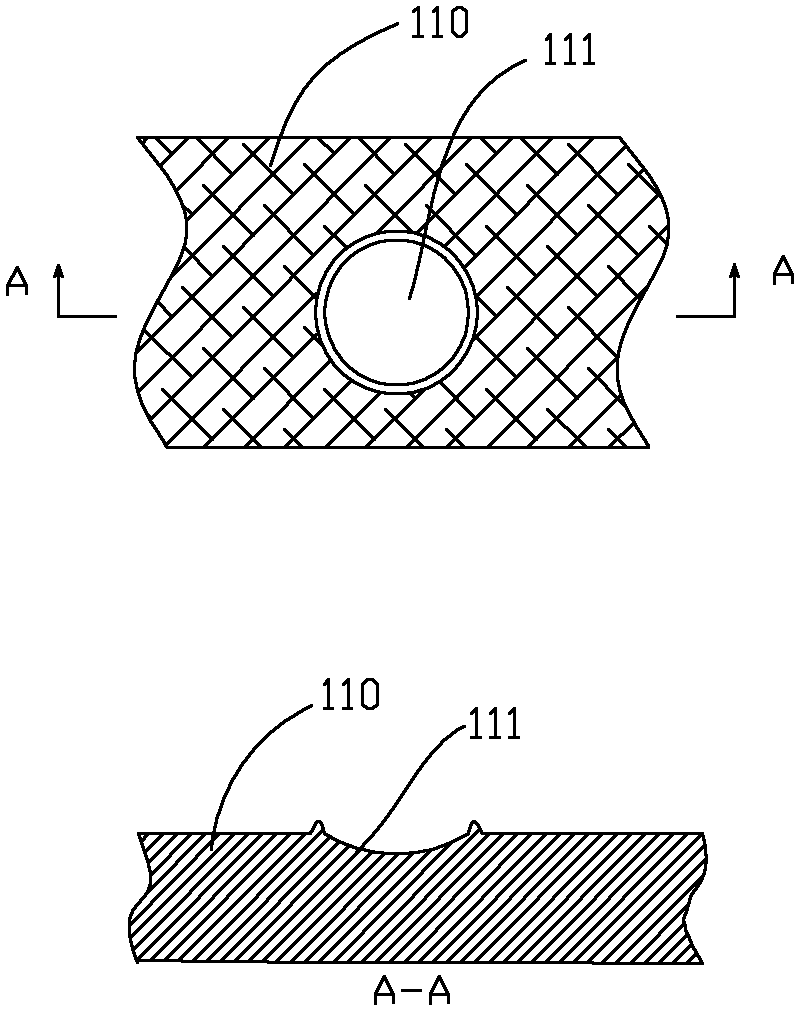

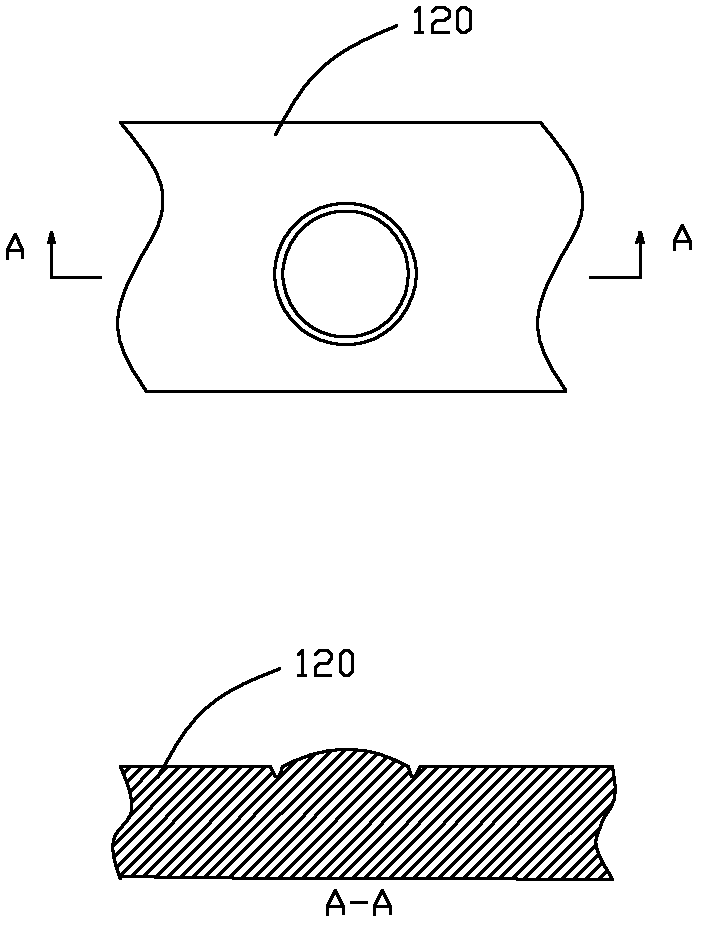

[0032] Step S102, using a laser to print a plurality of first-order dots 211 on the substrate 210, where the laser can be a pulsed laser, and the distribution of the first-order dots 211 on the substrate 210 is designed according to different backlight modules, such as uniform distribution with non-uniform distribution.

[0033] Step S103, using a laser to form a second-order dot 212 in each first-order dot 211, the radius of the second-order dot 212 is smaller than the radius of the first-order dot 211, and the second-order dot 212 is set in the middle of the first-order dot 211. After the first-order dots 211 and second-order dots 212 on the substrate 210 are formed, the mold core is completed. The dots of the mold core inc...

Embodiment 2

[0037] Please refer to Figure 6-8 , the method for forming the light guide plate 320 in this embodiment is similar to that in Embodiment 1, except that a third-order dot is added to the core of this embodiment. In this embodiment, the method for manufacturing a light guide plate includes the following steps:

[0038] Step S201 , providing a substrate 310 .

[0039] Step S202 , using a laser to print a plurality of first-order dots 311 on the substrate 310 .

[0040] Step S203, using a laser to form a second-order dot 312 in each first-order dot 311, the radius of the second-order dot 312 is smaller than the radius of the first-order dot 311, and the second-order dot 312 is set in the middle of the first-order dot 311.

[0041]In step S204 , after forming the first-order dots 311 and the second-order dots 312 inside the first-order dots 311 on the substrate 310 , a third-order dot 313 is formed in the second-order dots 312 by using a laser. The radius of the third-order dot...

Embodiment 3

[0045] Please refer to Figures 9 to 11 , the method of forming the light guide plate 420 in this embodiment is similar to that of Embodiment 1, the difference is that each first-order dot of the mold core in this embodiment is provided with two second-order dots. In this embodiment, the method for manufacturing a light guide plate includes the following steps:

[0046] Step S301 , providing a substrate 410 .

[0047] Step S302 , using a laser to print a plurality of first-order dots 411 on the substrate 410 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com