Dust suction nozzle lifting self-locking device

A technology of self-locking device and vacuum nozzle, which is applied in the direction of road cleaning, construction, cleaning methods, etc. It can solve the problems of not being able to lock completely reliably and affect the normal driving of the road sweeper, and achieve the effect of reliable locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

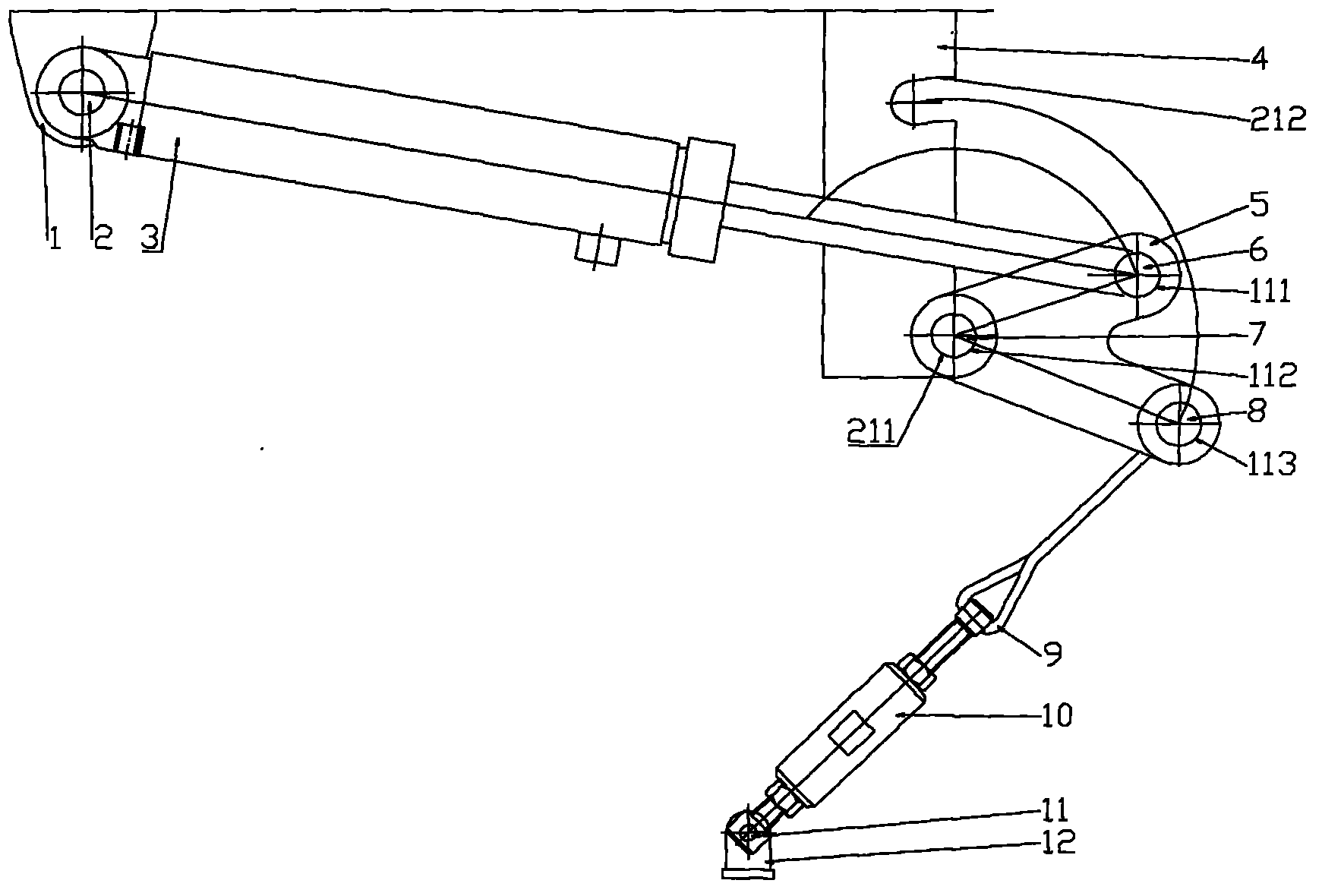

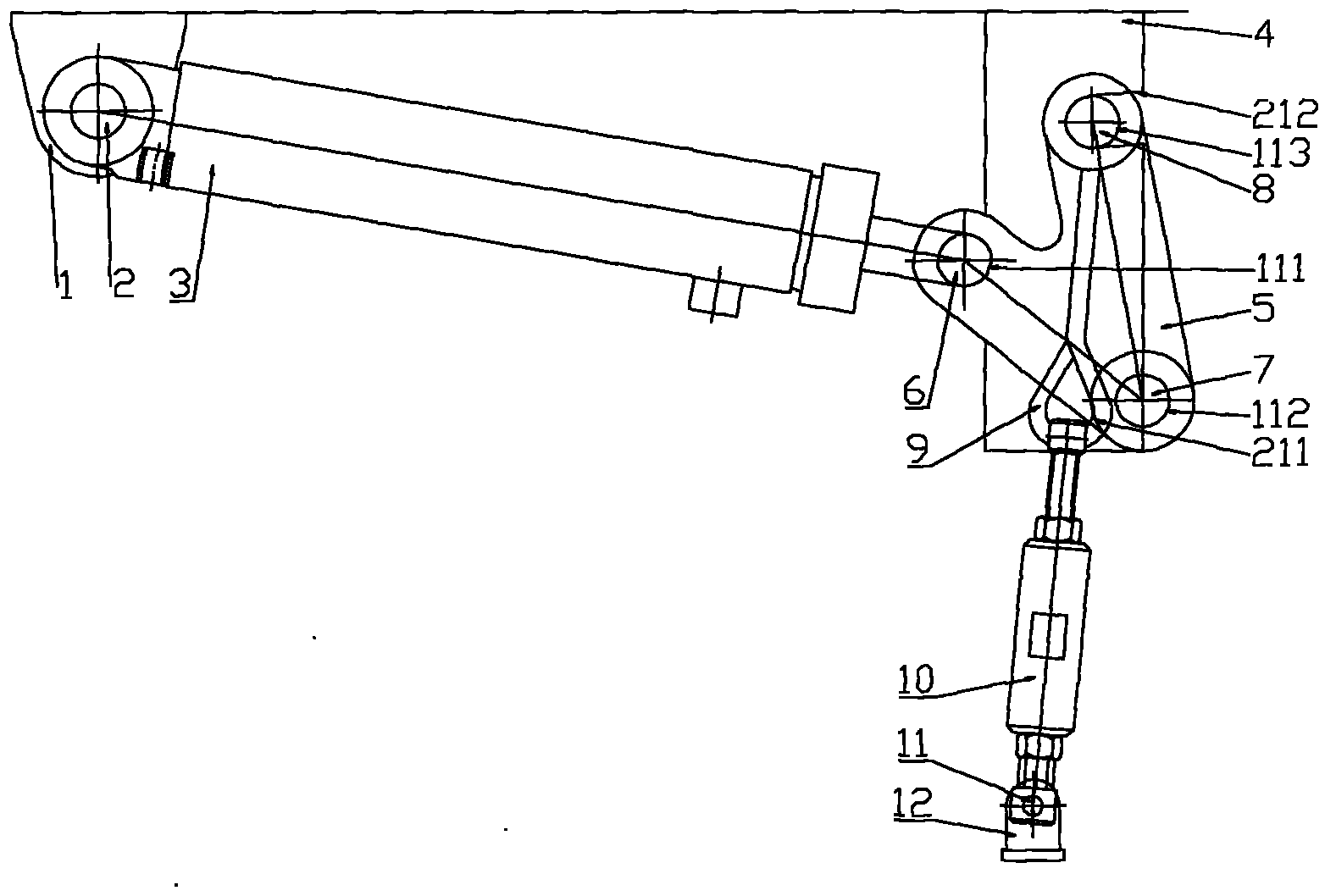

[0011] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

[0012] As shown in the figure, a vacuum nozzle lifting self-locking device includes an oil cylinder support 1, a lifting cylinder 3, a crank arm support 4, a three-hole crank arm 5, a steel rope 9, a length adjustment rod 10, and a pin shaft 2. , pin two 6, pin three 7, pin four 8, pin five 11, one end of the length adjustment rod 10 is connected to the steel rope 9, and the other end is connected to the dust suction nozzle assembly through the pin five 11 The seat 12 is hinged, and the length adjustment rod 10 can be adjusted and locked. The three-hole crank arm 5 is placed between the lifting cylinder 3 and the steel rope 9, and the hole 111 of the three-hole crank arm 5 is connected to the post of the lifting cylinder 3. The plug end is hinged by the pin two 6, the hole 113 and the steel rope 9 are hinged by the pin four 8, the tail end of the lifting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com