Zinc-air battery pack capable of being assembled conveniently

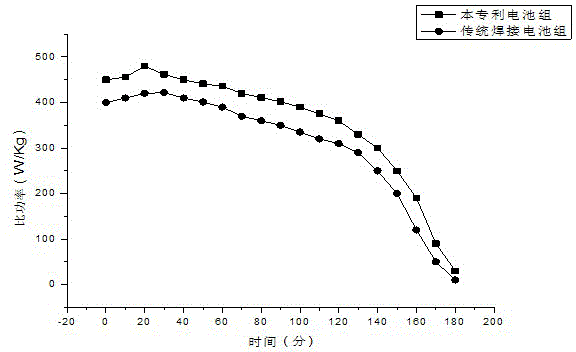

A battery pack, zinc-air technology, applied in battery pack components, circuits, fuel cell type half cells and primary battery type half cells, etc., can solve the problems of slow and inconvenient battery replacement, and save welding. The effect of working hours, increasing replacement speed, and avoiding battery efficiency degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

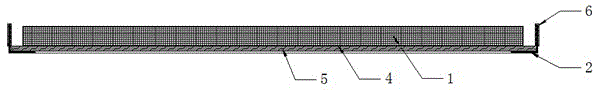

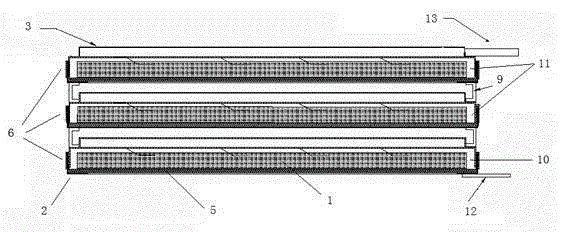

[0021] Such as figure 1 As shown, a zinc-air battery pack that is easy to assemble according to the present invention includes a type A battery 10, a type B battery 11 and a current collector 3, and the type A battery 10 is placed on the upper part of the battery tank 2 with an air electrode 5 , on which the zinc paste 1 is spread through the diaphragm 4, and the air electrode 5 is welded in the battery tank 2 to form the positive electrode 12 of the battery. The lower part of the current collector 3 is equipped with copper claws 8 by welding, and the B-type battery 11 is composed of an A-type battery 10 and the current collector 3 , which are connected by a bipolar connector 9 in the middle. When installed as a whole, the B-type ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com