Dual-purpose cutting device for cutting and separating circuit board

A cutting device and circuit board technology, applied in metal processing and other directions, can solve the problems of difficult quality assurance, irregular cutting, time-consuming and labor-intensive, etc., and achieve the effects of easy processing, prevention of cutting deviation, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

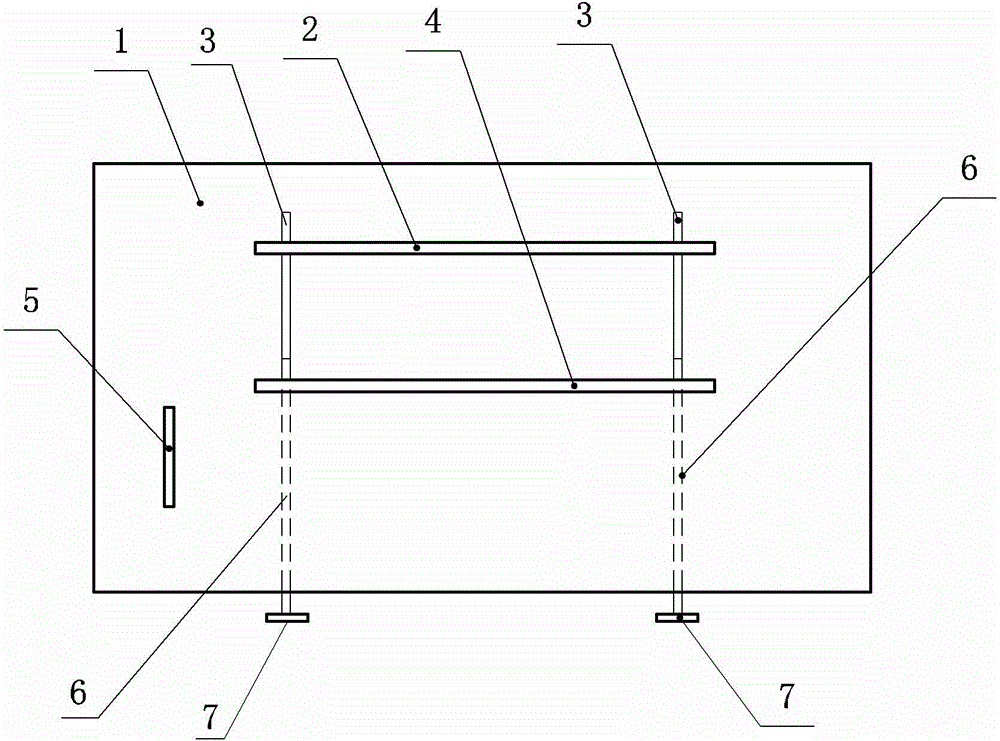

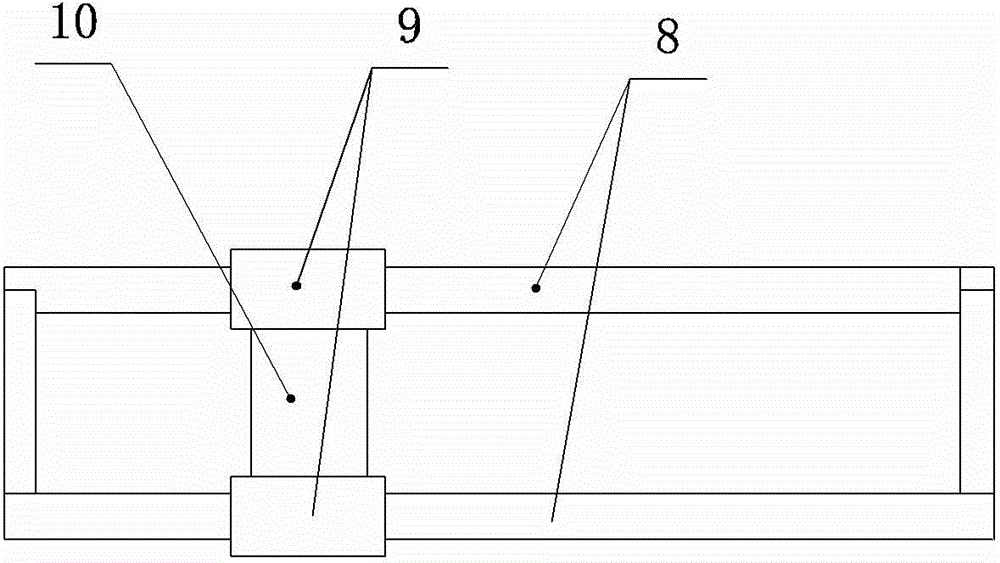

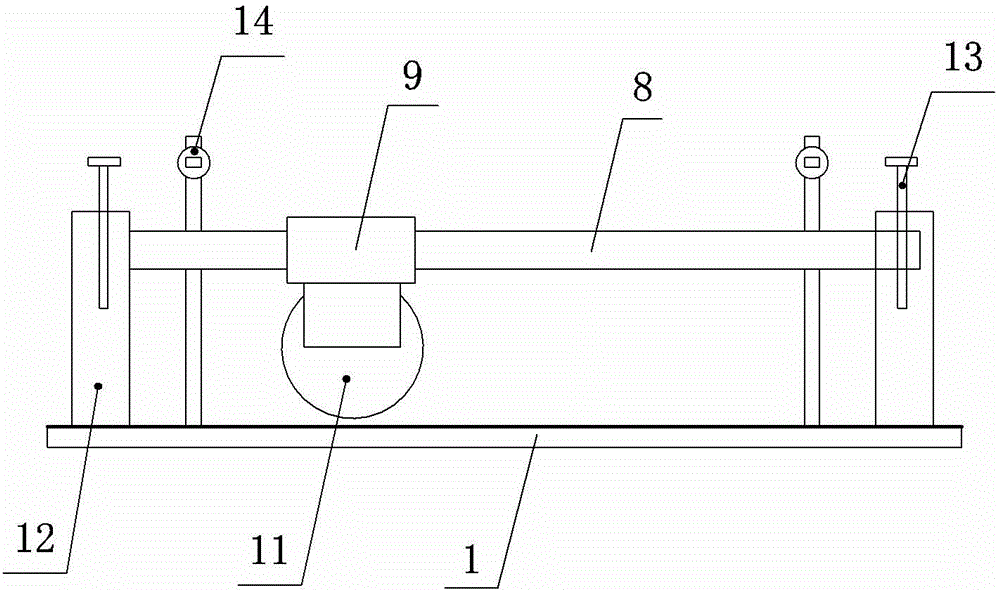

[0023] Embodiment one: see Figure 1 ~ Figure 4 , the circuit board cutting and dividing dual-purpose cutting device of the present invention includes a cutting platform 1, a cutting tool, and a circuit board positioning mechanism. The surface of the cutting platform 1 is provided with a cutting groove 4 for the operation of the cutting tool. Cutting groove direction is provided with slide rail 8, and described slide rail is provided with slide block 9, and cutting cutter is installed on the connecting plate 10 of slide block, can do reciprocating linear motion along slide rail together with slide block, and the blade 11 of cutting cutter Corresponding to the cutting groove, groove-shaped brackets 12 are fixed on the two ends of the corresponding slide rails on the cutting platform. The brackets are respectively provided with adjustment screw 13 for adjusting the up and down movement of the slide rail, and the grooved bracket 12, the adjustment screw 13 and the slide rail 8 co...

Embodiment 2

[0024] Embodiment two: see Figure 1 ~ Figure 4 The circuit board cutting and dividing dual-purpose cutting device of this embodiment is different from the first embodiment in that the circuit board positioning mechanism includes an end positioning baffle 5 arranged on the left side of the cutting platform, and a front positioning baffle 5 on the front side of the circuit board. , the rear positioning baffle 2, the front and rear positioning baffles of the circuit board are movably arranged on the cutting platform, and support rods are respectively provided under the two ends, and two support rod moving grooves 3 are correspondingly provided on the cutting platform A front and rear position adjustment screw 6 linked with the support rod is provided under the cutting platform, and an adjustment handle or an adjustment handwheel 7 with a dial is provided at the end of the adjustment screw.

Embodiment 3

[0025] Embodiment three: see Figure 1 ~ Figure 4 The circuit board cutting and dividing dual-purpose cutting device of this embodiment is different from Embodiment 1 or Embodiment 2 in that the slide rail 8 is two parallel linear guide rails fixed together, and the two ends are fixed by connecting blocks, matching Arranged in the trough-shaped support, two lead screws with rotating handwheels are arranged in cooperation with the connecting blocks at both ends of the slide rail and the trough-shaped support respectively.

[0026] Both sides of the slide rail are equipped with scales or digital display centimeters 14 to show the distance between the slide rail and the cutting platform (that is, the distance between the cutting blade and the cutting platform), so as to control the cutting depth of the circuit board (that is, the V groove depth). The so-called V-groove refers to a small V-shaped groove cut out on the front and back surfaces of the circuit board, along which the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com