Device for shaping press-fitting counterweight for transport vehicle

A molding device and transportation vehicle technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of manpower occupation, quality hidden dangers, and low production efficiency, and achieve the effects of labor saving, high work efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

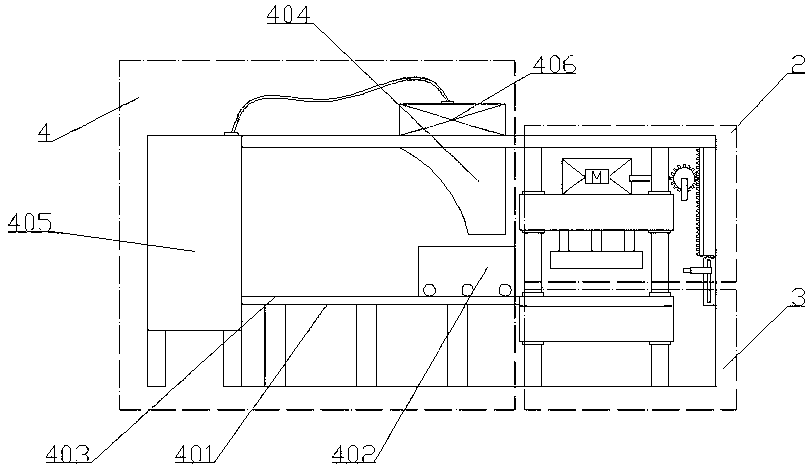

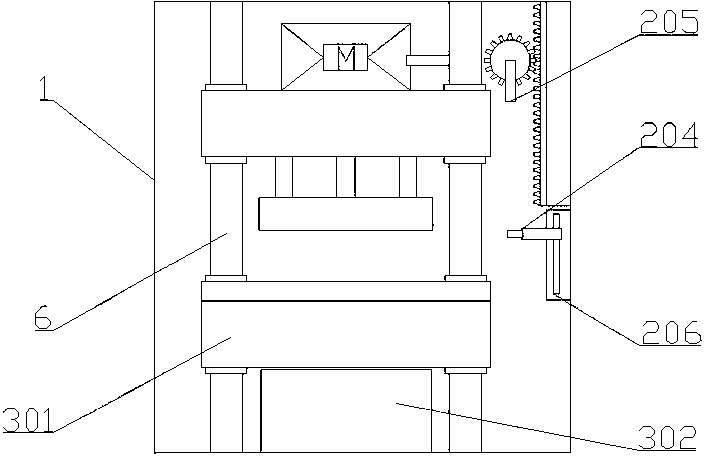

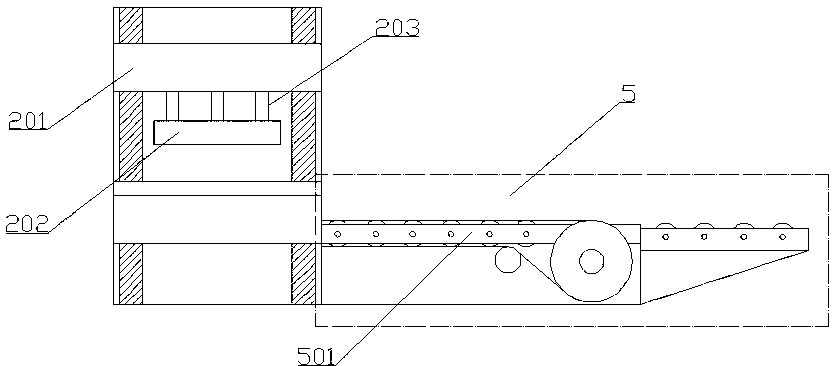

[0020] As shown in the figure: a molding device for press-fitting counterweights for transport vehicles, which consists of a frame 1, a molding mechanism 2, a mold loading mechanism 3, a material feeding mechanism 4 and a finished product output mechanism 5, and the inside of the frame 1 is vertical The direction is provided with four guide pillars 6; The four corners of die-pressing mechanism 2 and die-loading mechanism 3 pass through guide pillars 6 respectively, and die-pressing mechanism 2 and die-carrying mechanism 3 can be vertically relative to machine by guide pillar 6. Frame 1 moves up and down.

[0021] The die mechanism 2 is composed of a die support 201, a pressing module 202, a connecting column 203, a driving device and a stroke control device. The four corners of the die support 201 pass through four guide posts 6 respectively, and the lower end of the die support 201 passes through The connecting column 203 is connected with the pressing module 202, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com