Patents

Literature

80results about How to "Affect normal driving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Voltage equilibrium control method and system

ActiveCN104527448AVoltage balanceEasy to operate and flexibleElectric devicesVehicular energy storageCapacitanceEngineering

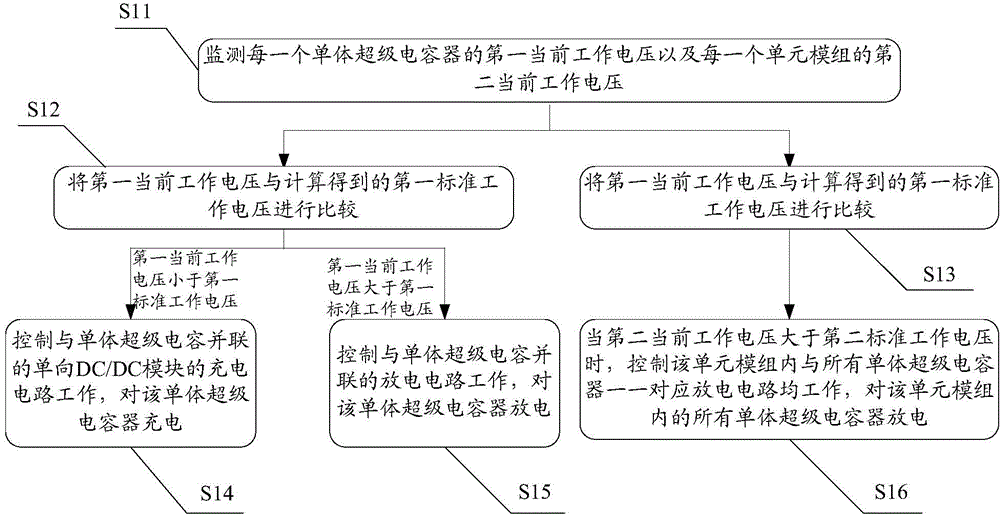

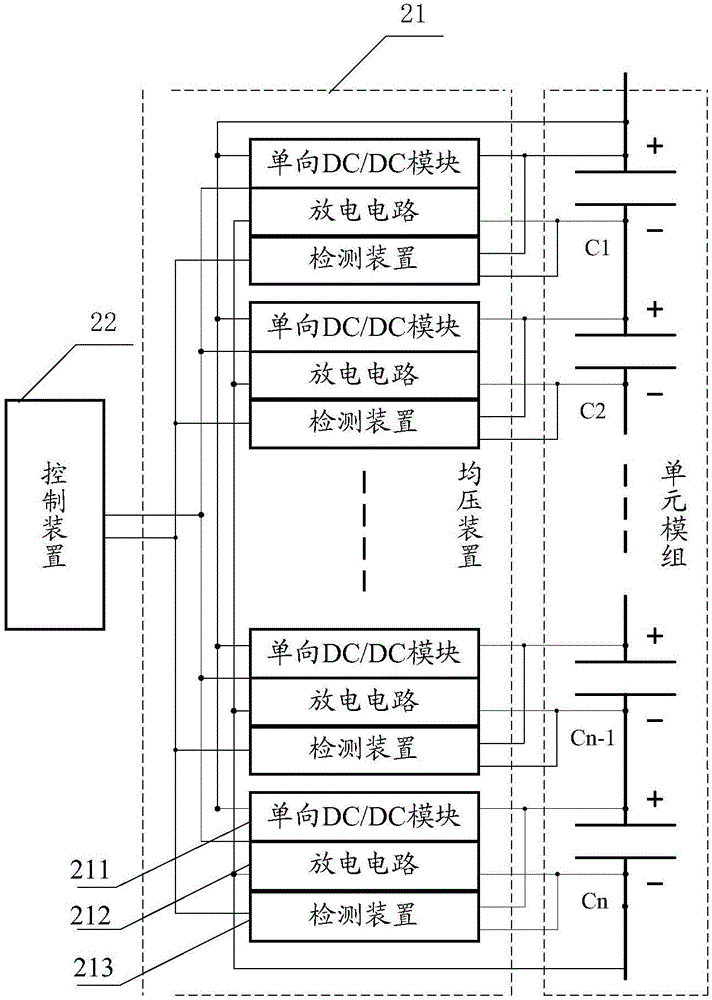

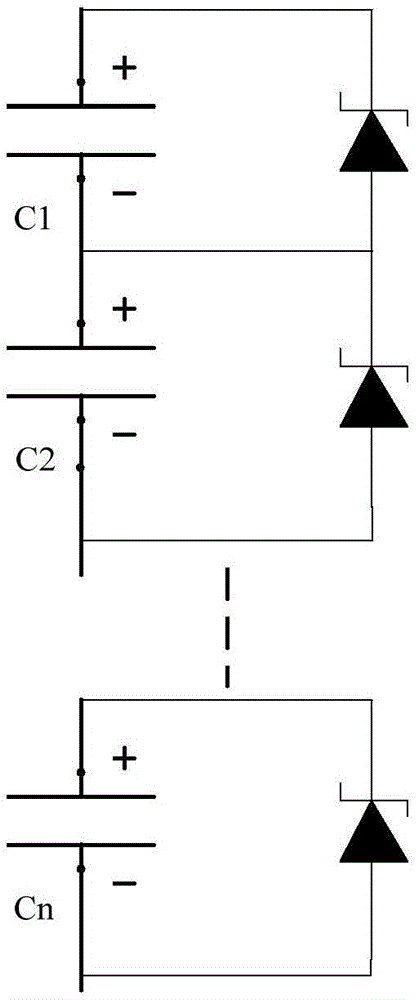

The invention provides a voltage equilibrium control method and system which are applied to an energy storing device composed of a plurality of unit modules. Each unit module comprises at least two single supercapacitors, the first current working voltage of each single supercapacitor and the second current working voltage of each unit module are monitored and compared with corresponding standard working voltages, so that when it is determined that the first current working voltage is smaller than the first standard working voltage, a charging circuit of a one-way DC / DC module connected with the corresponding single supercapacitor in parallel is controlled to work so as to charge the corresponding single supercapacitor; otherwise, a discharging circuit connected with the corresponding single supercapacitor in parallel is controlled to work so as to discharge the corresponding single supercapacitor; operation is convenient, flexible and high in reliability, the single supercapacitors in the energy storing device are prevented from being permanently damaged due to overcharge and over discharge, and safe and reliable operation of an energy storing type urban rail transit vehicle is guaranteed.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Intelligent vehicle starting operation assistant system and control method thereof

PendingCN109177966AKnow the characteristics of driving habitsAffect normal drivingDriver/operatorVehicle control

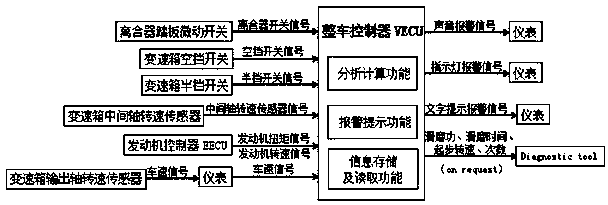

The invention discloses an intelligent vehicle starting operation assistant system and a control method thereof. The system comprises a vehicle controller VECU, an engine controller EECU, an instrument, a transmission output shaft rotational speed sensor, a transmission intermediate shaft rotational speed sensor, a clutch pedal micro switch, a transmission neutral gear switch, a transmission half-gear switch and an accelerator pedal. The method comprises the following steps: 1, the vehicle controller VECU judges when the vehicle is in the starting state; 2, the VECU of the whole vehicle control monitors the instantaneous slip wear energy of the clutch in real time, accumulates the slip wear energy, the slip wear time, the starting speed and the real-time gear information of the transmission, estimates the wear percentage of the clutch plate, and simultaneously starts to record the information relate to the starting operation of all the vehicles; and 3, that the vehicle exits from the vehicle starting operation assistant system. The intelligent vehicle starting operation assistant system enables the driver to start the vehicle through more standardized operation, improves the probability of the successful start of the vehicle, and greatly prolongs the service life of the clutch plate.

Owner:DONGFENG COMML VEHICLE CO LTD

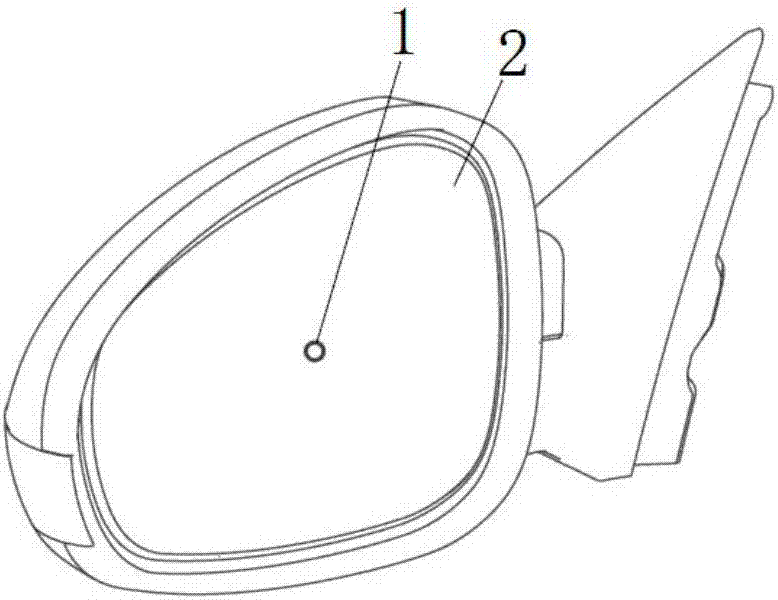

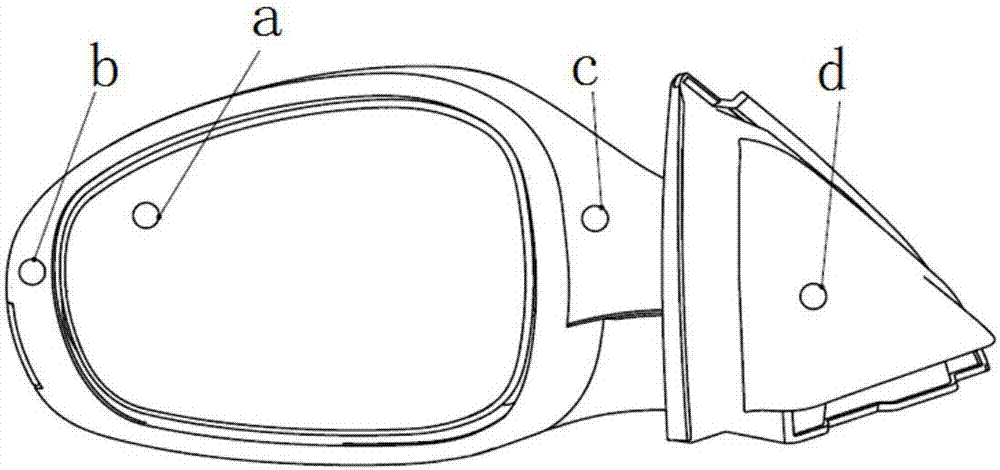

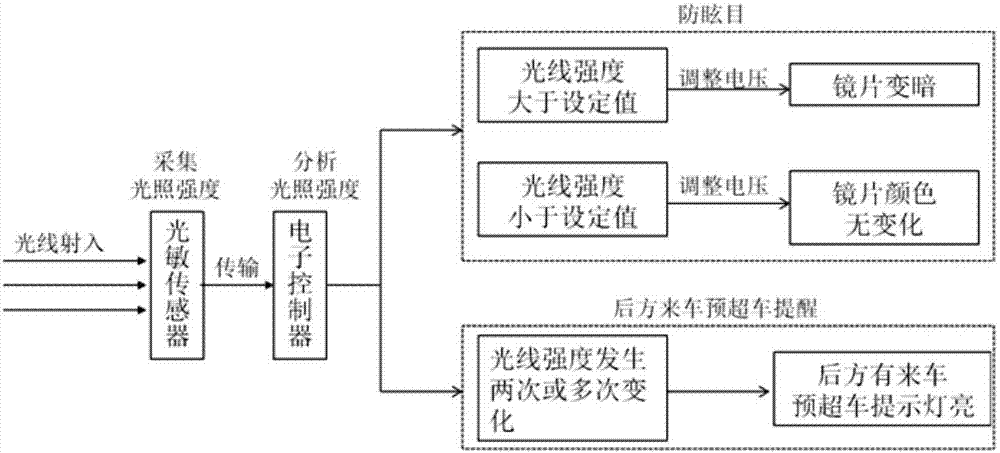

Automatic anti-dazzling outer rearview mirror, anti-dazzling control method and vehicle coming reminding method

InactiveCN107310480AAffect normal drivingImprove safety incidentsOptical viewingElectronic controllerOptoelectronics

The invention discloses an automatic anti-dazzling outer rearview mirror. The automatic anti-dazzling outer rearview mirror comprises a rearview mirror lens, and further comprises a connected electronic controller and a photosensitive sensor used for inducting the light intensity; the rearview mirror lens is a conductive photochrommic lens; the photosensitive sensor is arranged on the rearview mirror lens which comprises a conductive layer; and the conductive layer is connected with the electronic controller. The rearview mirror can change the color of the lens according to the intensity of lamplight of a rear vehicle, the intensity of light reflected into the eyes of a driver is adjusted, and it is avoided that the lamplight of the rear vehicle affects normal driving of a front driver; and the driver can be reminded about pre-lane-changing and overtaking of the rear vehicle, and makes judgment in advance, so that the safety accident caused by negligence of the driver can be avoided.

Owner:CHERY AUTOMOBILE CO LTD

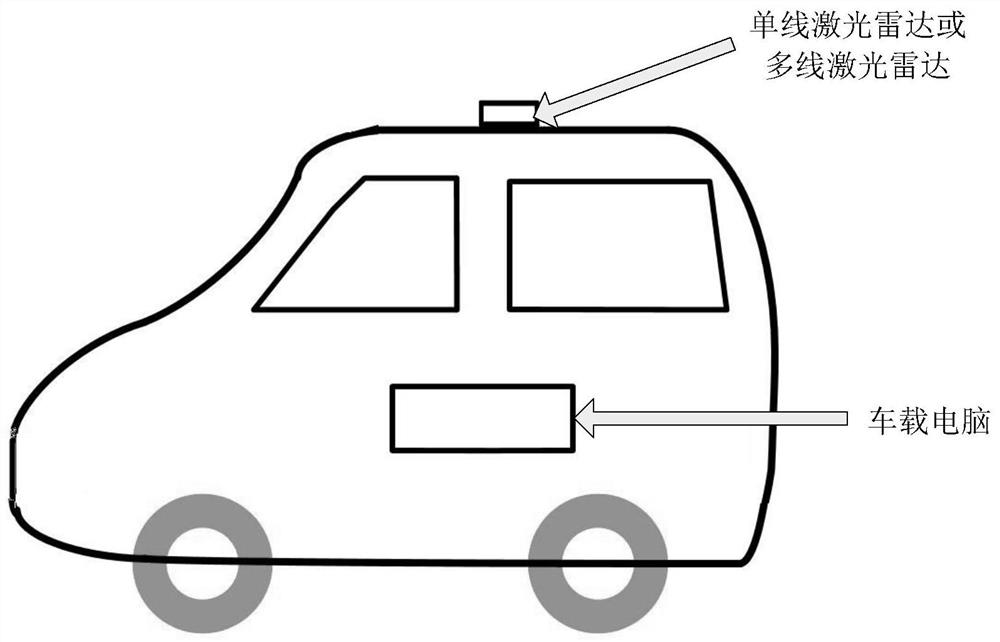

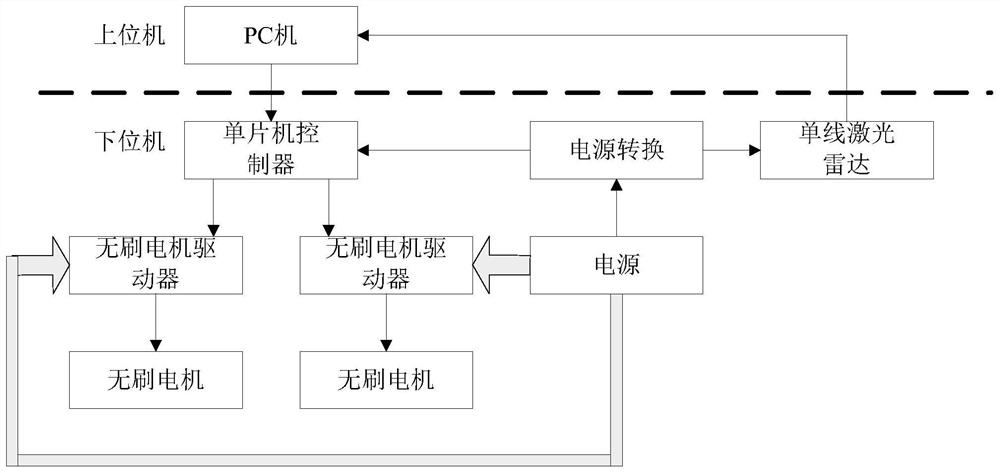

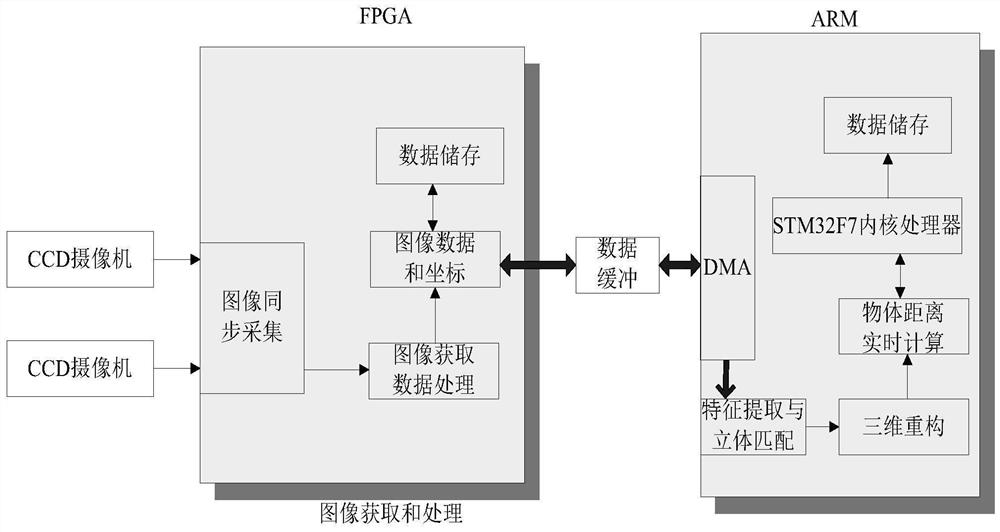

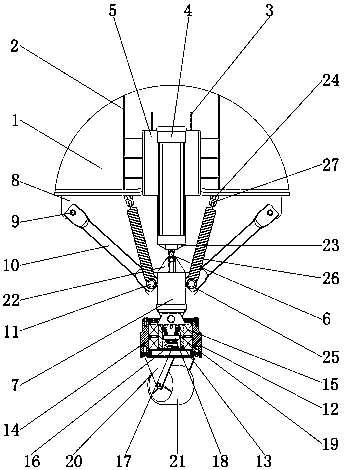

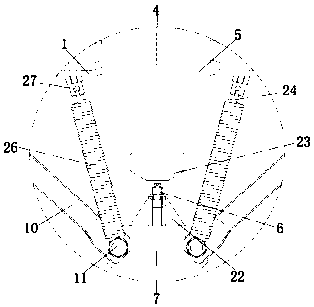

Multi-sensor fused unmanned vehicle detection obstacle avoidance system and obstacle avoidance method

PendingCN112180941ASolve slow running bottlenecksEasy to controlPosition/course control in two dimensionsVehiclesControl signalSimulation

The invention provides a multi-sensor fused unmanned vehicle detection obstacle avoidance system and obstacle avoidance method. The obstacle avoidance system comprises a plurality of single-line laserradars, double CCD cameras, microwave radars, front and rear blind area ultrasonic sensor groups and a three-core controller based on ARM + FPGA + NUC. A plurality of single-line laser radar signalsare processed by the NUC microcomputer, binocular vision graphic data of the CCD camera are jointly processed by the ARM + FPGA controller, functions of blind area detection and obstacle avoidance, ahuman-computer interface, path planning, online output and the like are independently completed by the STM32F767, and the ARM + FPGA controller outputs control signals through decoding to accurately control the direct-current brushless servo motor, and drives an unmanned vehicle to run. According to the invention, the unmanned vehicle can discover obstacles in a complex environment in an all-weather and farther manner and quickly realize effective obstacle avoidance, so the safety and stability of the unmanned vehicle during high-speed driving are improved.

Owner:LEITON FUTURE RES INSTITUTION JIANGSU CO LTD +2

Automobile rollover prevention device

The invention discloses an automobile rollover prevention device comprising an automobile body. Brackets are mounted on the left side and the right side of the automobile body, racks are arranged in the brackets, the brackets are connected with the racks, and an air cylinder is arranged outside the racks and is electrically connected with the automobile body; and a jacking rod is mounted at the bottom of the air cylinder, a fixing block is mounted at the bottom of the jacking rod, second rotating rods are mounted on the left side and the right side of the fixing block correspondingly, and supporting rods are connected to the exteriors of the second rotating rods in a sleeving mode. According to the automobile rollover prevention device, through cooperation of the supporting rods, the fixing block and the jacking rod, under the effect of a buffering piece, the supporting rods and the fixing block are mutually connected and move along with rotating of the jacking rod, thus the stabilityof the fixing block is improved, and the service life of the fixing block is prolonged; and under the effect of idler wheels, the two sides of the automobile body can be supported through the idler wheels, the unfolding area of the automobile body is decreased, the safety of the automobile body is improved, and the automobile rollover prevention device is suitable for being used and popularized.

Owner:NANJING LISHUI HIGH-TECH VENTURE CAPITAL MANAGEMENT CO LTD

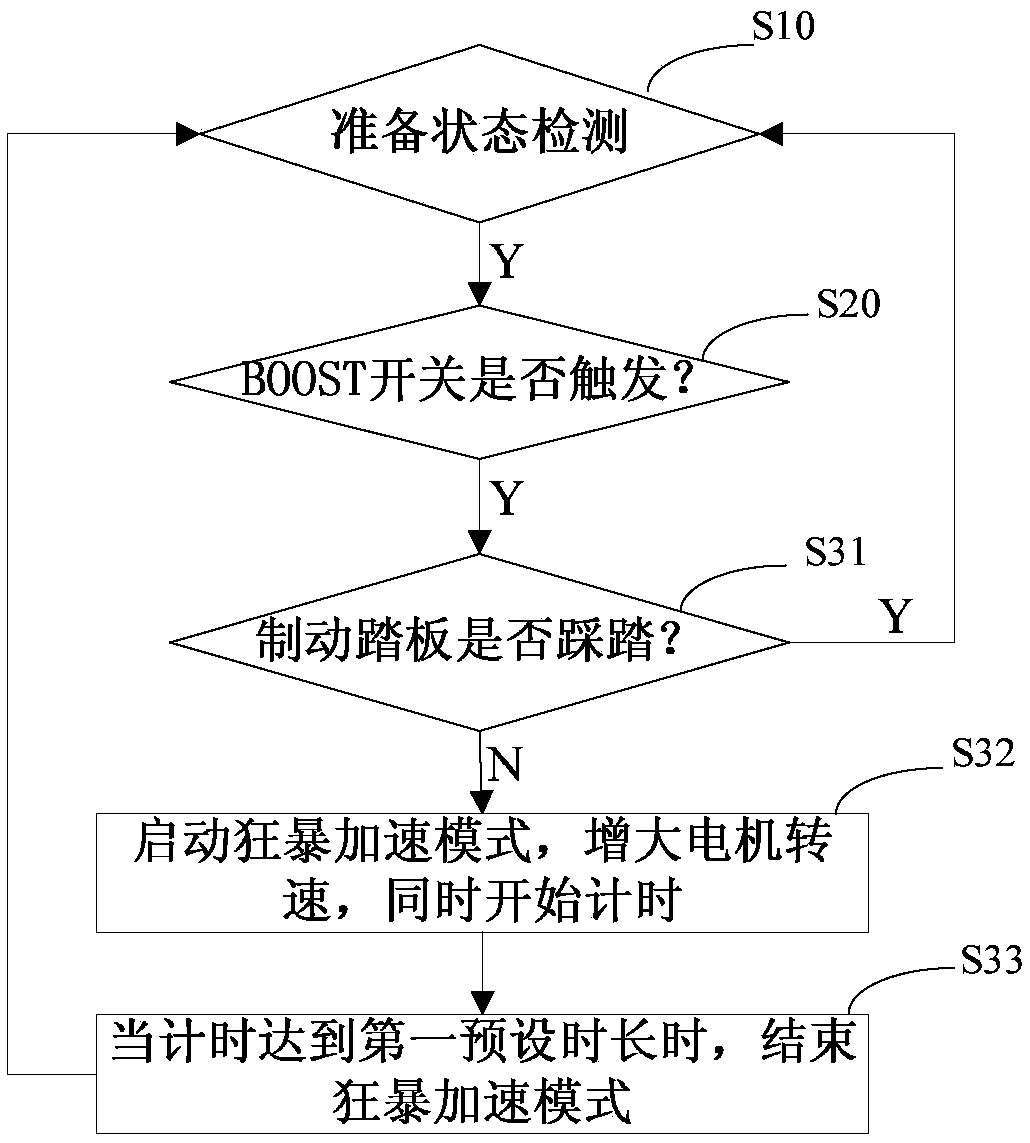

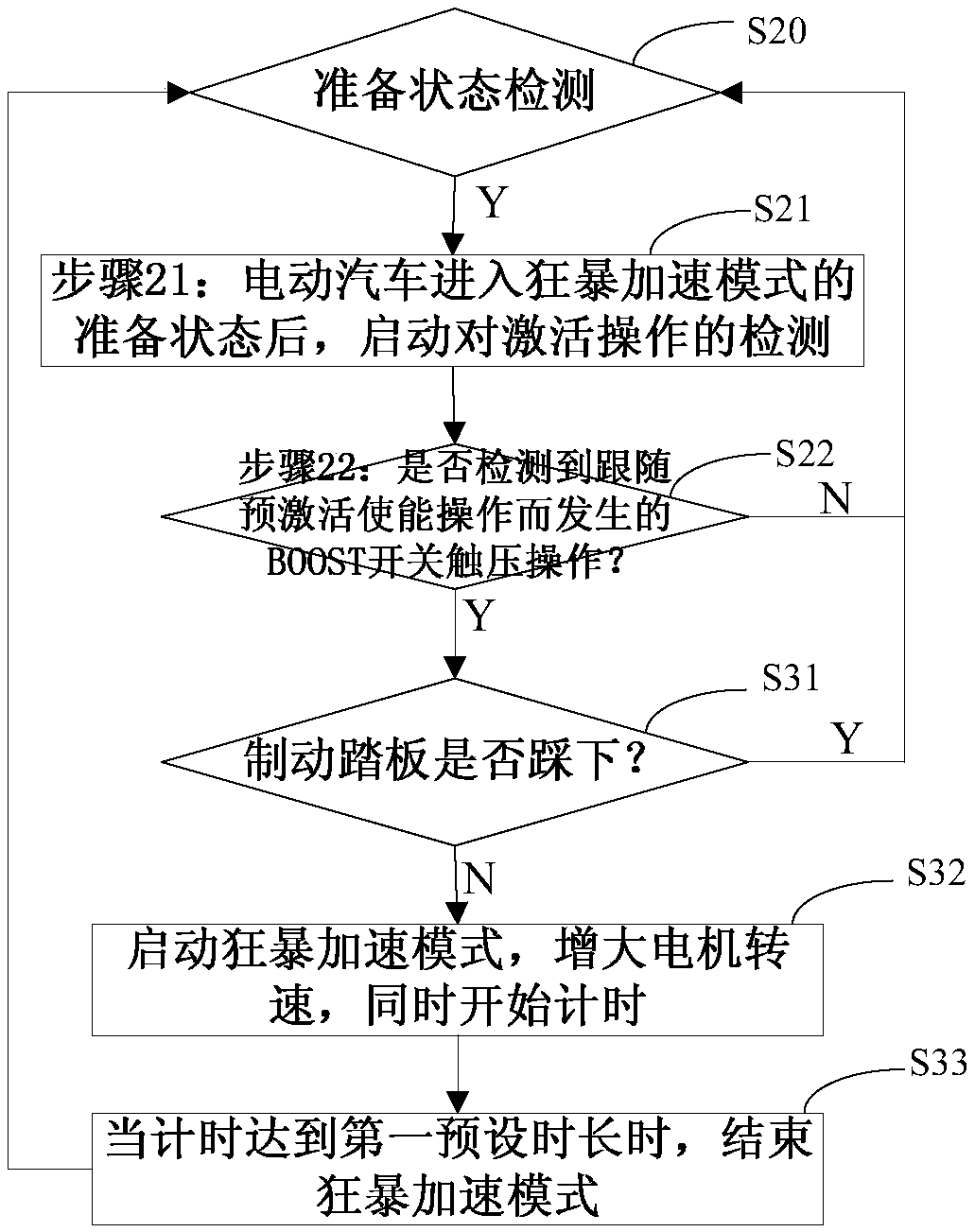

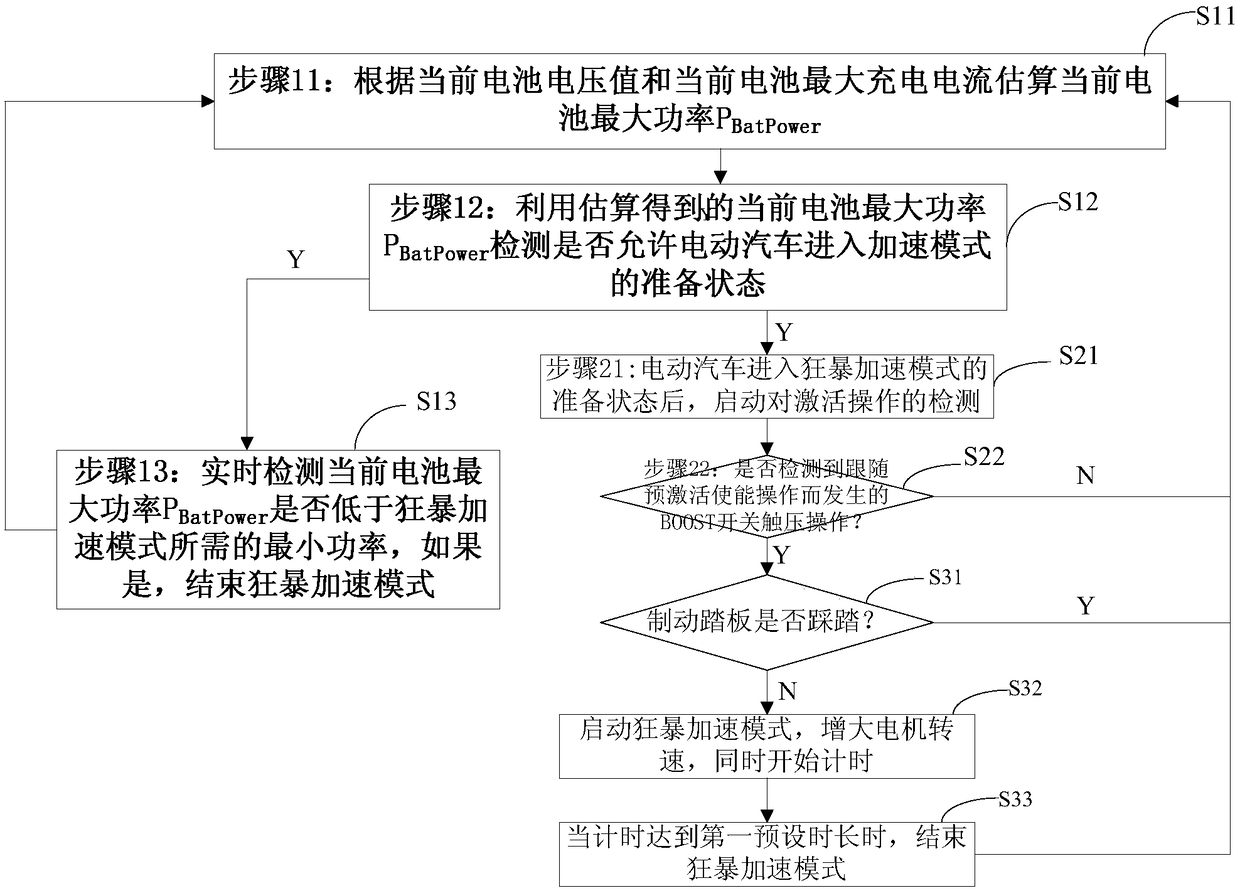

Ludicrous accelerating mode control method, storage medium and electric automobile

InactiveCN108773297AAffect normal drivingSpeed controllerElectric energy managementMode controlBiological activation

The invention provides a ludicrous accelerating mode control method, a storage medium and an electric automobile. The ludicrous accelerating mode control method comprises the steps of step 21, starting detection to activation operation after the electric automobile enters a preparing state of a ludicrous accelerating mode; and step 22, when detecting that the pressing operation of a BOOST switch generated by following pre-activation enabling operation, entering an activated state of the ludicrous accelerating mode. According to the ludicrous accelerating mode control method, the storage mediumand the electric automobile, the existing BOOST switch activation is improved as an activation program including at least two operation information; the improved activation program can guarantee thatthe ludicrous accelerating mode can only be activated when a driver is intended to experience; and the driver can be effectively prevented from starting the ludicrous accelerating mode due to false operation to affect the normal driving.

Owner:CH AUTO TECH CORP CO LTD

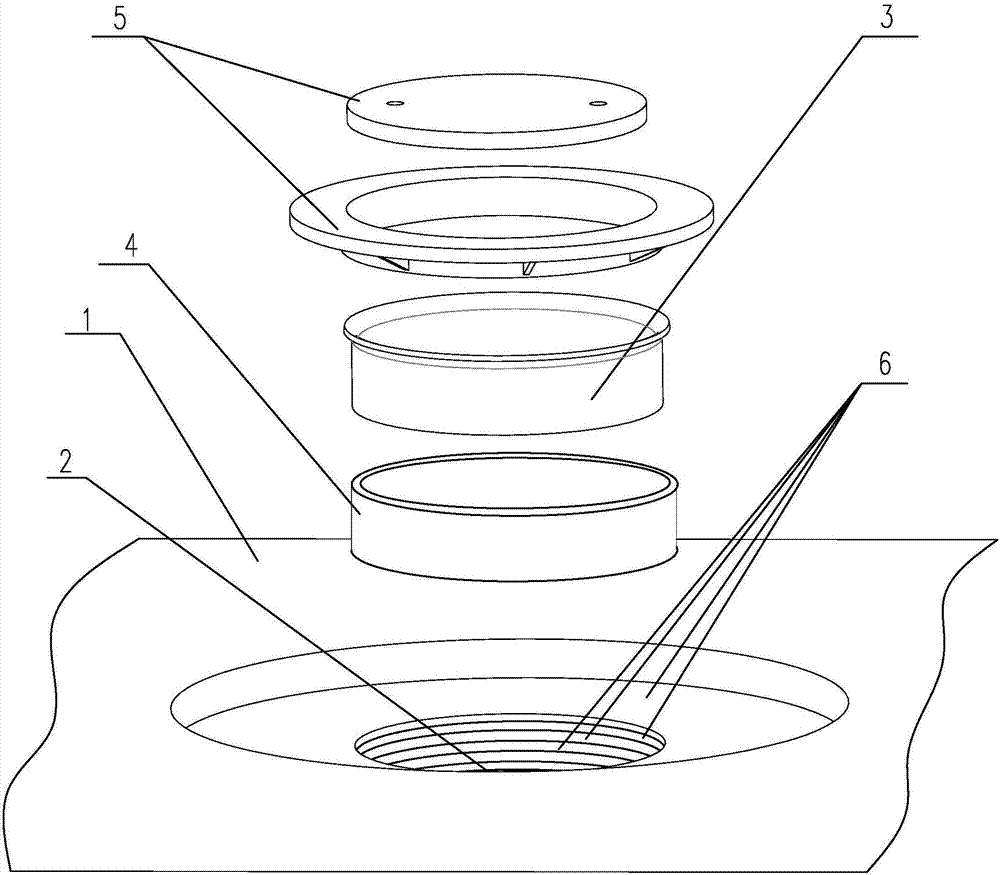

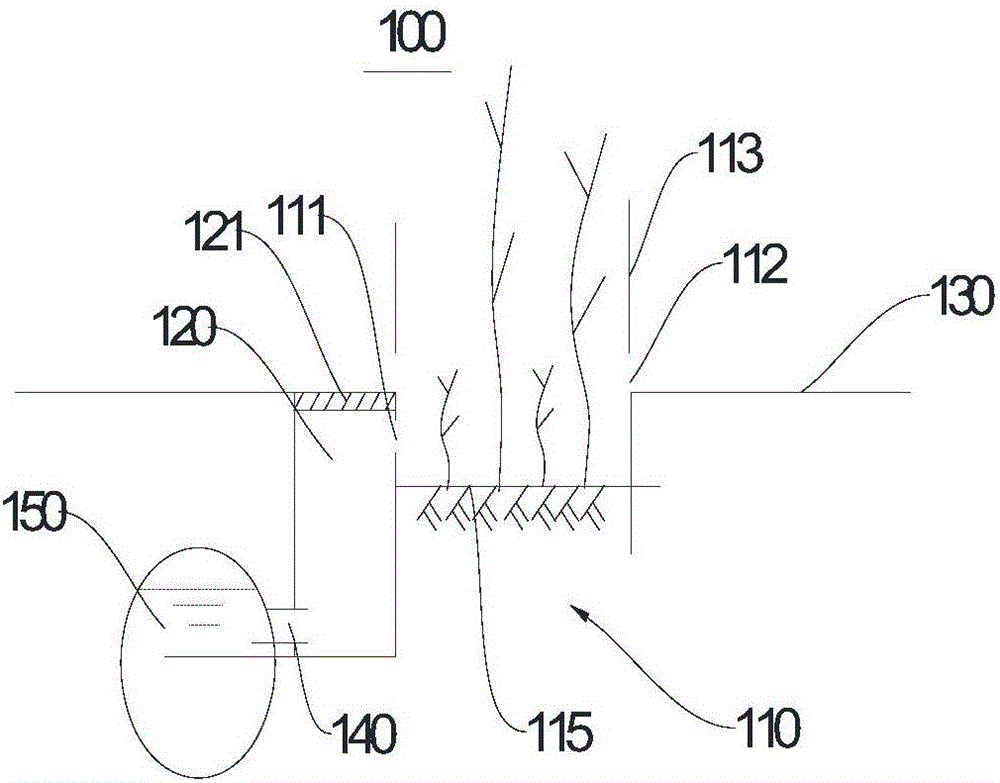

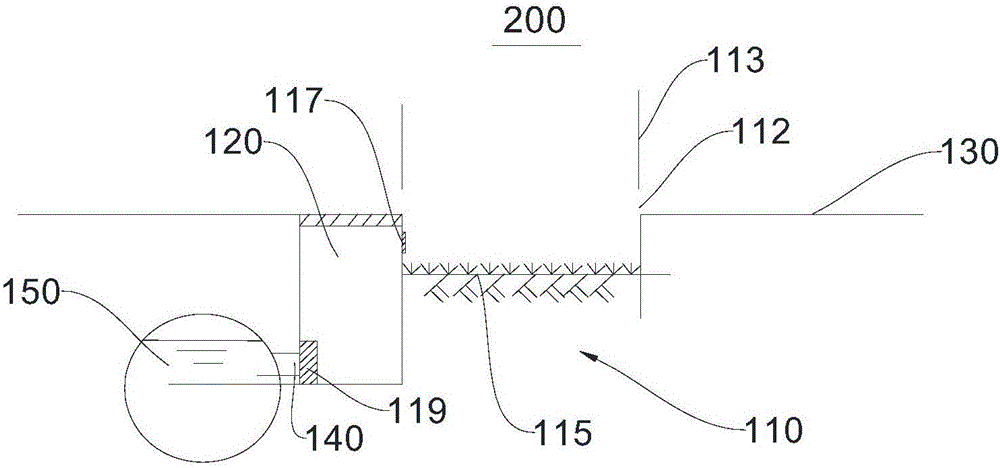

Well lid construction installation method

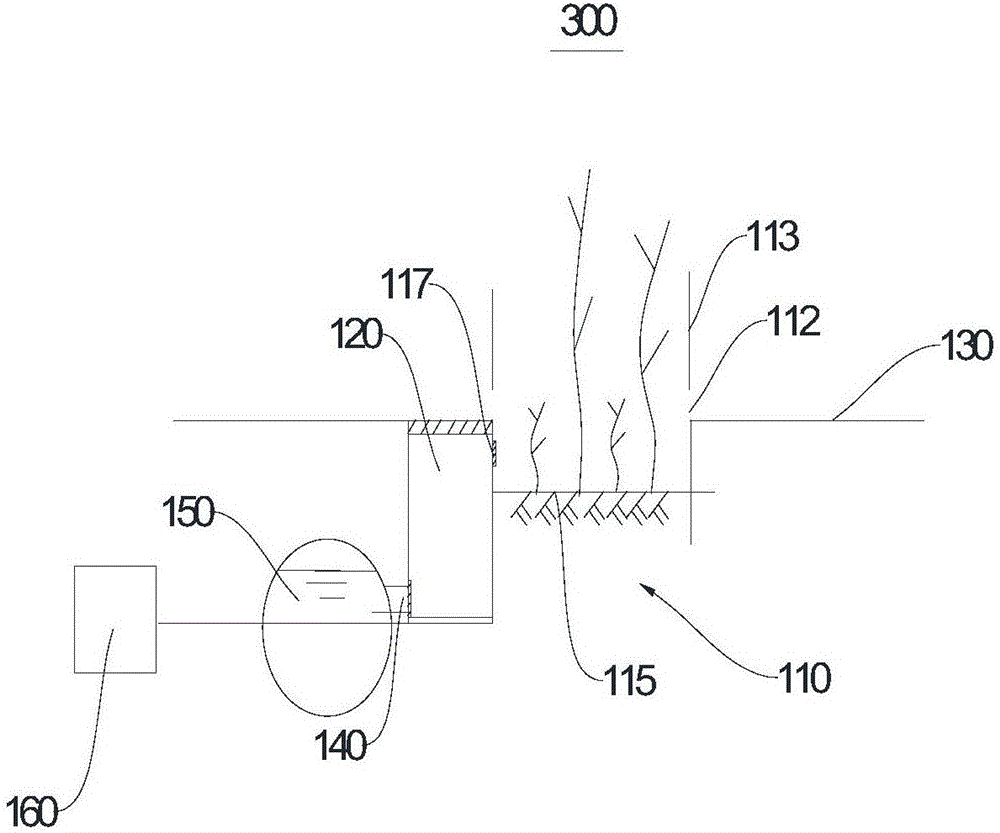

ActiveCN106930327AConvenience to workAvoid damageArtificial islandsUnderwater structuresArchitectural engineeringRoad surface

The invention discloses a well lid construction installation method. The method includes the following steps that the pavement exploding range is determined, and exploding is conducted; a cast iron limiting shaft is installed; filling and compacting of asphalt concrete are conducted; and finally, a well lid is installed. By means of the well lid construction installation method, the construction quality can be ensured, the construction time is short, efficiency is high, in addition, the well lid is pressed into the pavement and is integrated with the pavement, and the levelness is consistent.

Owner:WENZHOU MUNICIPAL CONSTR & DEV

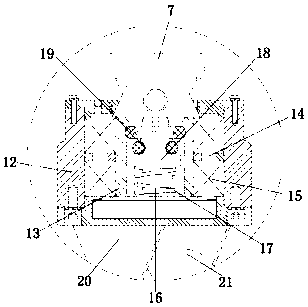

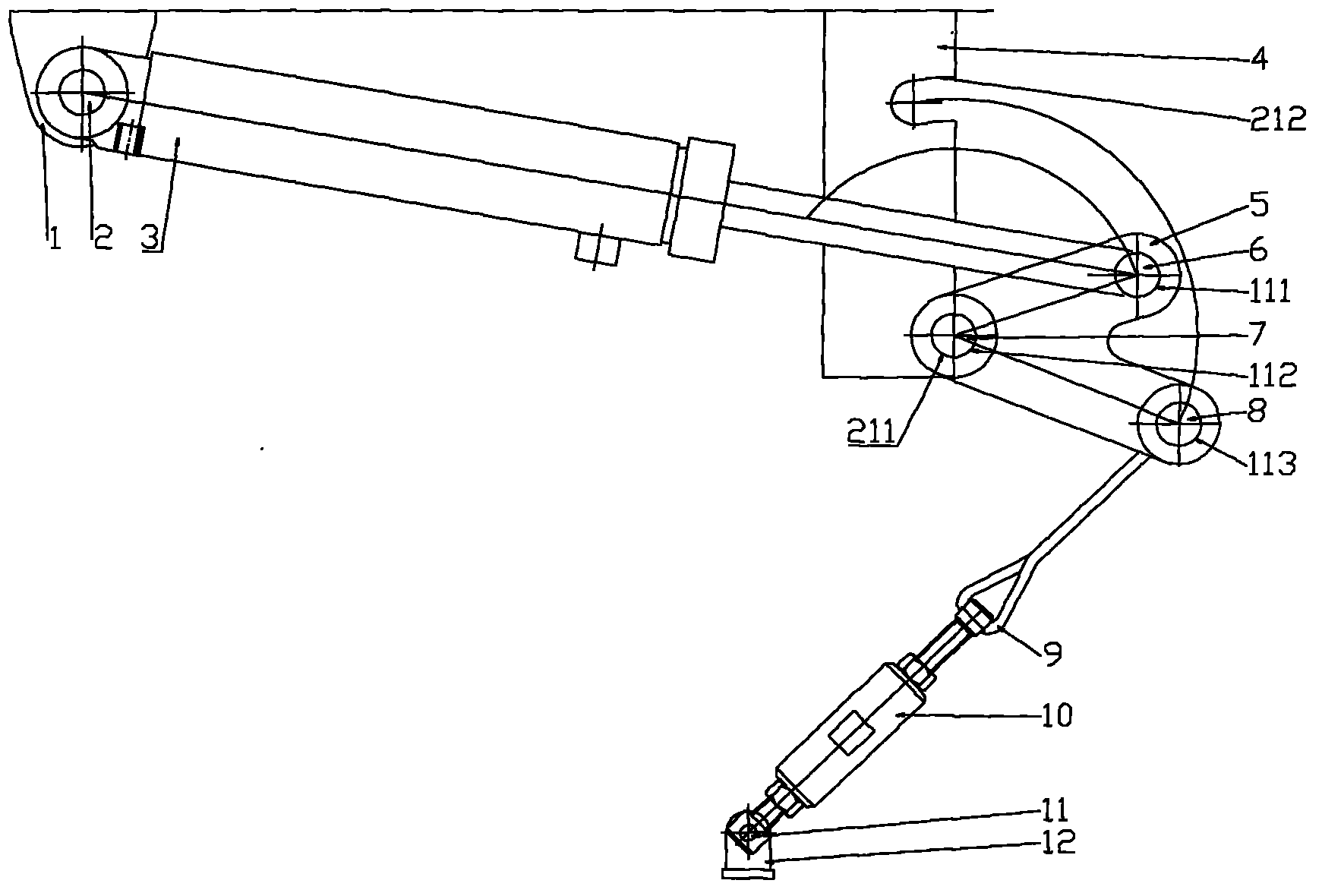

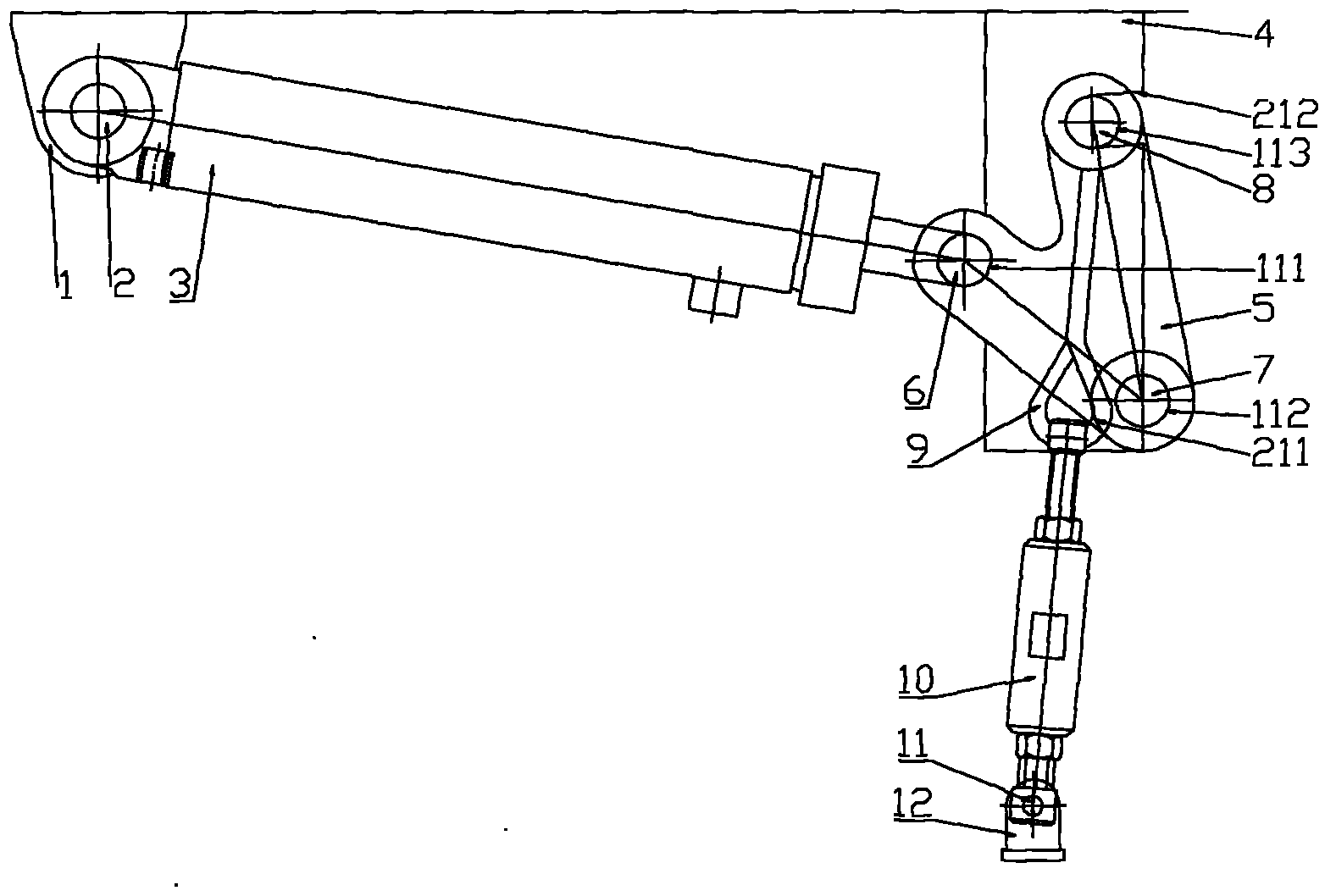

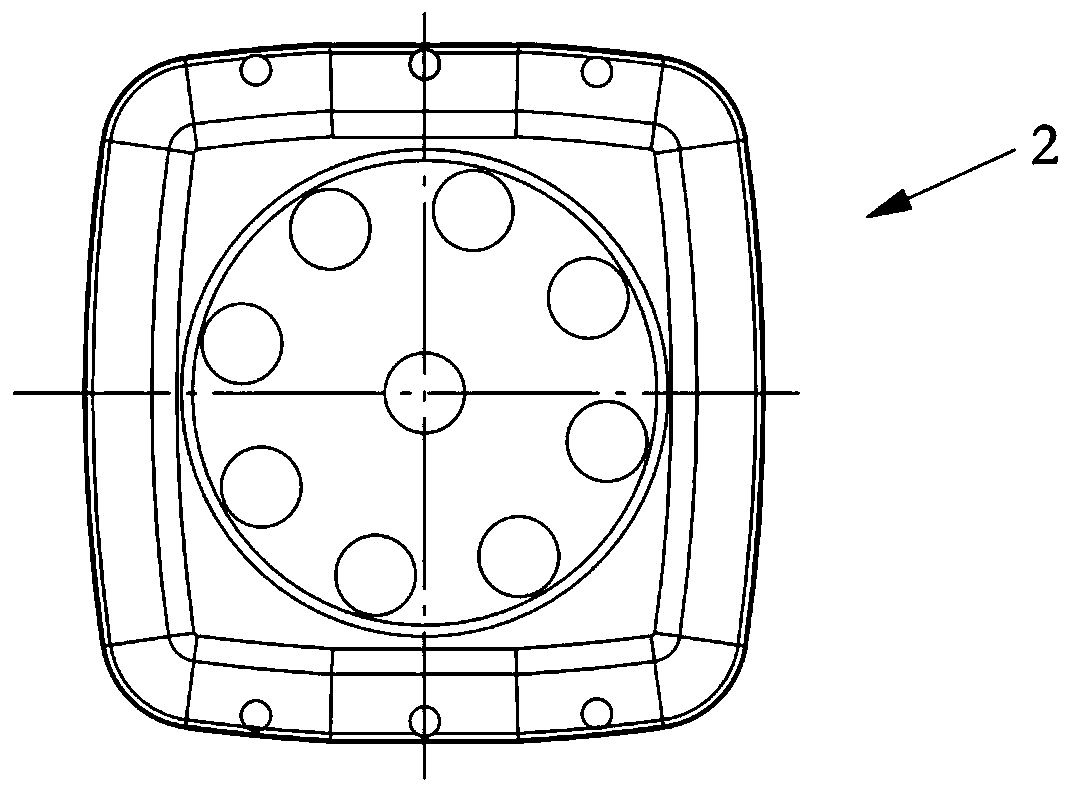

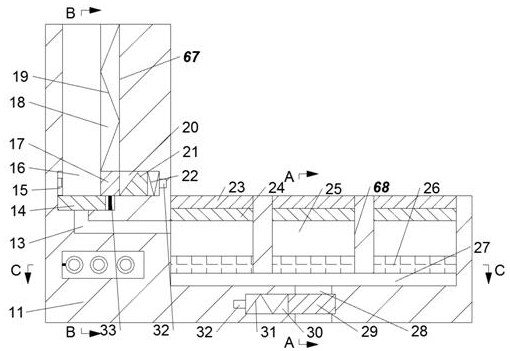

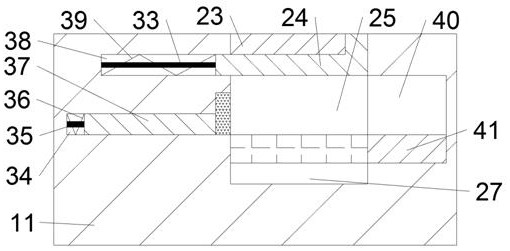

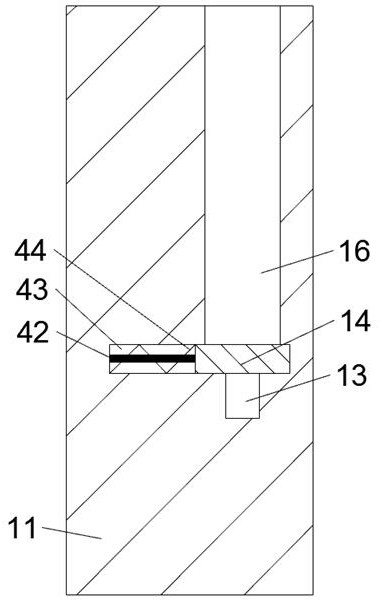

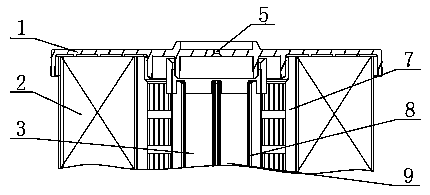

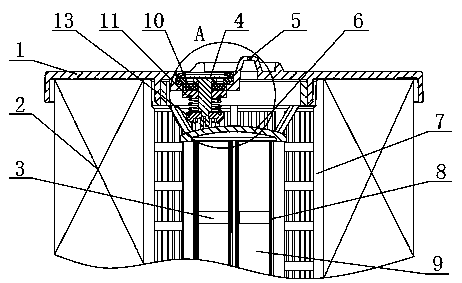

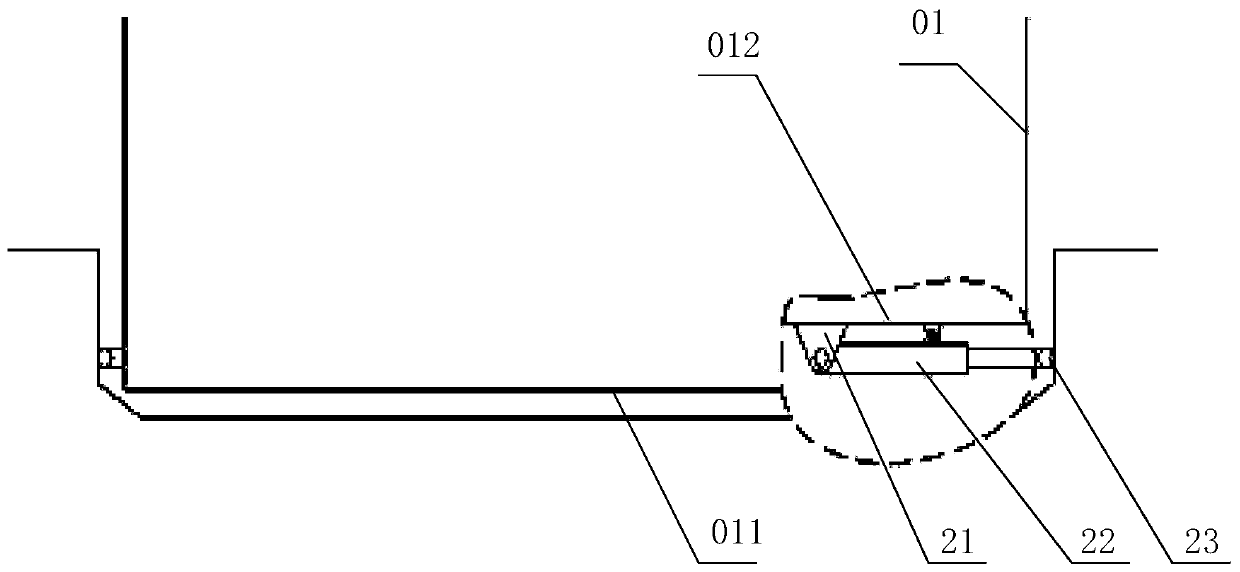

Dust suction nozzle lifting self-locking device

The invention relates to a dust suction nozzle lifting self-locking device, which mainly solves the problems that dust suction nozzle assemblies of the existing various sweeping vehicles cannot be completely locked after being lifted by a hydraulic oil cylinder and a steel rope, and the normal running of the sweeping vehicles is influenced caused by the slow falling of a dust suction nozzle because of vibration, inner leakage of a hydraulic system and the like in the running process of the sweeping vehicles. The dust suction nozzle lifting self-locking device is formed by combining a lifting oil cylinder, an oil cylinder support seat, a three-hole crank arm, a crank arm support seat, a steel rope, a length regulating rod and a pin shaft, wherein one end of the length regulating rod is connected with the steel rope, the other end of the length regulating rod is hinged with a connecting support seat of a dust suction nozzle assembly by a pin shaft, the three-hole crank arm is arranged between the lifting oil cylinder and the steel rope and is hinged with the lifting oil cylinder and the steel rope through the pin shaft, the three-hole crank arm is hinged with a crank arm support seat hole through the pin shaft to form a fixed rotary center, and a circular arc groove facing the lifting rotation direction of the three-hole crank arm is formed at the upper end of the crank arm support seat. When the lifting oil cylinder pulls the three-hole crank arm to upwards rotate, the steel rope is connected with the pin shaft to enter the circular arc groove and goes around the rotary center of the crank arm support seat, the dust suction nozzle realizes the self locking through the self-weight forming force moment, and the influence on the normal running of the sweeping vehicles caused by descending and dropping of the dust suction nozzle cannot be generated. When the dust suction nozzle needs to descend for sweeping work, only an oil cylinder is required for pushing the three-hole crank arm to downwards rotate.

Owner:WENZHOU POLYTECHNIC

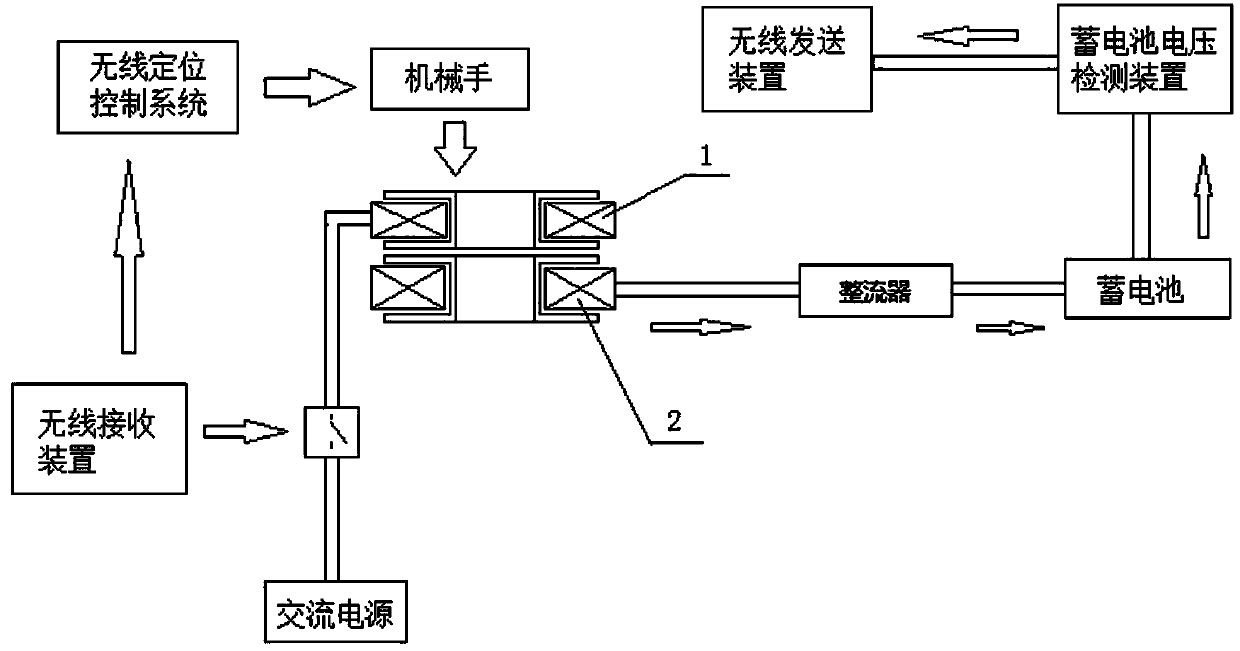

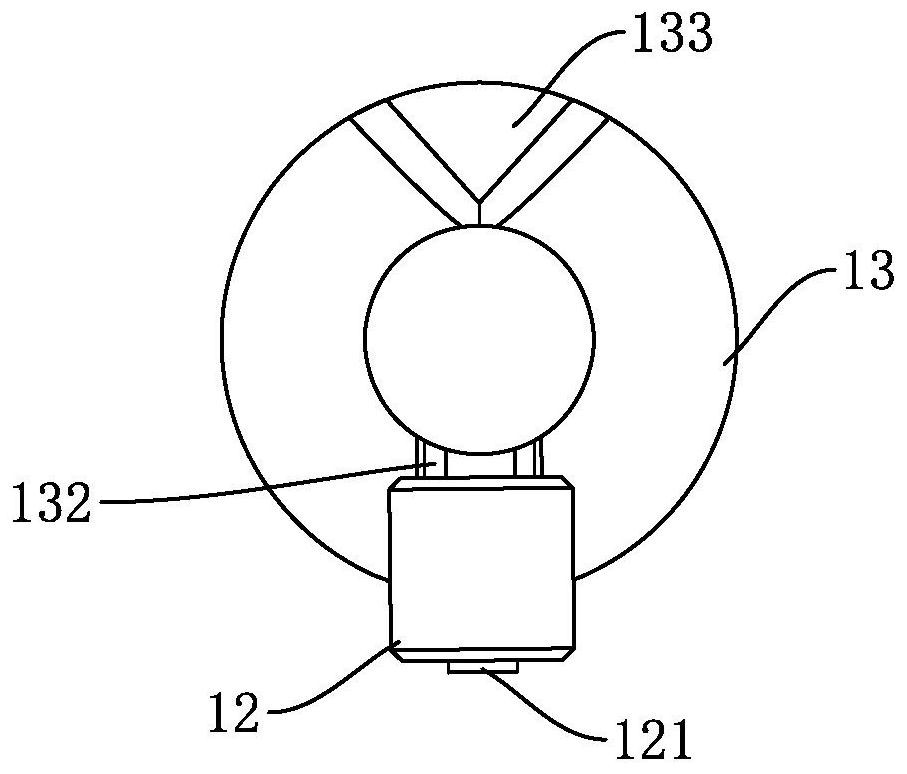

Automatic wireless charging method for electric automobile and complete device

InactiveCN103427464AAffect normal drivingRealize automatic chargingBatteries circuit arrangementsElectromagnetic wave systemControl systemManipulator

The invention discloses an automatic wireless charging method for an electric automobile and a complete device implementing the method. The complete device comprises a charging end component and an automobile end component, the charging end component comprises a wireless positioning control system, a manipulator, a primary electromagnetic mutual inductance coil and a wireless receiving device, the wireless positioning control system controls action of the manipulator, the primary electromagnetic mutual inductance coil is mounted on a mechanical arm, the wireless receiving device controls the wireless positioning control system and a charging line switch of the charging end component, the automobile end component comprises a storage battery voltage detection device, a wireless transmitting device, a secondary electromagnetic mutual inductance coil and a rectifier, output of the storage battery voltage detection device is connected with the wireless transmitting device, and an output end of the secondary electromagnetic mutual inductance coil is connected with the rectifier. The complete device has an automatic charging function, a public charging system is set up by the aid of the complete device, and unattended operation can be realized.

Owner:黄建东

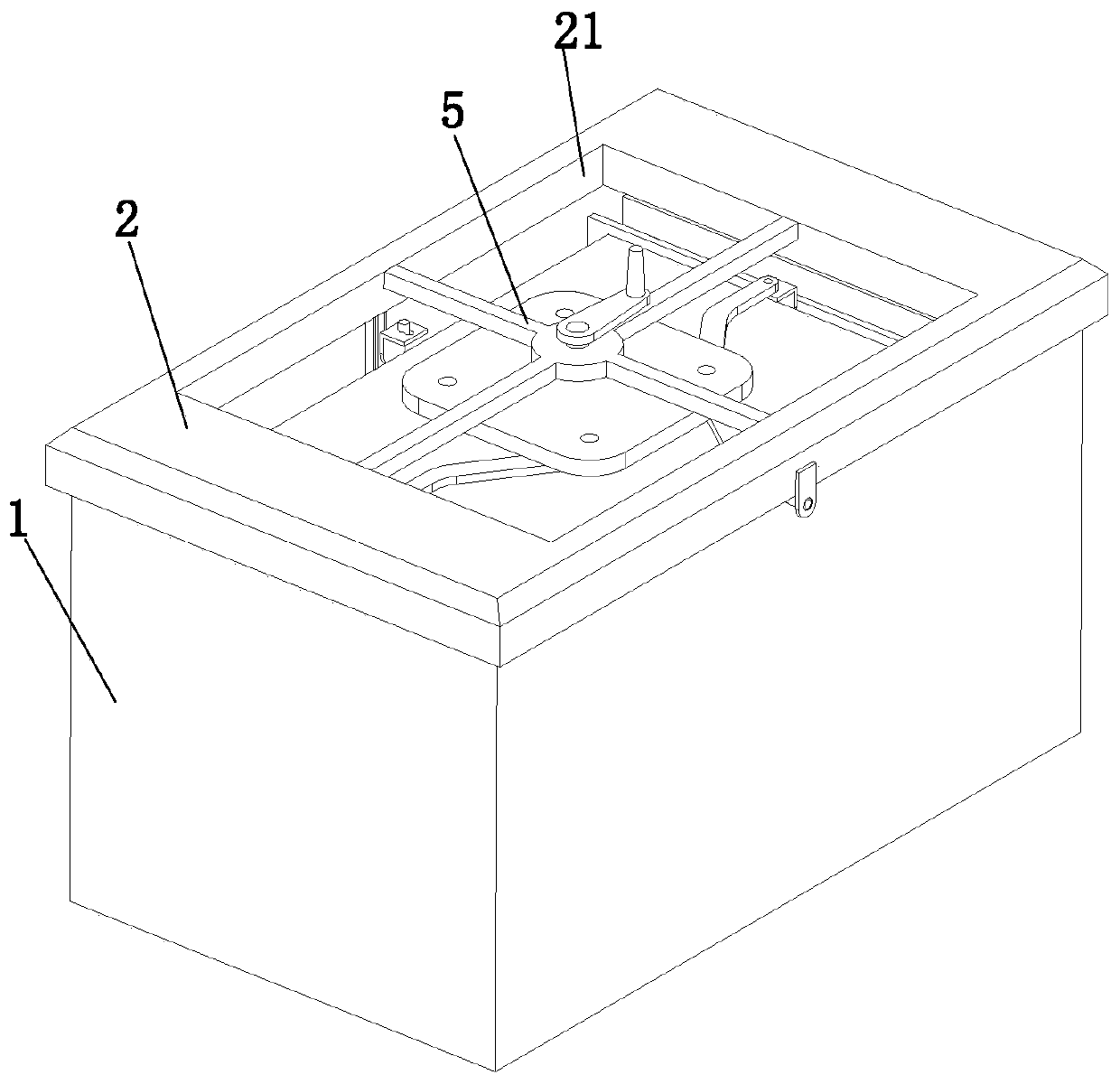

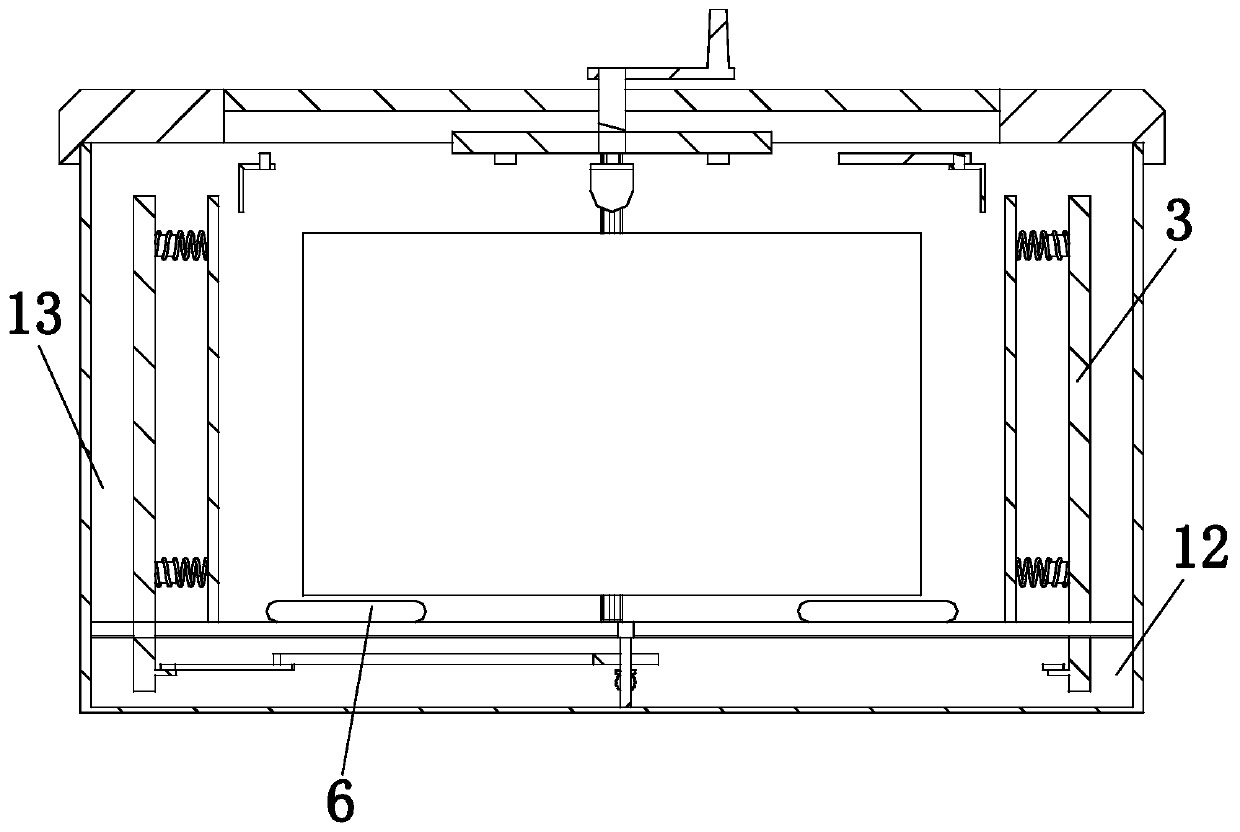

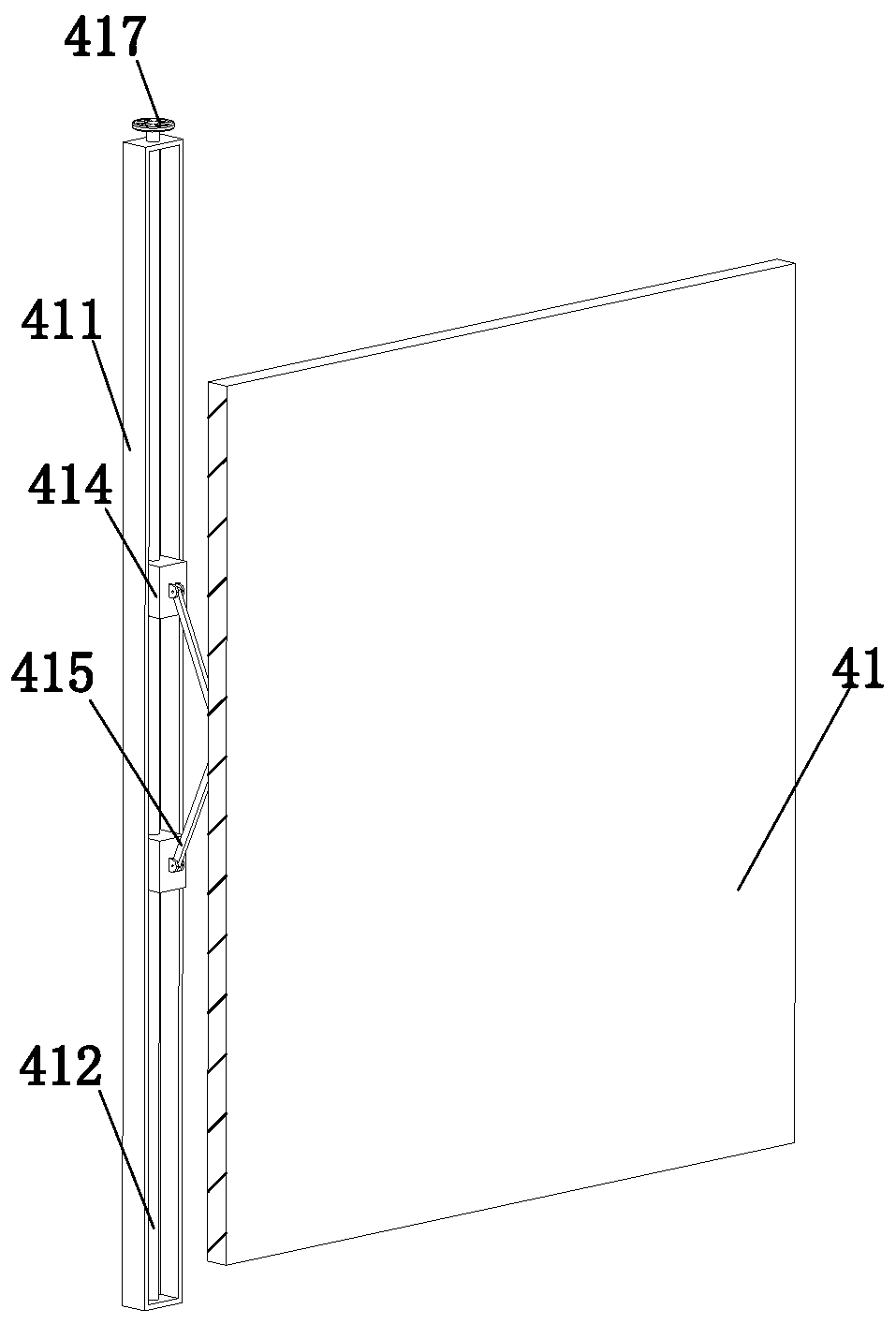

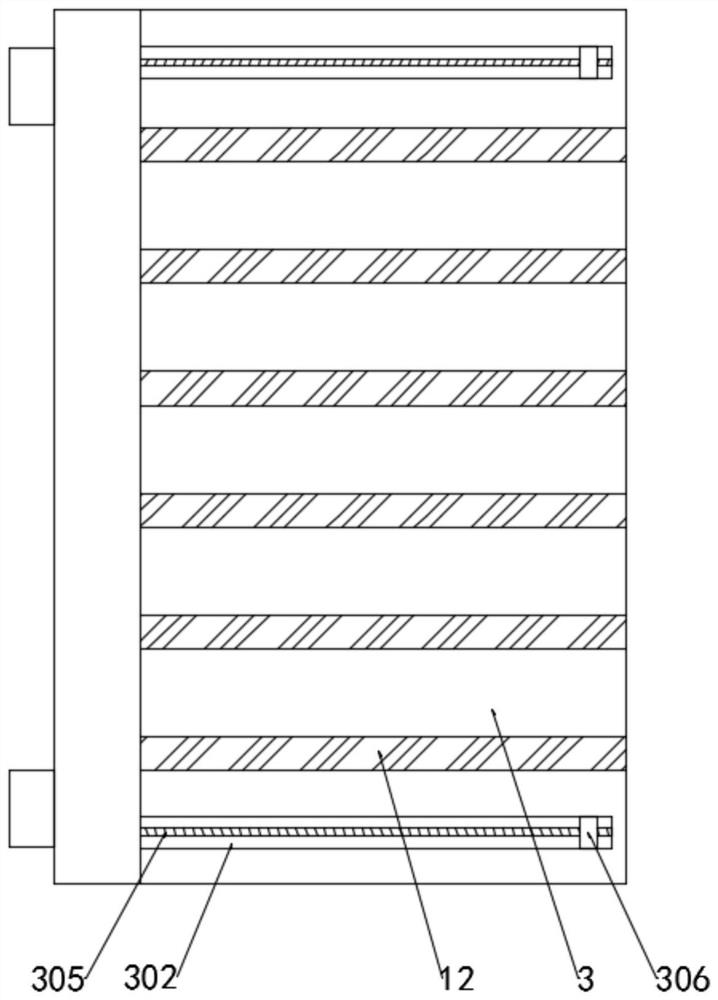

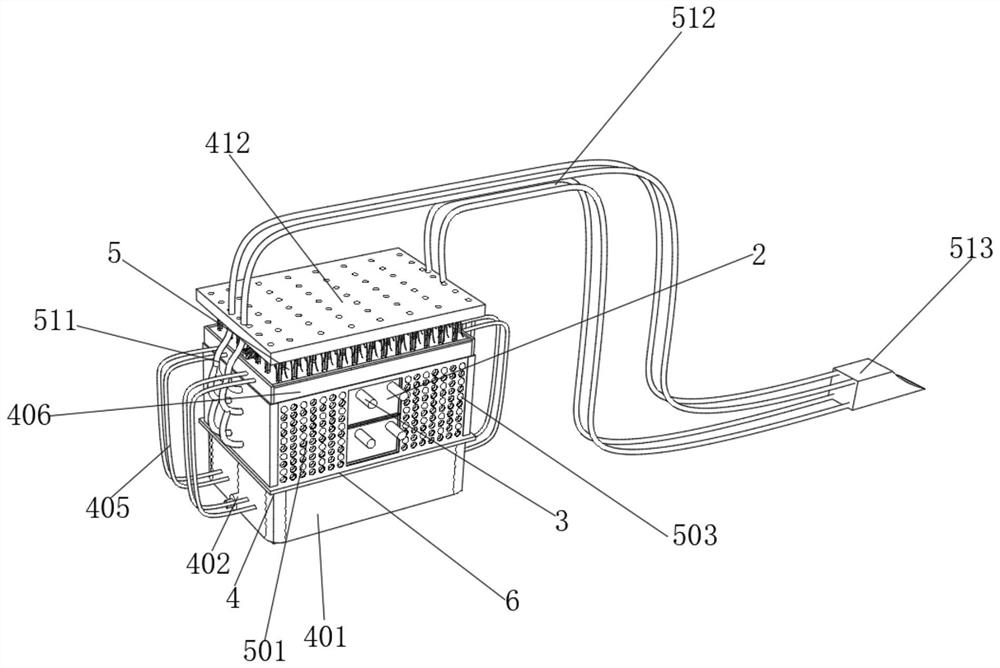

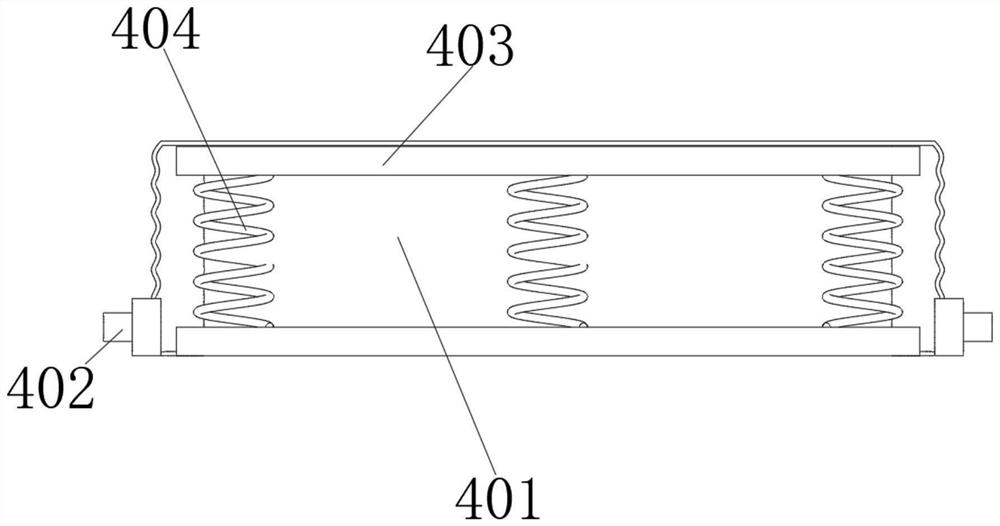

Battery buffer device for new energy vehicles

InactiveCN110335976AAffect normal drivingAvoid influenceElectric propulsion mountingCell component detailsNew energyElectrical battery

The invention discloses a battery buffer device for new energy vehicles, belonging to the technical field of new energy vehicles. The battery buffer device for new energy vehicles comprises a batterystorage box, an opening and closing box cover, a first fixing assembly, a second fixing assembly and a third fixing assembly. The battery storage box is provided with a partition board, which dividesthe battery storage box into a first accommodating cavity and a second accommodating cavity. The opening and closing box cover is arranged on a side wall of the battery storage box. The first fixing assembly is arranged in the first accommodating cavity, and the moving end of the first fixing assembly is in sliding fit with the partition board. The second fixing assembly is arranged on a side wallof the second accommodating cavity. The opening and closing box cover is provided with a mounting slot in the top, and the third fixing assembly is arranged on the mounting slot of the opening and closing box cover. After a battery pack is fixed in all directions by the first fixing assembly, the second fixing assembly and the third fixing assembly, the battery pack can be prevented from being affected by the huge shaking of a vehicle during driving.

Owner:HEFEI CAREER TECHNICAL COLLEGE

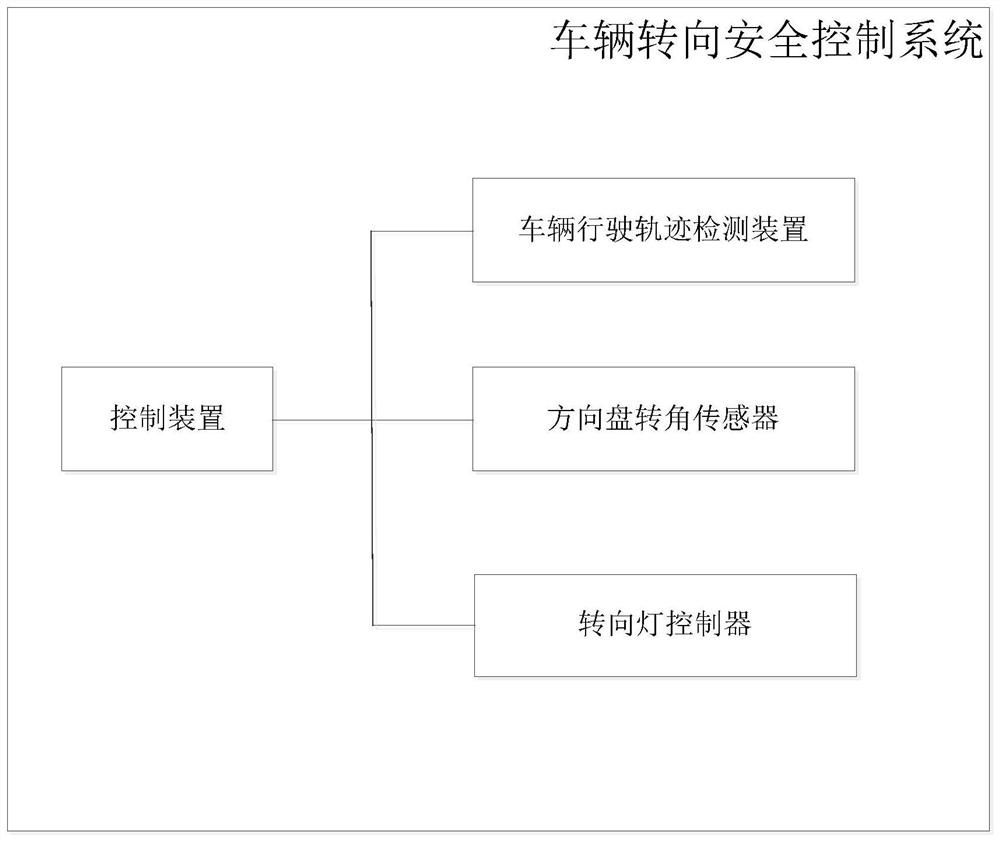

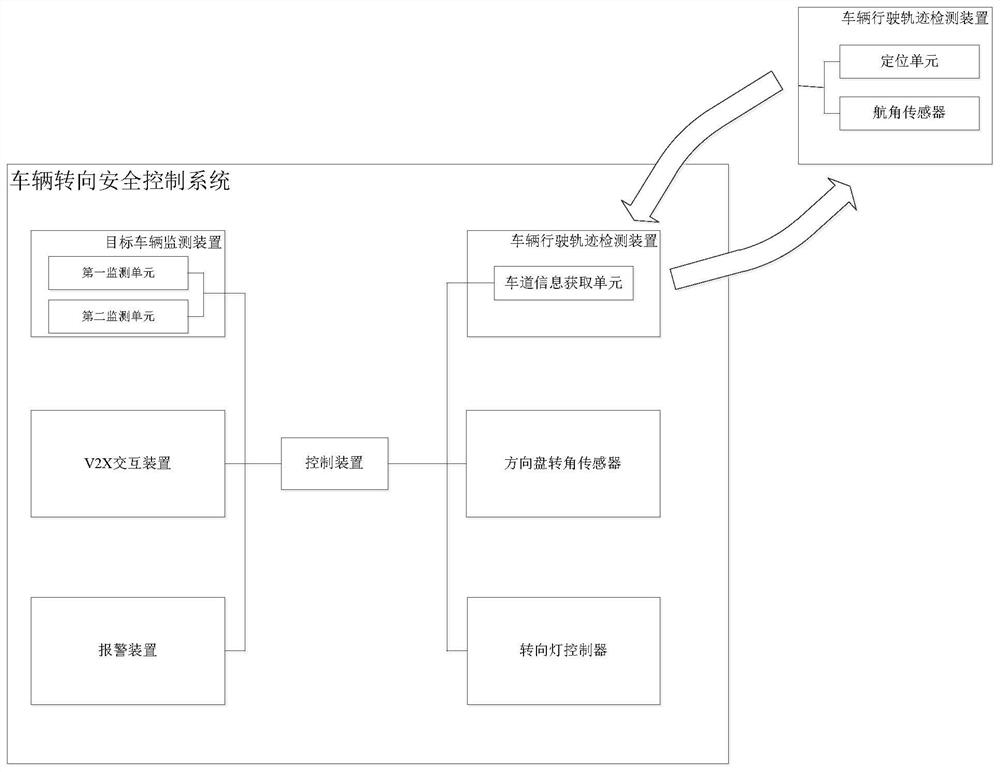

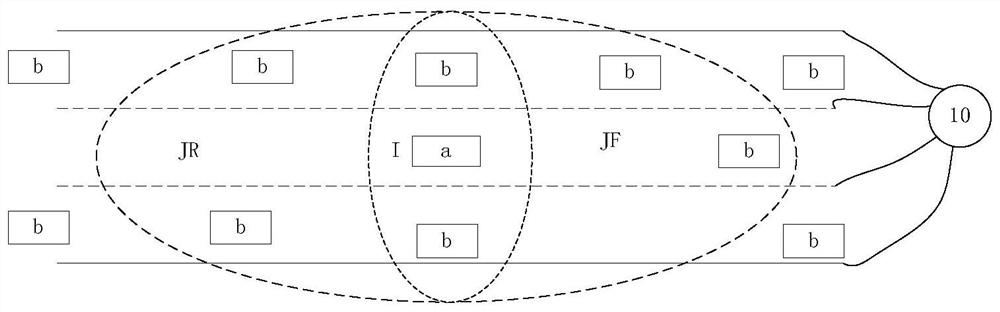

Vehicle steering safety control system and vehicle

PendingCN111746383AAvoid the problem of forgetting to turn on the turn signalRealize self-controlled opening controlOptical signallingSteering wheelDriver/operator

The invention relates to the field of vehicle safety steering, and provides a vehicle steering safety control system and a vehicle. The invention relates to a vehicle steering safety control system, which comprises a vehicle driving track detection device used for detecting the real-time driving track of the vehicle, a steering wheel angle sensor which is used for detecting real-time angle information of the steering wheel; a control device which is used for judging whether an included angle exists between the running direction of the vehicle and a lane line or not according to the real-time running track, and sending a corresponding steering warning instruction under the condition that the included angle exists between the running direction of the vehicle and the lane line and the real-time turning angle of the steering wheel is larger than a first threshold value; and a steering lamp controller which is used for receiving the corresponding steering warning instruction sent by the control device and turning on the corresponding steering lamp according to the corresponding steering warning instruction, so that the problem that the normal driving of the vehicle or the adjacent vehicle is influenced when a driver forgets to turn on the steering lamp during lane changing can be avoided, and the safety of lane changing behaviors is improved.

Owner:GREAT WALL MOTOR CO LTD

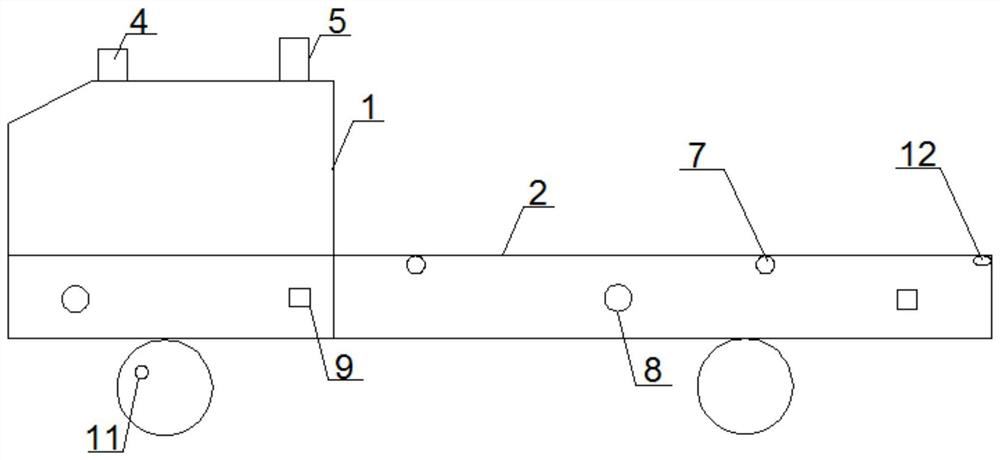

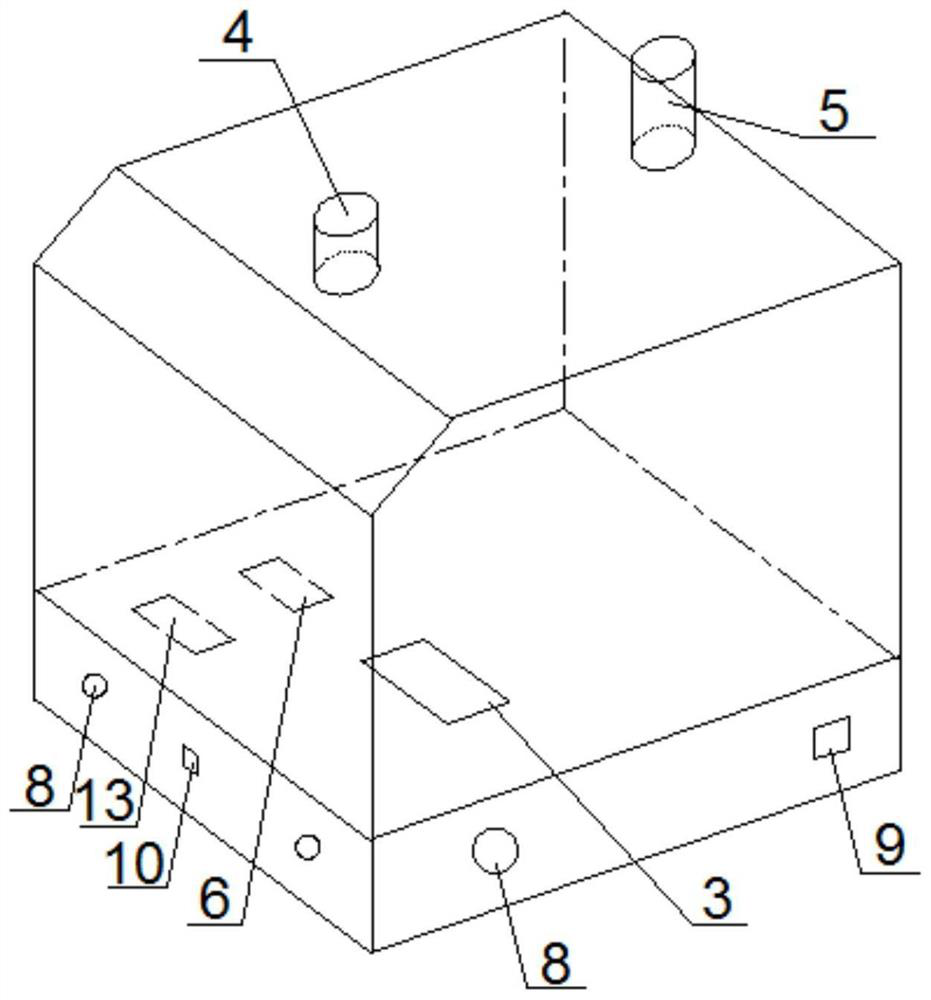

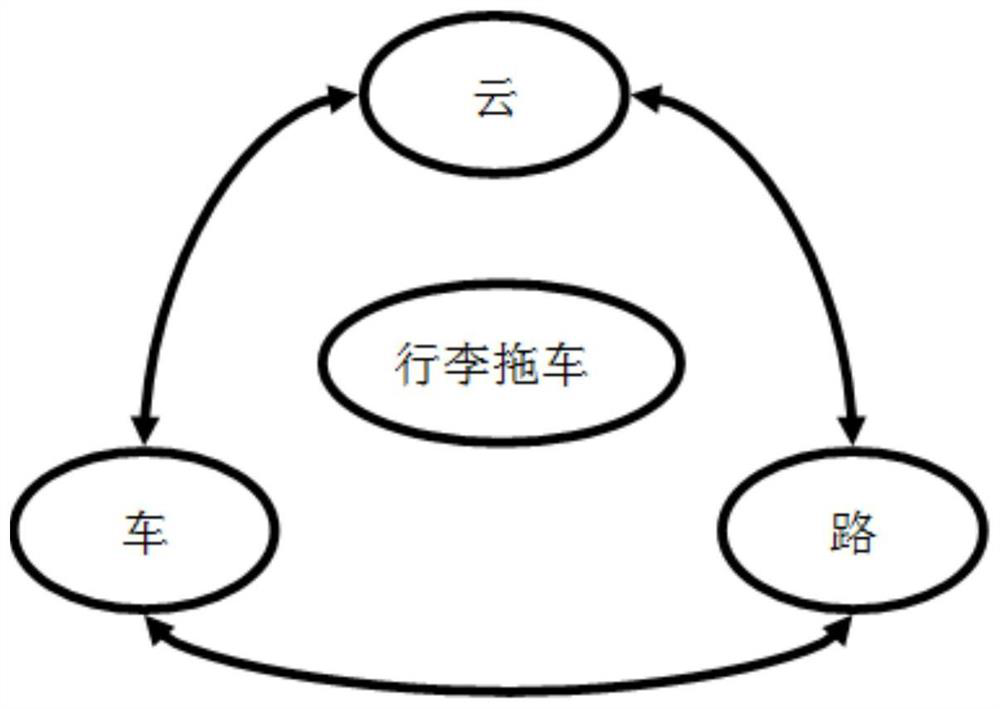

Automatic driving luggage trailer for airports

PendingCN112793804ASafe and efficient operationSafe and efficient drivingFreight handling installationsItem transportation vehiclesAutopilotLidar

The invention relates to an automatic driving luggage trailer for airports. The automatic driving luggage trailer comprises a trailer head, wheels and at least one section of tray. A control module interacting with an upper system in the airport is arranged in the trailer head; a main laser radar used for monitoring the conditions around the trailer and a height detector used for limiting the height are arranged at the top of the trailer head; and each section of tray is provided with a weight detector. The control module can safely and efficiently control the automatic driving luggage trailer according to an instruction of the upper system; and during control, the main laser radar on the top of the trailer head can monitor the condition around the trailer body in real time and feed back a monitoring result to the upper system, so that normal driving is prevented from being influenced by obstacles in a safe range in the driving process of the vehicle. The height detector can monitor the placing height of the goods on the vehicle, and thus the danger that the goods are prone to toppling over in the driving process when placed too high is avoided. The weight detector can monitor the load of the tray to ensure that the load is within a safe range, so that safe and efficient driving of the vehicle is realized.

Owner:中科大路(青岛)科技有限公司

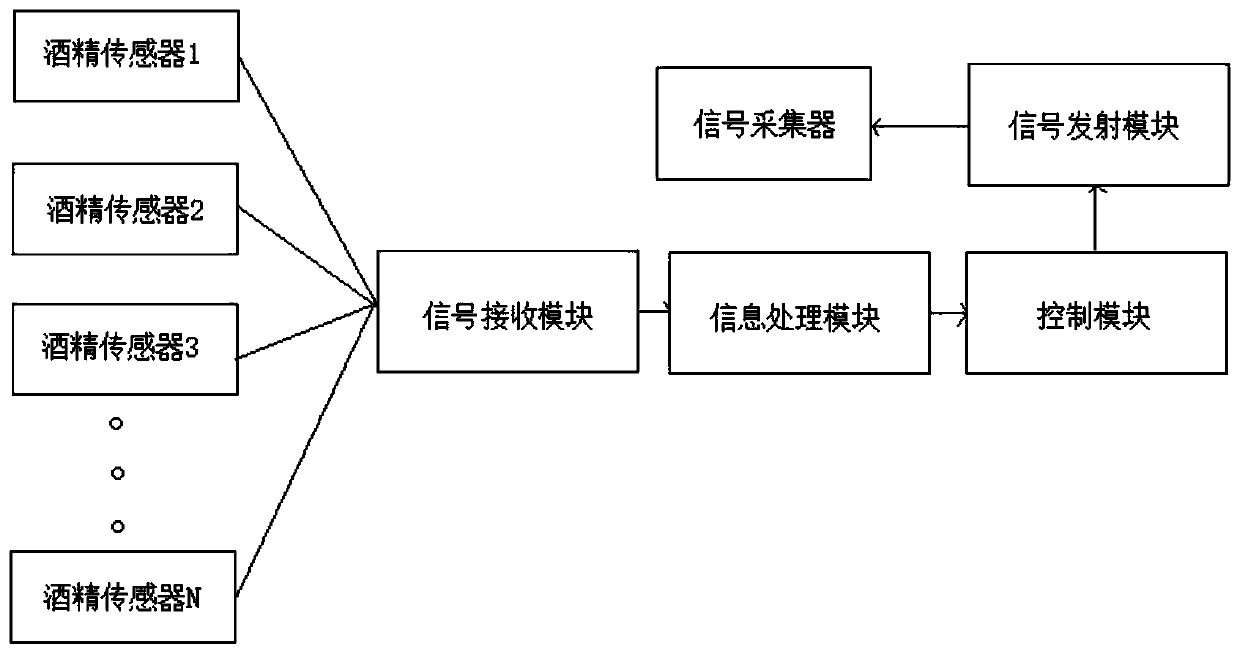

Drunk driving prevention monitoring and control system

PendingCN110481318AAffect normal drivingComprehensive monitoring of alcohol concentration distributionTractorsPropulsion unit safety devicesInformation processingControl system

The invention discloses a drunk driving prevention monitoring and control system, which belongs to the technical field of traffic safety monitoring systems, and comprises a plurality of alcohol sensors, a signal receiving module, a control module, a signal transmitting module, a signal collector and an information processing module, wherein the alcohol sensors are uniformly distributed at all corners in an automobile, the signal receiving module is connected with the alcohol sensors, the information processing module is connected with the signal receiving module, the control module is connected with the information processing module, the signal transmitting module is connected with the control module, and the signal collector is connected with the signal transmitting module. Whether a driver has a drunk driving behavior or not can be monitored, meanwhile, a monitoring system can be prevented from being damaged manually, and the drunk driving phenomenon can be effectively reduced; the system has very important significance in reducing traffic accidents caused by drunk driving and guaranteeing the life and property safety of people, and has very high application and popularization value.

Owner:NANNING UNIV

Anti-deformation wear-resistant asphalt pavement structure and construction process thereof

ActiveCN111910483AImprove load-bearing strengthAvoid deformationPaving gutters/kerbsClimate change adaptationElectric machineryDrive motor

The invention discloses an anti-deformation wear-resistant asphalt pavement structure which comprises an asphalt road, bases installed on the ground are arranged on the two sides of the asphalt road,steel column pipes are arranged on the bases, and protective plates are hinged to the inner sides of the bottoms of the steel column pipes. According to the structure, the weight sensing area senses the weight of a passing vehicle, the PLC receives a signal of the weight sensing area to control the driving motor I to work, and the driving motor drives the traction block to move upwards through thelead screw, so that the end part of the steel cable extends to drive the protection plate to rotate around the hinge seat until the lower end surface of the protection plate is attached to the asphalt road; and then the PLC controls the driving motor I to stop working, the driving motor II to rotate and the driving motor II to drive the steel ropes to move to two sides of the asphalt road, so that the steel ropes are prevented from influencing normal running of passing vehicles, the bearing strength of the asphalt road is enhanced, the asphalt road is prevented from deforming due to large bearing, and the service life of the asphalt road is prolonged.

Owner:NANTONG ROAD & BRIDGE ENG CO LTD

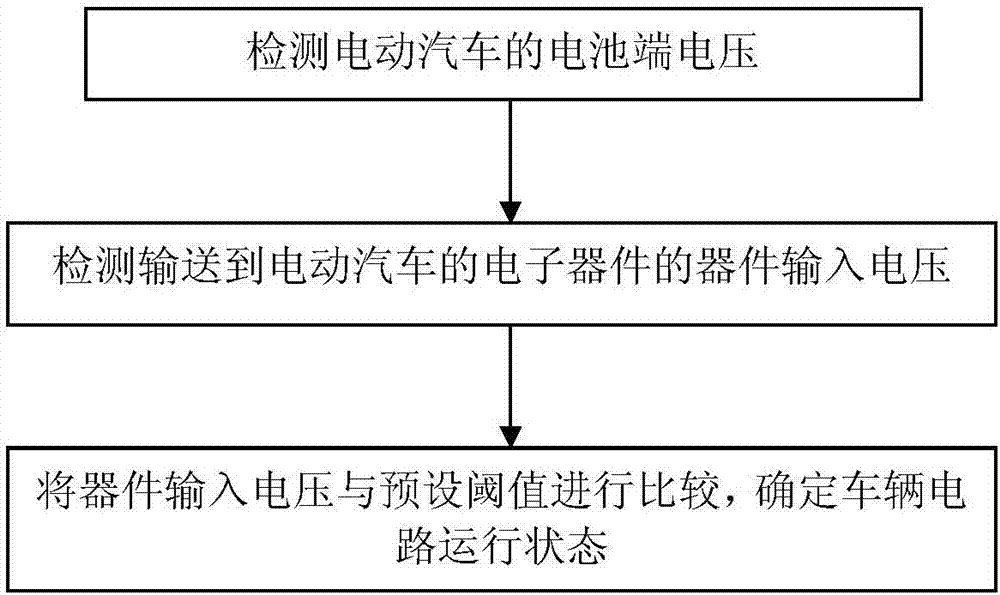

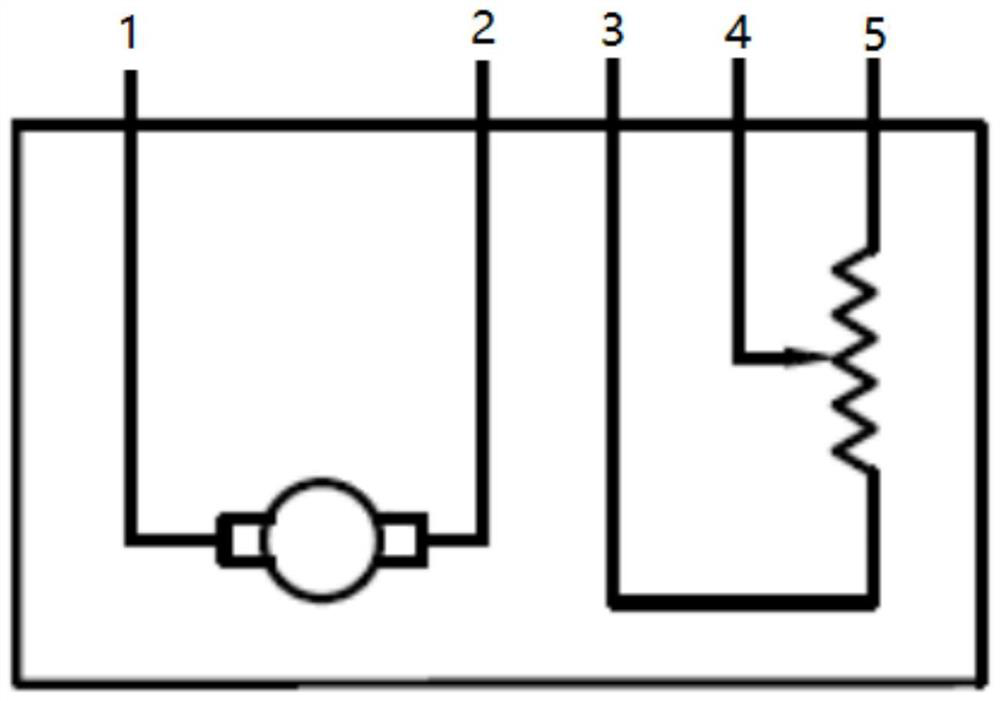

Monitoring method for vehicle circuit running state

InactiveCN107415698AAffect normal drivingInaccurate affects normal operationElectric devicesVehicular energy storageElectricityElectric vehicle

The invention provides a monitoring method for the vehicle circuit running state in order to solve the problems that after a battery of an electric vehicle is replaced, battery mounting is not standard, battery management system parameters are short of adjusting and checking, and after battery replacing, a new battery needs to adapt to the power supply situation, so that electricity detection is not accurate, and safe operation of the vehicle is affected accordingly. The monitoring method comprises the steps that (1) the battery terminal voltage of the electric vehicle is detected; (2) the device input voltage of an electronic device transmitted to the electric vehicle is detected; and (3) the device input voltage is compared with a preset threshold value to determine the circuit running state of the vehicle.

Owner:成都环磊科技有限公司

Rainwater utilization system and urban road

InactiveCN106499034AIncrease profitReduce the probability of useSewerage structuresSewage drainingStormwaterEngineering

The invention relates to the field of urban construction, in particular to a rainwater utilization system and an urban road. The rainwater utilization system comprises a downwards concave water absorption system and a catch basin, wherein the downwards concave water absorption system is provided with an overflow port and multiple water inlets, and the multiple water inlets correspond to a road surface, so that water on the road surface can enter the downwards concave water absorption system; the catch basin is arranged on one side of the downwards concave water absorption system, and is located below the road surface; the downwards concave water absorption system is communicated with the catch basin by the overflow port, and the position of each water inlet is higher than the position of the overflow port. According to the rainwater utilization system, rainwater and seeping water can be fully utilized and stored, the urban rainwater drainage amount is reduced, further the load of urban drainage facilities is lowered, the scale of the urban drainage facilities is reduced, and further investment and operating costs of the urban drainage facilities are reduced.

Owner:YANCHENG INST OF TECH

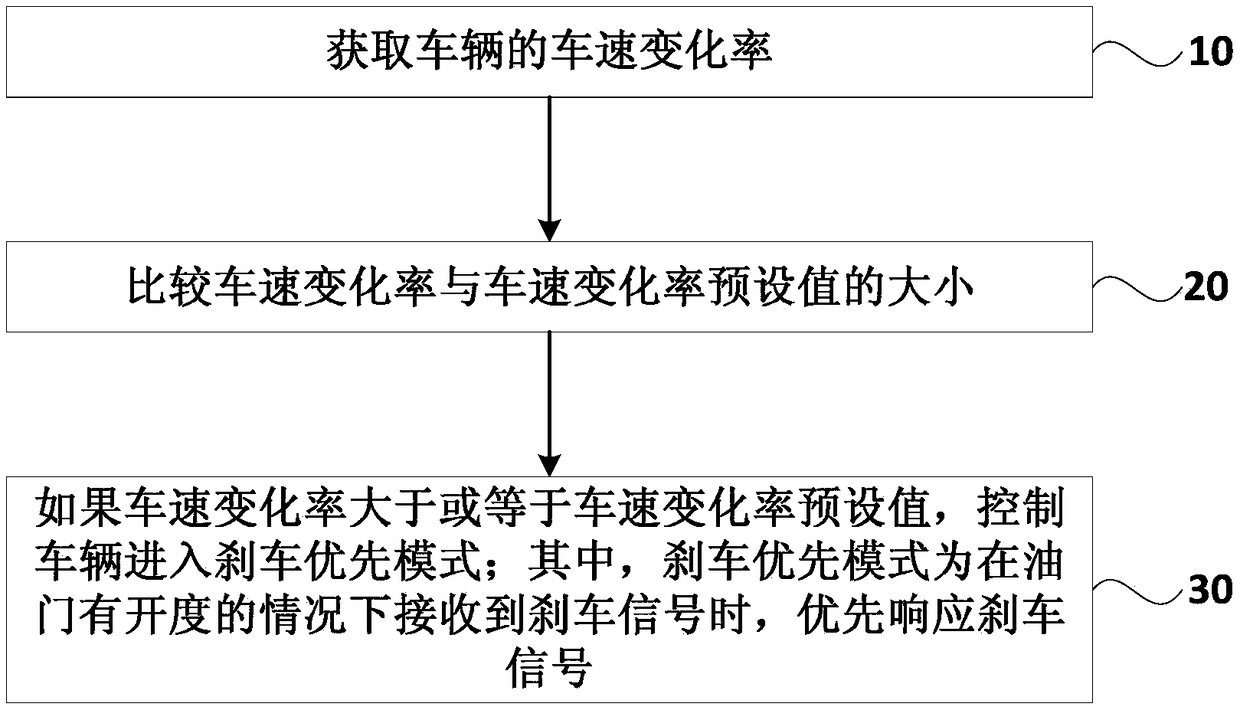

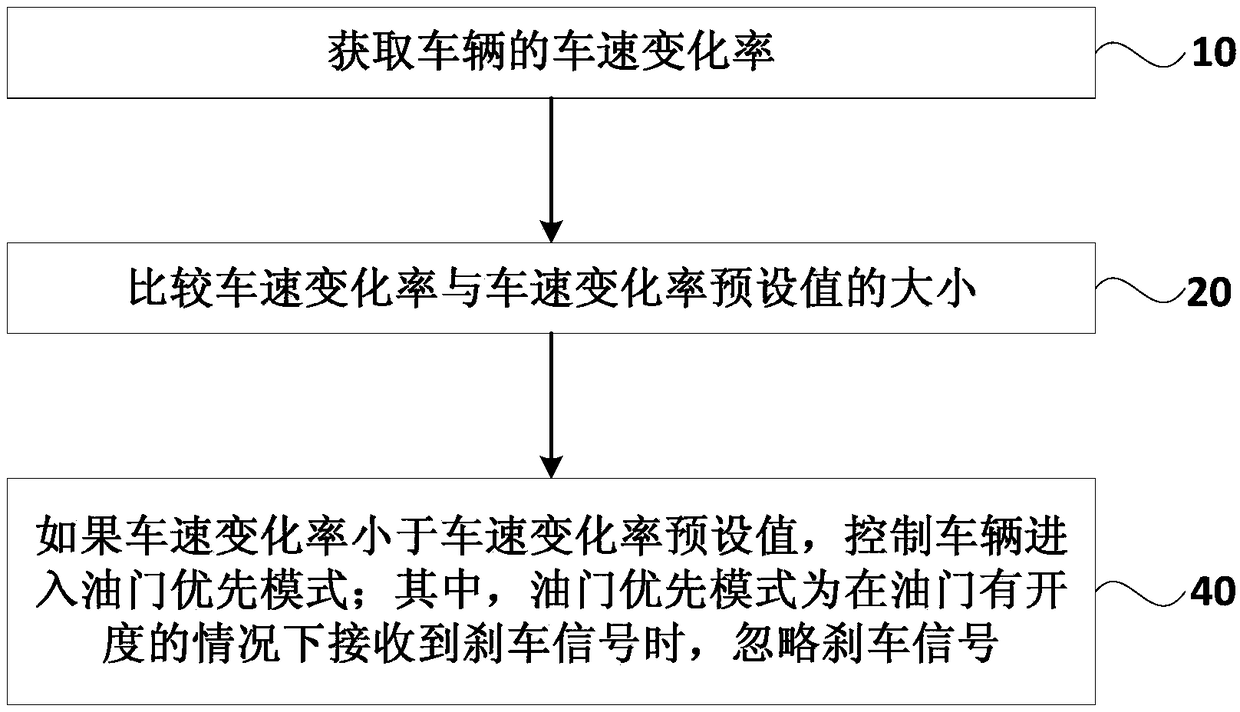

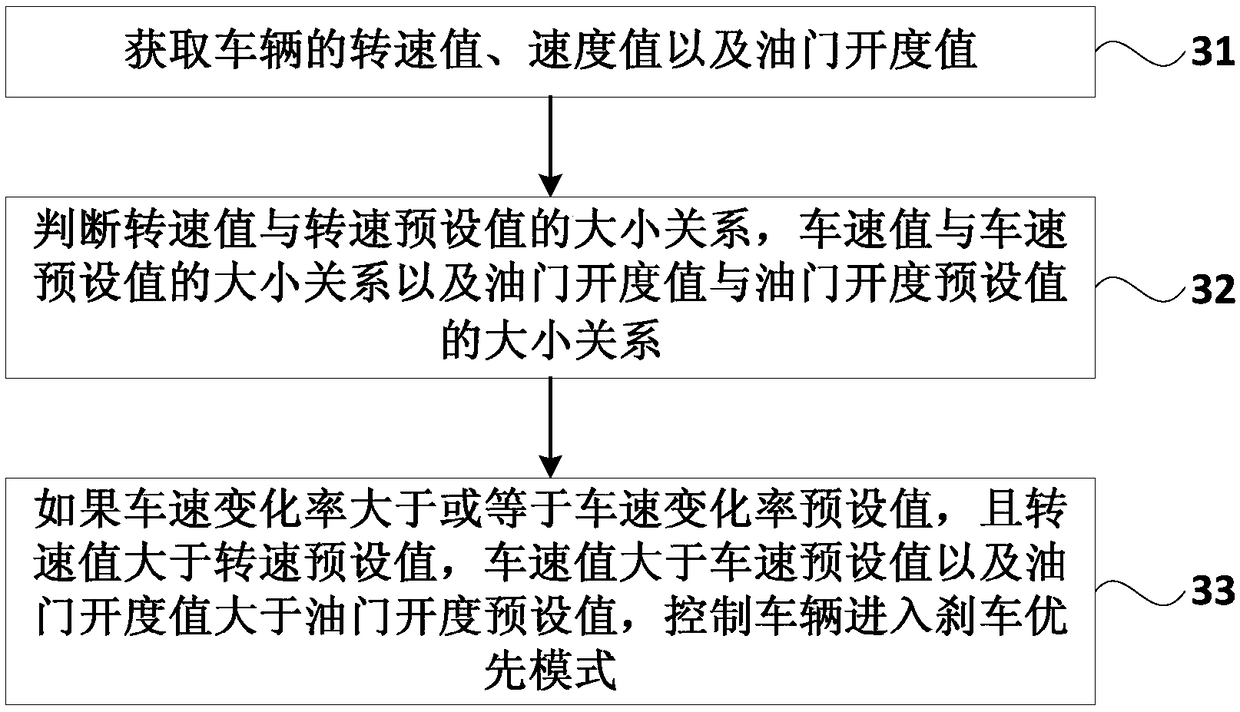

A vehicle control method and device, and a vehicle

ActiveCN109094536AAffect normal drivingEnsure safetyElectric/fluid circuitBrake action initiationsSignal onVehicle control

The invention discloses a vehicle control method and device, a vehicle. The vehicle control method comprises the following steps: acquiring a vehicle speed change rate of the vehicle; Comparing a magnitude of the vehicle speed change rate and a preset value of the vehicle speed change rate; Controlling the vehicle to enter a brake priority mode if the vehicle speed change rate is greater than or equal to the vehicle speed change rate preset value; Wherein the brake priority mode is to respond to the brake signal preferentially when a brake signal is received with an accelerator opening degree.By judging the relationship between the vehicle speed change rate and the preset value of the vehicle speed change rate and executing the brake signal only when the vehicle speed change rate is greater than or equal to the preset value of the vehicle speed change rate, the vehicle control method provided in this embodiment can avoid the influence of the accidental brake signal on the normal running of the vehicle and ensure the safety of the driver and the vehicle.

Owner:WEICHAI POWER CO LTD

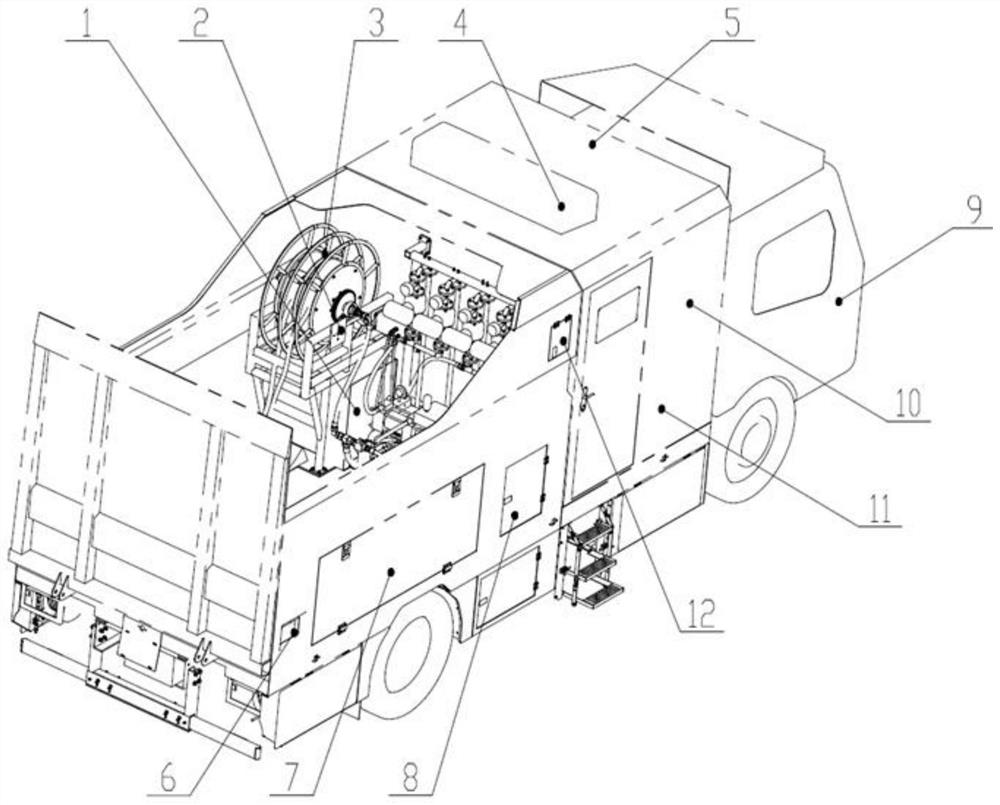

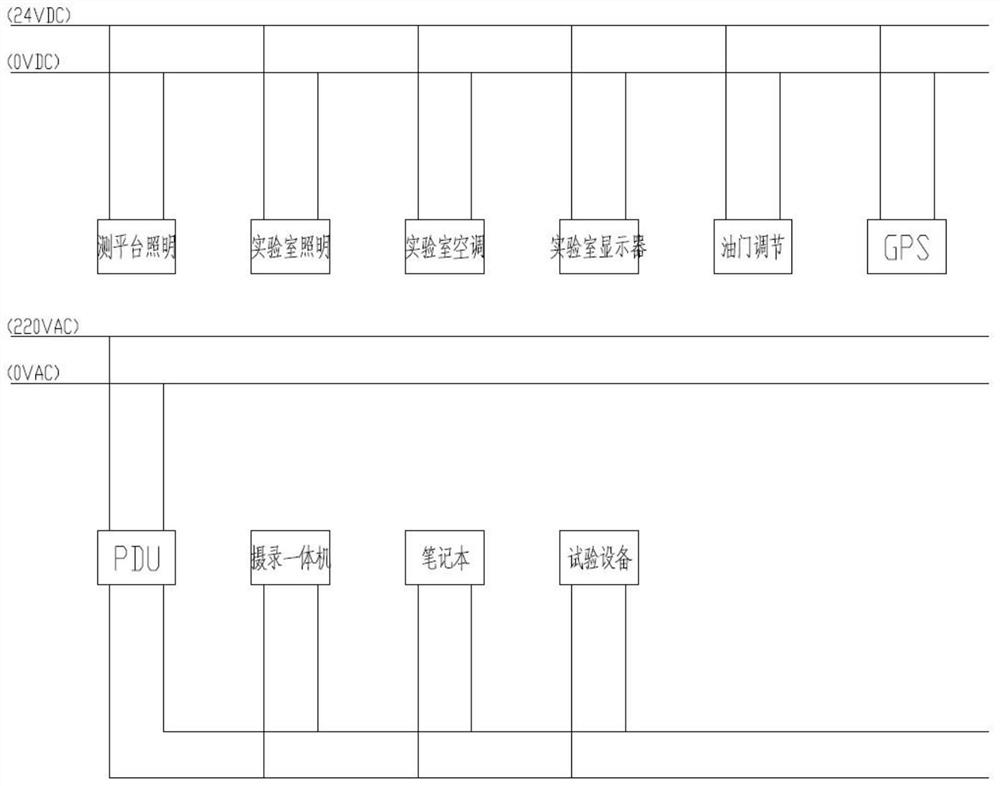

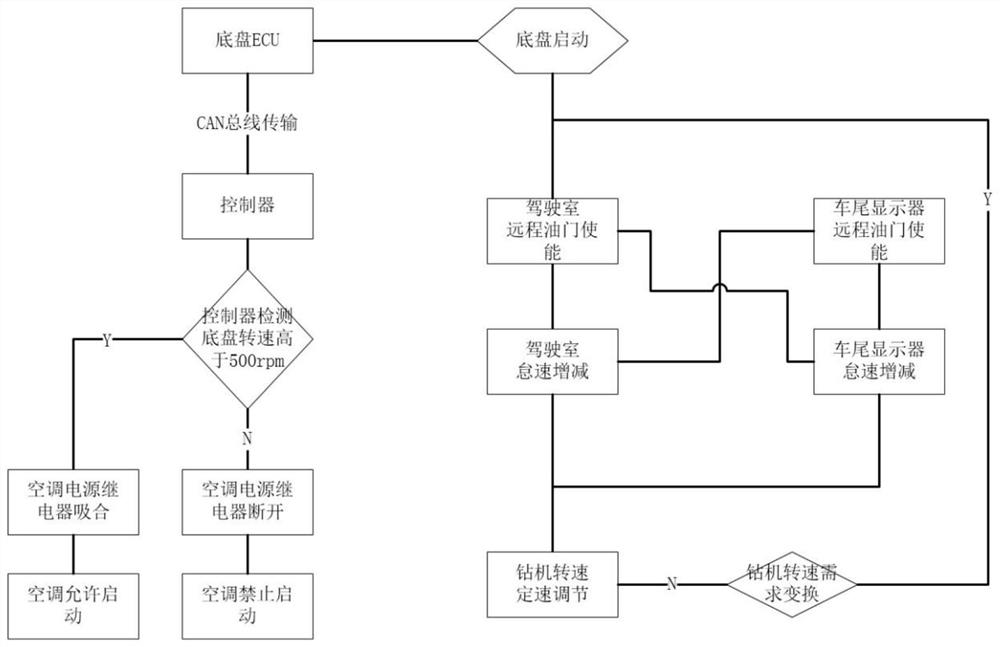

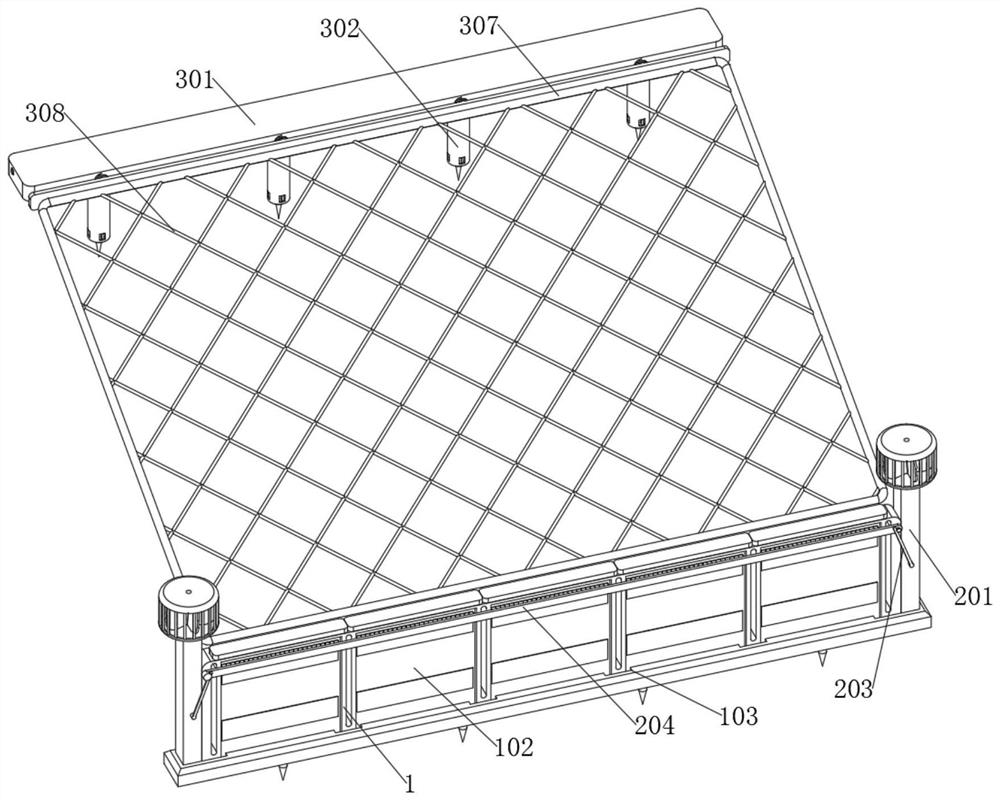

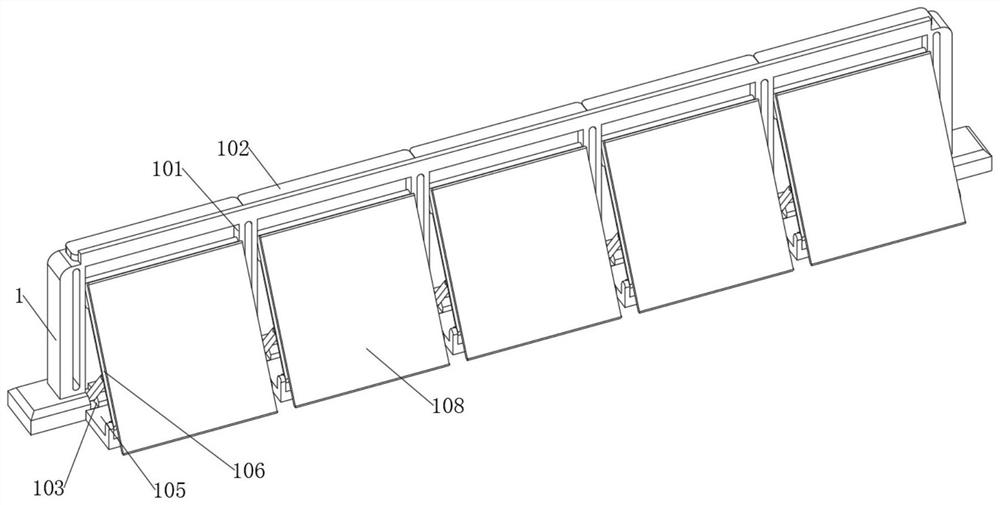

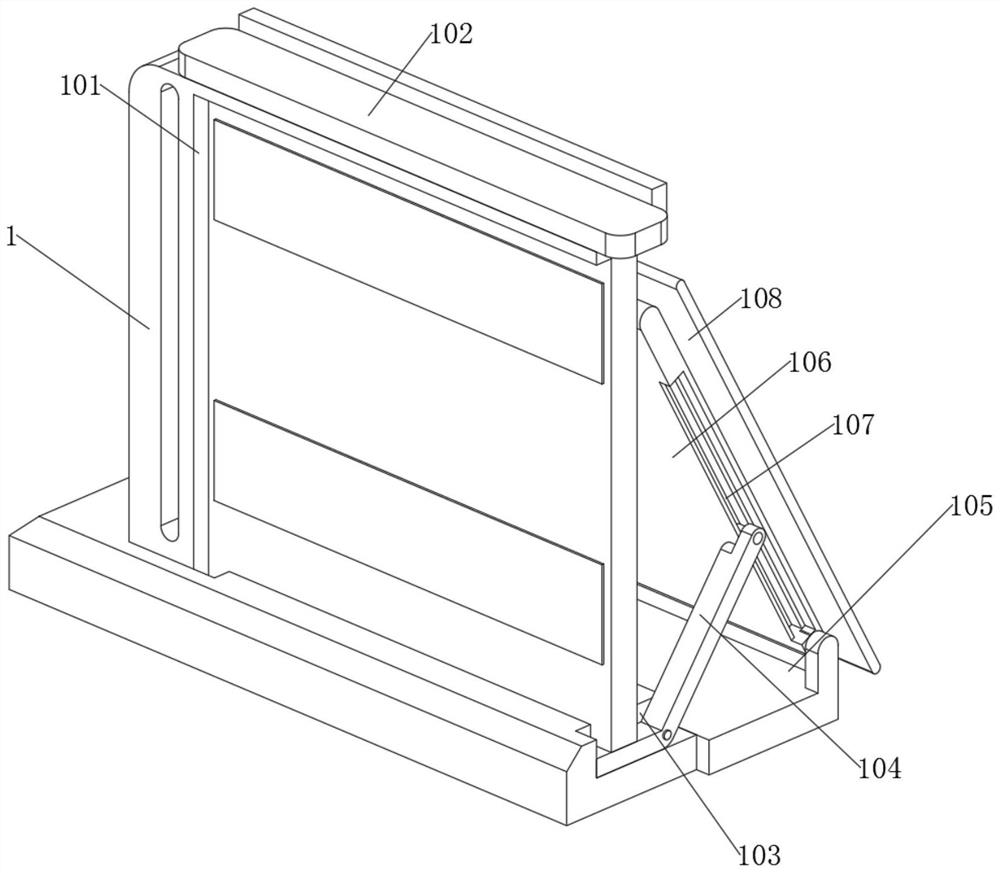

Whole-process auxiliary operation system of soil detection vehicle

ActiveCN112026624ASupervision is evidence-basedMeet Low Voltage LightingAir-treating devicesWithdrawing sample devicesAgricultural engineeringDisplay device

The invention discloses a whole-process auxiliary operation system of a soil detection vehicle. The whole-process auxiliary operation system comprises a soil drilling machine, a chassis, a cab, an experiment cabin, a switch positioning module, a monitoring platform and a power supply protection module. The positioning module is installed in the cab and matched with a photographing and recording all-in-one machine to check the position and the moving track of a vehicle in real time. The monitoring platform is mounted on one side of the experiment cabin and is used for monitoring and storing a side experiment platform and a operation field through a real-time view screen. The power supply protection module is installed in the experiment cabin and used for supplying power to mobile equipment,and the power supply protection module is powered by a generator set or an external power supply. An accelerator adjusting rocker switch is connected with a vehicle tail displayer through the controller, and virtual keys are arranged on the vehicle tail displayer. An air conditioning system is installed at the top of the experiment cabin and connected with a controller, and the controller is connected with a chassis ECU. According to the invention, the purposes of efficient and convenient sampling, testing and repairing processes and evidence-based process supervision can be achieved.

Owner:XUZHOU XUGONG ENVIRONMENTAL TECH CO LTD

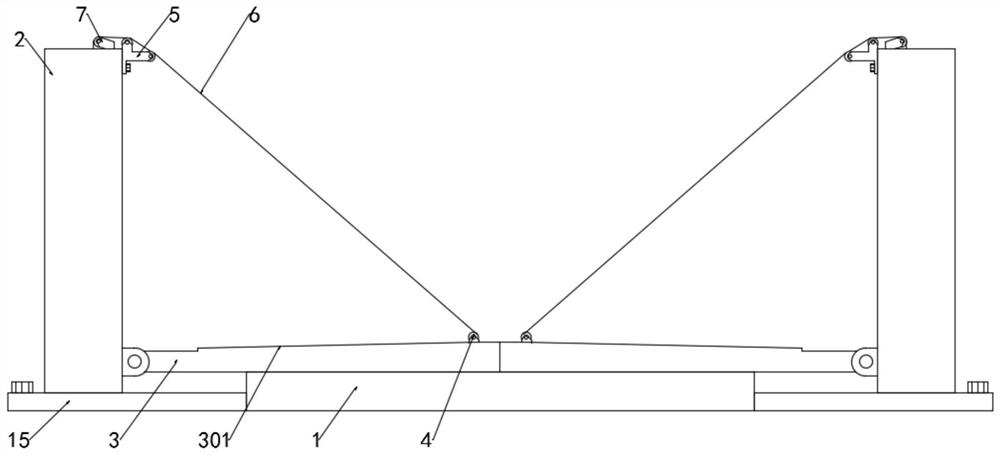

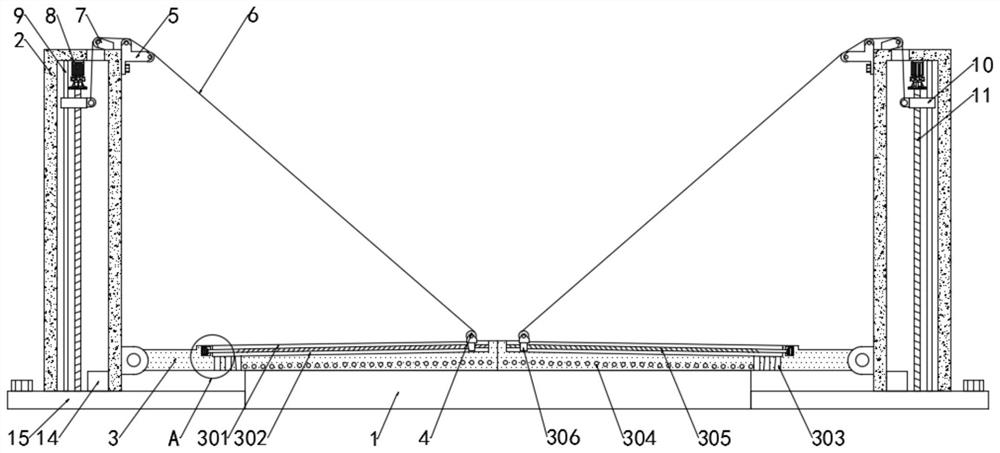

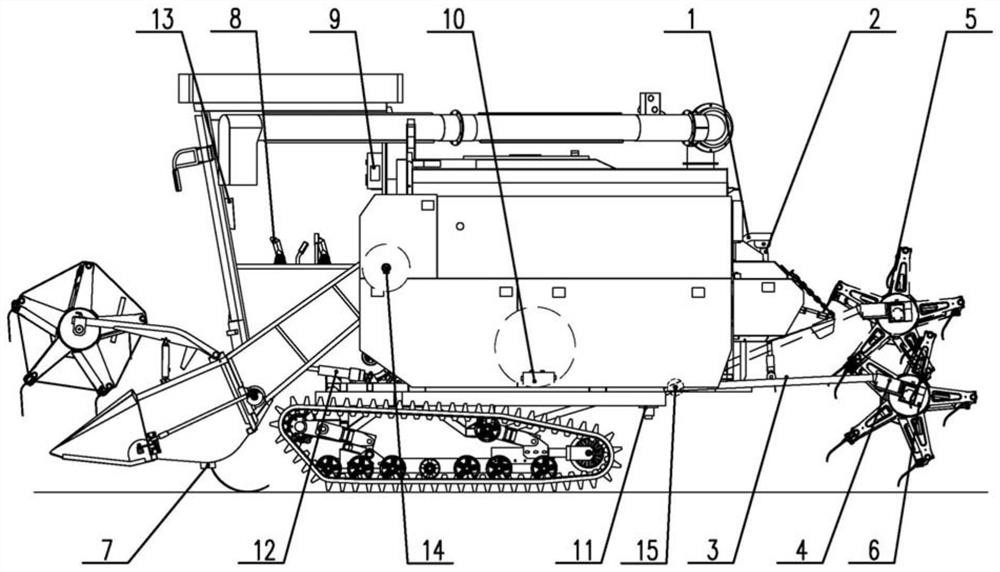

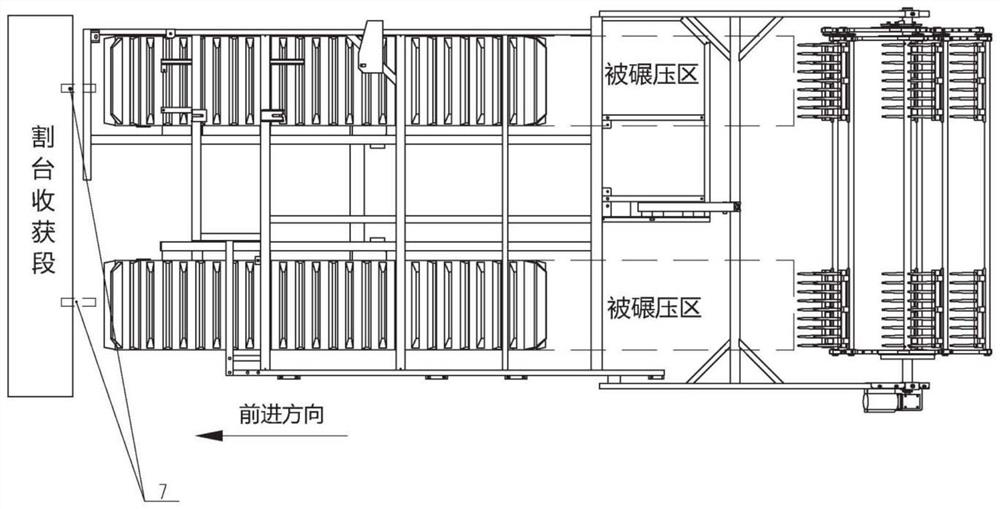

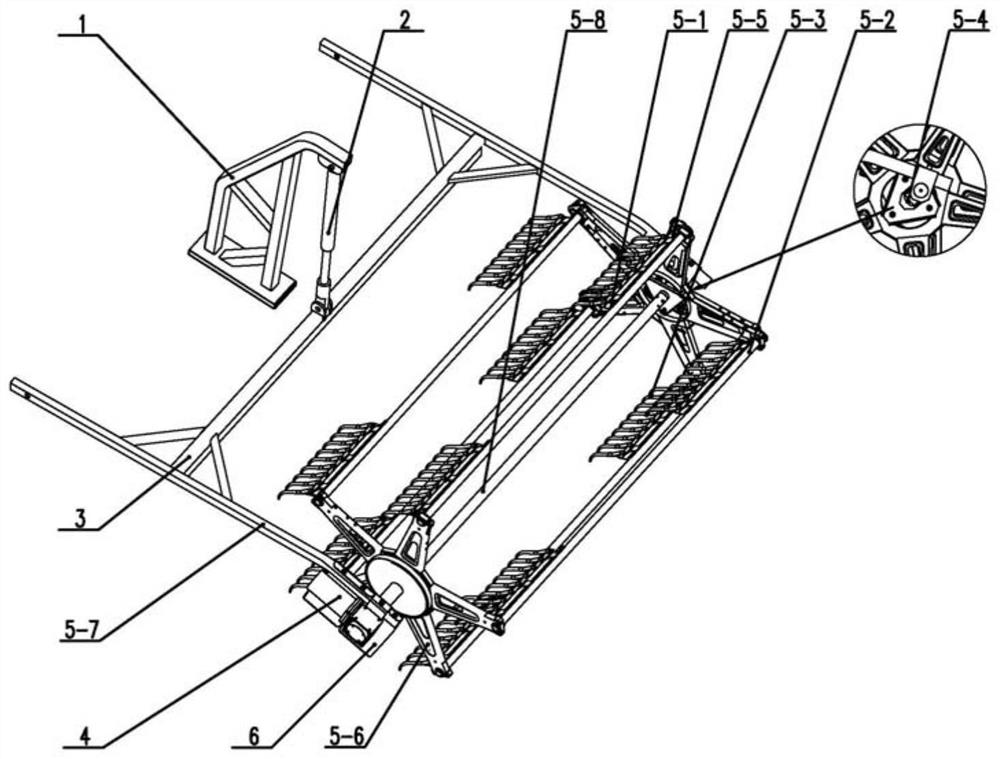

Self-adaptive regulation and control system and method for ratooning rice stubble cutting height and stubble supporting operation

ActiveCN114097430AHigh adjustment accuracyQuick responseAgricultural lifting devicesHeadersHydraulic cylinderControl system

The invention provides a ratooning rice stubble cutting height and stubble supporting operation self-adaptive regulation and control system and method. The ratooning rice stubble cutting height and stubble supporting operation self-adaptive regulation and control system comprises a stubble supporting device, a profiling contact type sensor, a speed radar and a controller. The stubble supporting device is arranged at the tail of the harvester and connected with the hydraulic cylinder support through a stubble supporting device hydraulic cylinder. The profiling contact type sensor is used for detecting the ground clearance of the header and transmitting the ground clearance to the controller; the speed radar is used for acquiring speed information of the harvester and transmitting the speed information to the controller; the hydraulic valve group is arranged on the chassis upper rack and is respectively connected with the header lifting hydraulic cylinder and the stubble supporting device hydraulic cylinder; the input end of the controller is connected with the profiling contact type sensor and the speed radar, and the output end of the controller is connected with the motor and the hydraulic valve set. While ratooning rice in the first season is harvested, stubbles rolled by the crawler belt or the wheel type walking device are righting, the integration of ratooning rice harvesting and righting can be effectively achieved, and the yield loss of the second season is reduced.

Owner:JIANGSU UNIV

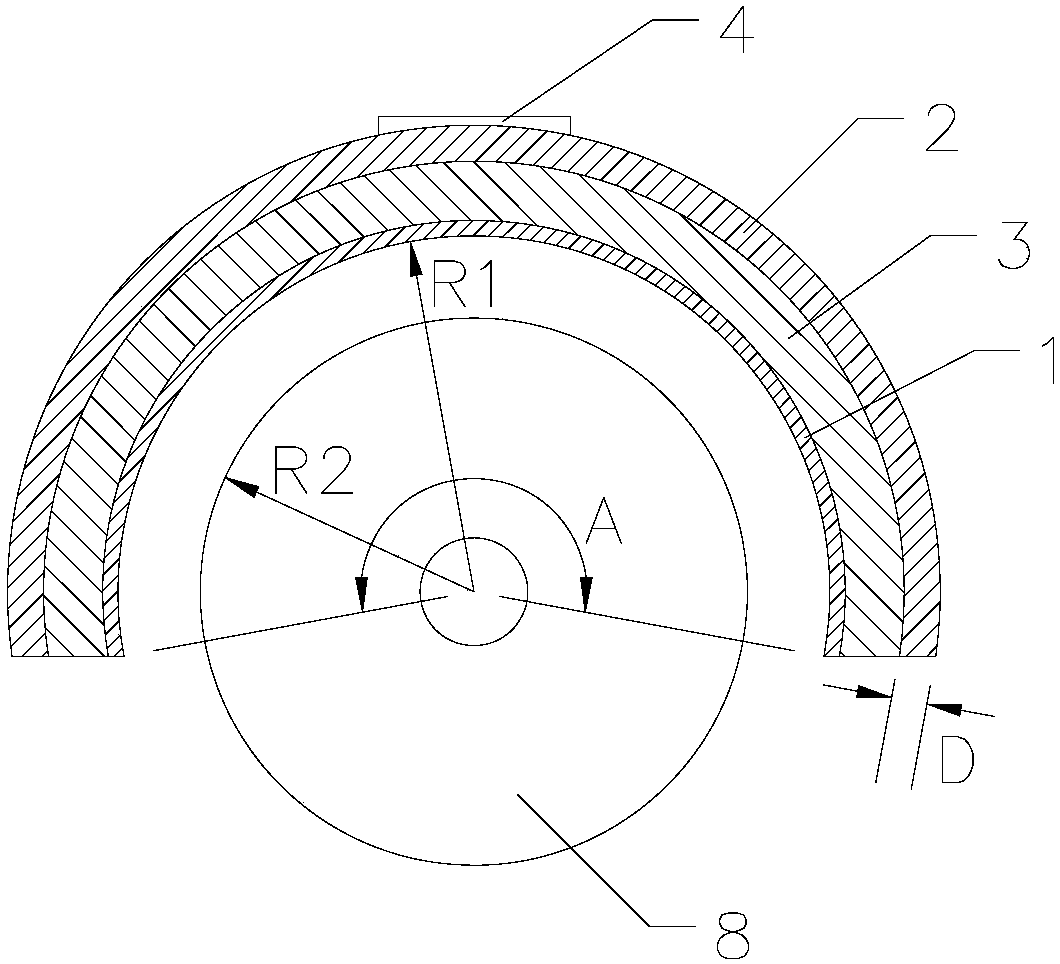

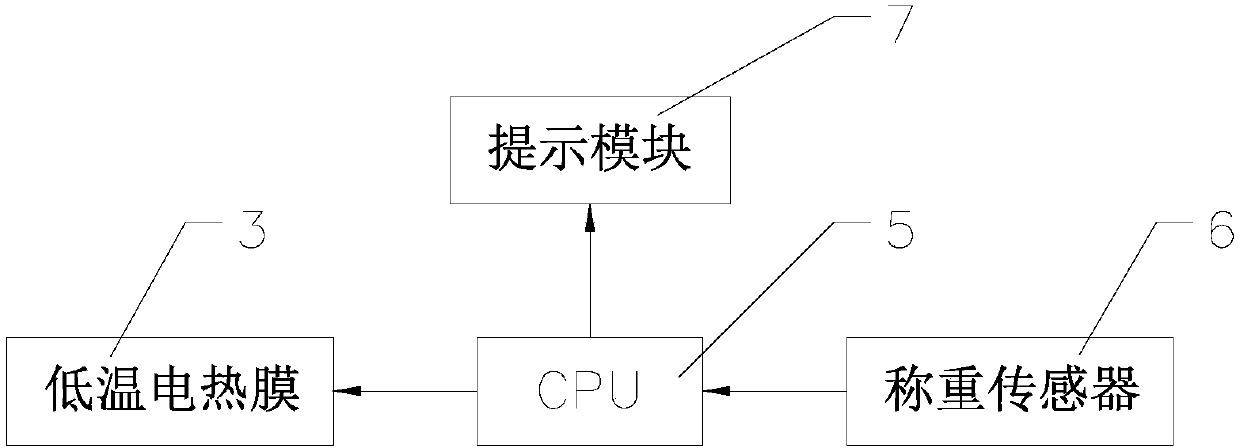

Automobile mudguard

ActiveCN107901987AAvoid damageAffect normal drivingSuperstructure subunitsVehicle cleaningThermal energySnow melting

The invention provides an automobile mudguard. The automobile mudguard includes a heat conduction layer arranged to be near a tire, a heat insulating layer arranged to be away from the tire and a low-temperature electric heating film arranged between the heat conduction layer and the heat insulating layer. The low-temperature electric heating film transforms the electric energy into heat energy, and transmits the heat energy to snow attached between the heat conduction layer and the tire so that the snow can be fast melted, and normal running of an automobile is avoided. The heat insulating layer is provided with a fixing plate. The automobile mudguard and an automobile body are connected into a whole through the fixing plate. The fixing plate is provided with a CPU and a weighing sensor used for measuring the weight added on the automobile mudguard. The weighing sensor and the low-temperature electric heating film are connected with the CPU. The preset weight is set in the CPU. When the added weight measured by the weighing sensor is greater than the preset weight, it is judged that much snow is attached between the tire and the mudguard, the CPU controls the low-temperature electric heating film to be heated to make the snow melt quickly and avoid the influence of the snow on automobile driving, and automobile driving can be safer accordingly.

Owner:PINGHU AICHIWEI AUTO PARTS

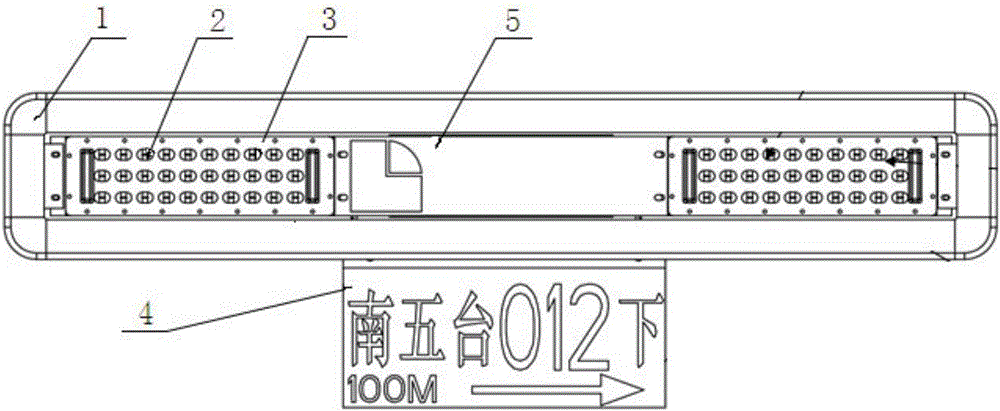

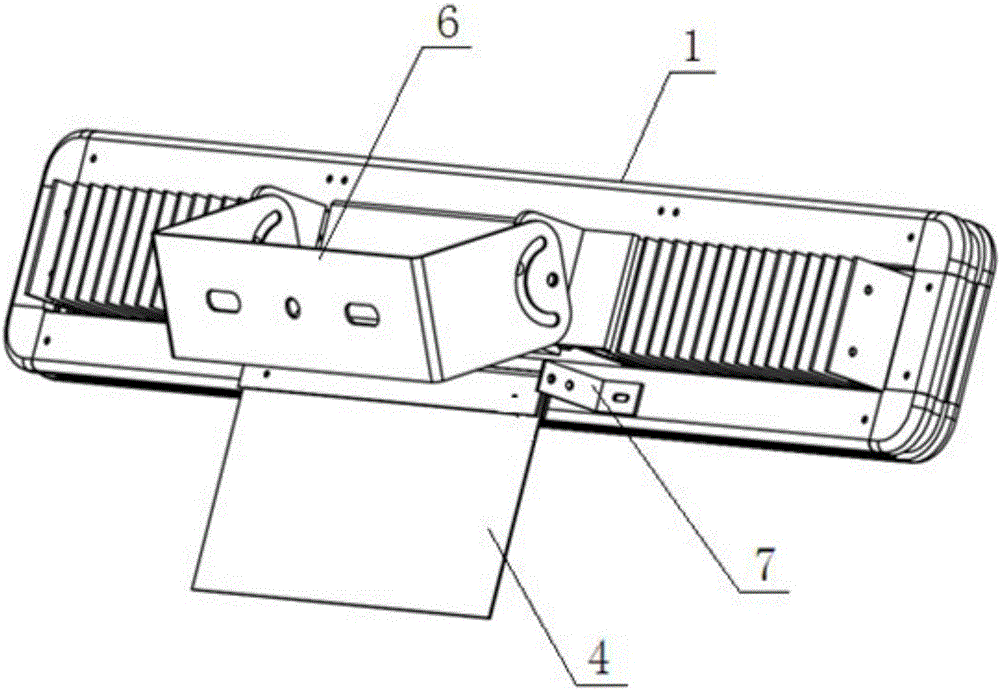

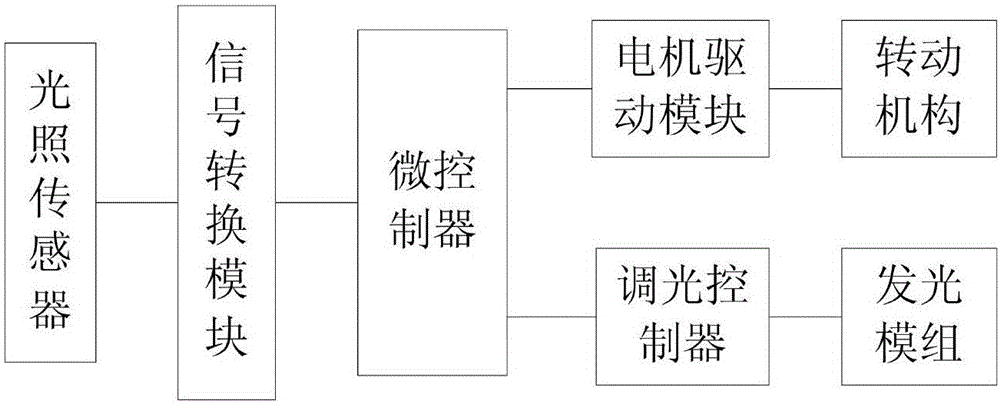

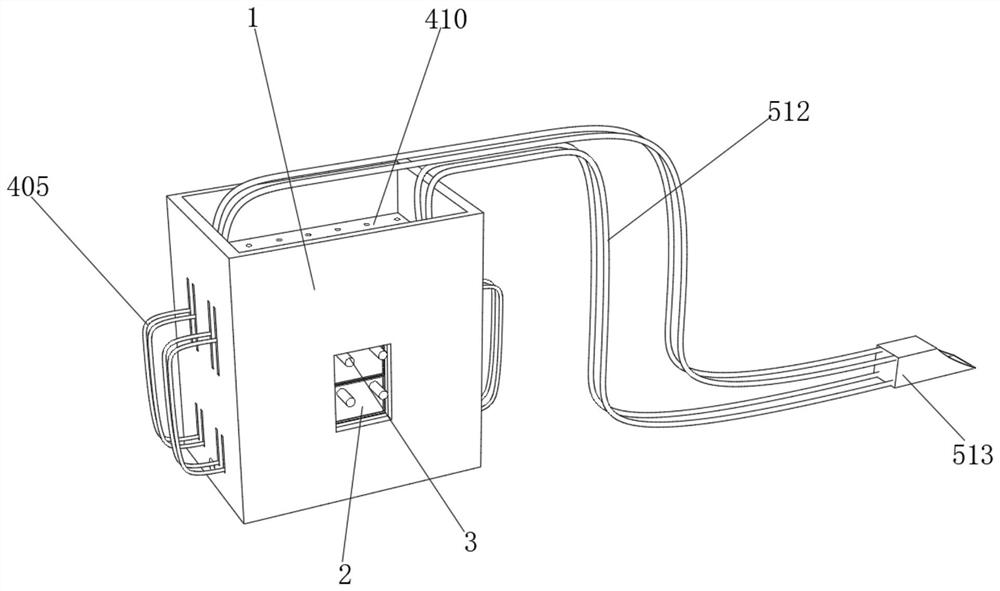

Anti-glare tunnel lamp

InactiveCN106122832AIrradiation angle adjustablePrevent glareElectric circuit arrangementsLighting heating/cooling arrangementsMicrocontrollerMotor drive

The invention discloses an anti-glare tunnel lamp. The anti-glare tunnel lamp comprises a shell, a hanging frame, light-emitting modules and a control device. The light-emitting modules are arranged on the shell. A fixed rotating shaft is arranged on the back portion of the shell. The hanging frame is connected with the fixed rotating shaft. A rotating mechanism is arranged on the hanging frame. Polarization covers are arranged outside the light-emitting modules. Light-transmitting curved surfaces are arranged on the polarization covers. The light-transmitting curved surfaces and lamp beads on the light-emitting modules are correspondingly arrayed. The control device comprises a microcontroller and a motor drive module. The output end of the microcontroller is connected with the motor drive module. The output end of the motor drive module is connected with the rotating mechanism. According to the anti-glare tunnel lamp, the polarization covers are arranged on the light-emitting modules and conduct dispersion on illumination of the tunnel lamp; and the rotating mechanism is controlled through the control device, so that the illumination angle of the tunnel lamp is regulated, and the safety of tunnel driving is improved.

Owner:XIAN LIXIANG HUAXIA TECH INNOVATION

Battery placing device of new energy vehicle

PendingCN113909236AAffect normal drivingImprove dust removal effectElectrostatic separationHollow article cleaningPower batteryElectrical battery

The invention provides a battery placing device of a new energy vehicle, and relates to the technical field of new energy vehicles. The battery placing device of the new energy vehicle comprises a housing, a power battery, output interfaces, a dust removal mechanism, a heat dissipation mechanism and a sealing strip, wherein the power battery is arranged in the middle in the housing; the output interfaces are evenly and fixedly connected to the front side and the rear side of the power battery; the dust removal mechanism is fixedly connected to the bottom end of the power battery; the heat dissipation mechanism is fixedly connected to the outer side of the power battery; and the outer side of the bottom end of the power battery is fixedly connected with the sealing strip, and the other end of the sealing strip is fixedly connected with the inner side of the housing. The heat dissipation effect on the power battery is enhanced through the heat dissipation mechanism, and the situation that the cleaning effect on dust at the top end of the power battery is affected due to the fact that friction between the power battery and the housing affects upward pulling of an elastic bag by the power battery when the power battery jumps is prevented. According to the battery placing device of the new energy vehicle provided by the invention, the problem that heat dissipation of a power battery is affected by excessive dust accumulated at the top end of the power battery is solved.

Owner:王艺淇

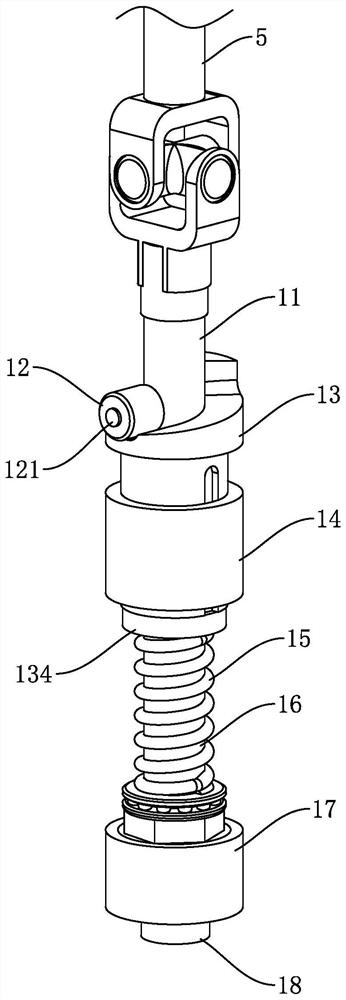

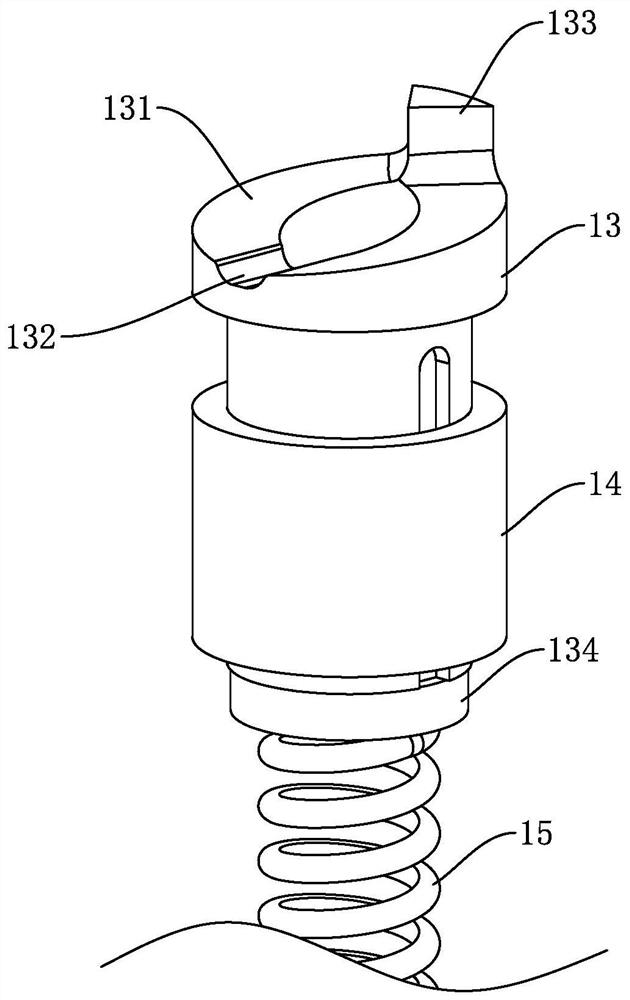

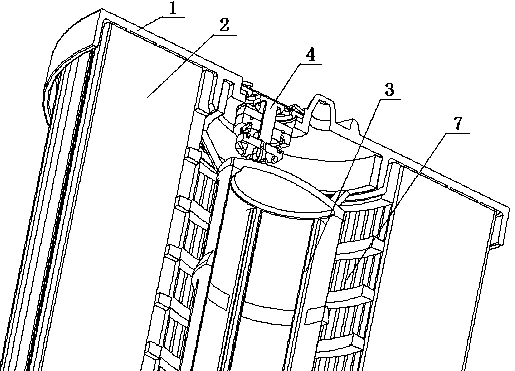

Self-aligning mechanism and steering gear assembly

PendingCN113276935AEasy to operateChange the operation mode of manual back-to-backSteering columnsDrive shaftStructural engineering

The invention relates to a self-aligning mechanism and a steering gear assembly, the self-aligning mechanism comprises a fixed shaft fixedly mounted on the outer side of an input shaft, and a bearing is rotatably mounted on the fixed shaft; a cam sleeve is slidably arranged on the outer side of the input shaft in a sleeving mode, the top face of the cam sleeve is an obliquely-arranged arc-shaped face and is in rolling fit with the outer wall face of the bearing, the outer side of the cam sleeve is in sliding fit with a spline sleeve, and the bottom end of the cam sleeve penetrates through the spline sleeve and extends downwards to abut against an elastic piece. A transmission shaft can be self-aligned, operation is convenient, the steering difficulty is lowered, and steering flexibility is improved; meanwhile, the cost input is reduced, the structure is simple, and maintenance is convenient.

Owner:潍坊新视听电子科技有限公司

Flexible protection structure based on road traffic design

PendingCN114775469AImprove stabilityPrevent fallingProtective constructionTraffic signalsArchitectural engineeringStructural engineering

The invention provides a flexible protection structure based on road traffic design, and relates to the technical field of road traffic facilities, the flexible protection structure comprises a main body, the bottom of the main body is provided with a base, the bottom of the main body is provided with a fixing bolt, the front side of the main body is provided with a chute, and the side surface of the main body is provided with a cleaning assembly; the cleaning assembly comprises side plates, the side plates are mounted on the two sides of the main body, and flow guide covers are mounted at the tops of the side plates; the fixing assembly is located above the main body, the fixing assembly comprises a protective net, and the bottom of the protective net is installed at the top of the main body. The buffer plate is inclined and buffers the impact force of the buffer plate on falling rocks under the action of the spring, so that the protective net is prevented from being damaged by large impact force, the falling rocks are prevented from influencing the normal running of a vehicle, the safety of a road is improved, and the problem that when an existing flexible protective structure is used, the service life is prolonged is solved. And the falling impact force of high falling rocks is large, so that the bottom of the net is easily damaged.

Owner:宋代学

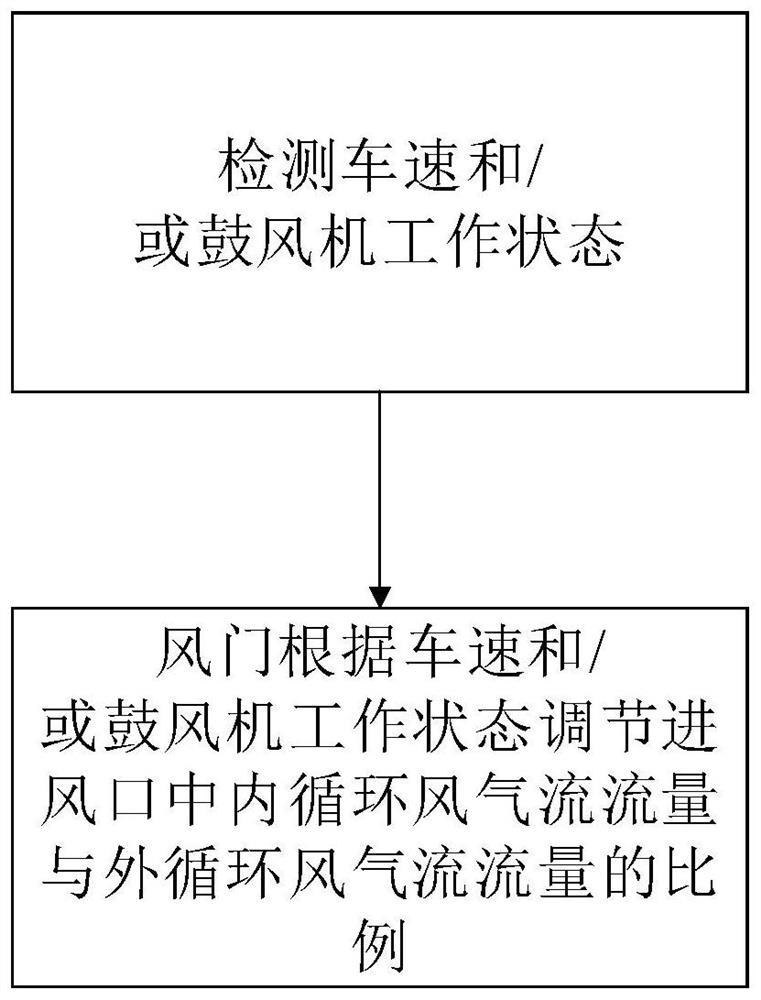

Control method for vehicle air-conditioning system and vehicle

InactiveCN112590491AAvoid enteringImprove heating effect in winterAir-treating devicesVehicle heating/cooling devicesCold airHeating effect

The invention discloses a control method for a vehicle air-conditioning system and a vehicle. The air-conditioning system comprises an air inlet duct, the air inlet duct is provided with an air inletand an air outlet communicated with a cab; an air door is arranged at the air inlet and is suitable for adjusting the proportion of the airflow flow of the inner circulating air duct to the airflow flow of the outer circulating air duct in the air inlet, and an air blower is arranged in the air inlet duct; the control method for the vehicle air conditioning system comprises the steps that the vehicle speed and / or the working state of an air blower are / is detected; the air door adjusts the proportion of the internal circulation air flow rate to the external circulation air flow rate in the airinlet according to the vehicle speed and / or the working state of the air blower. According to the control method for the vehicle air conditioning system, the vehicle speed and / or the working state ofthe air blower are / is detected, the air door is controlled according to the working state to adjust the ratio of the internal circulation air flow to the external circulation air flow in the air inlet, the heating effect in winter is further improved, and cold air is prevented from entering a cab.

Owner:宝能(广州)汽车研究院有限公司

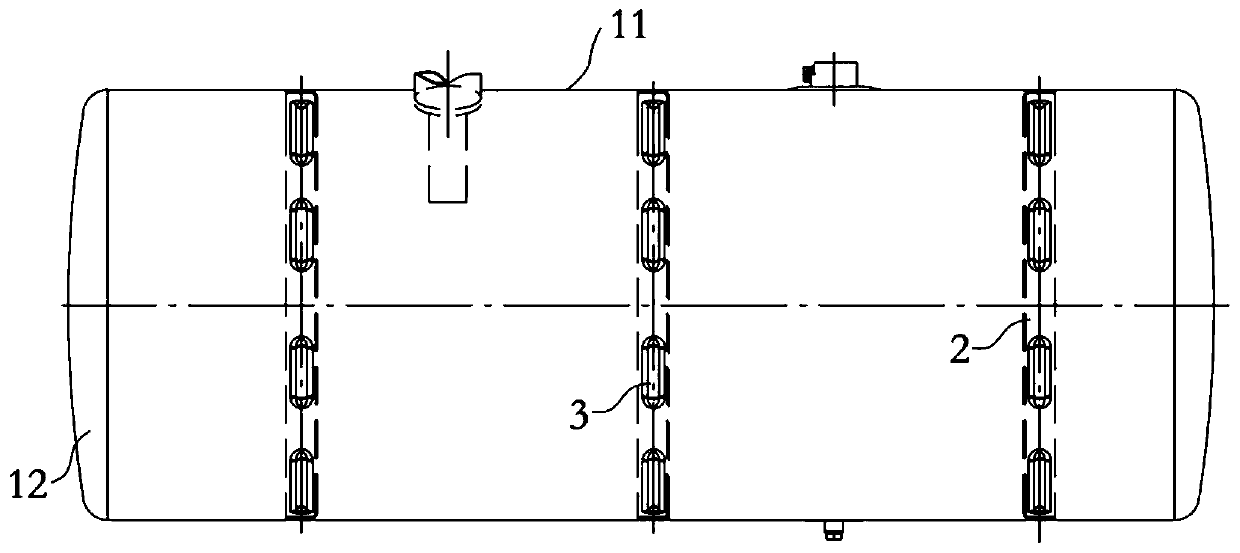

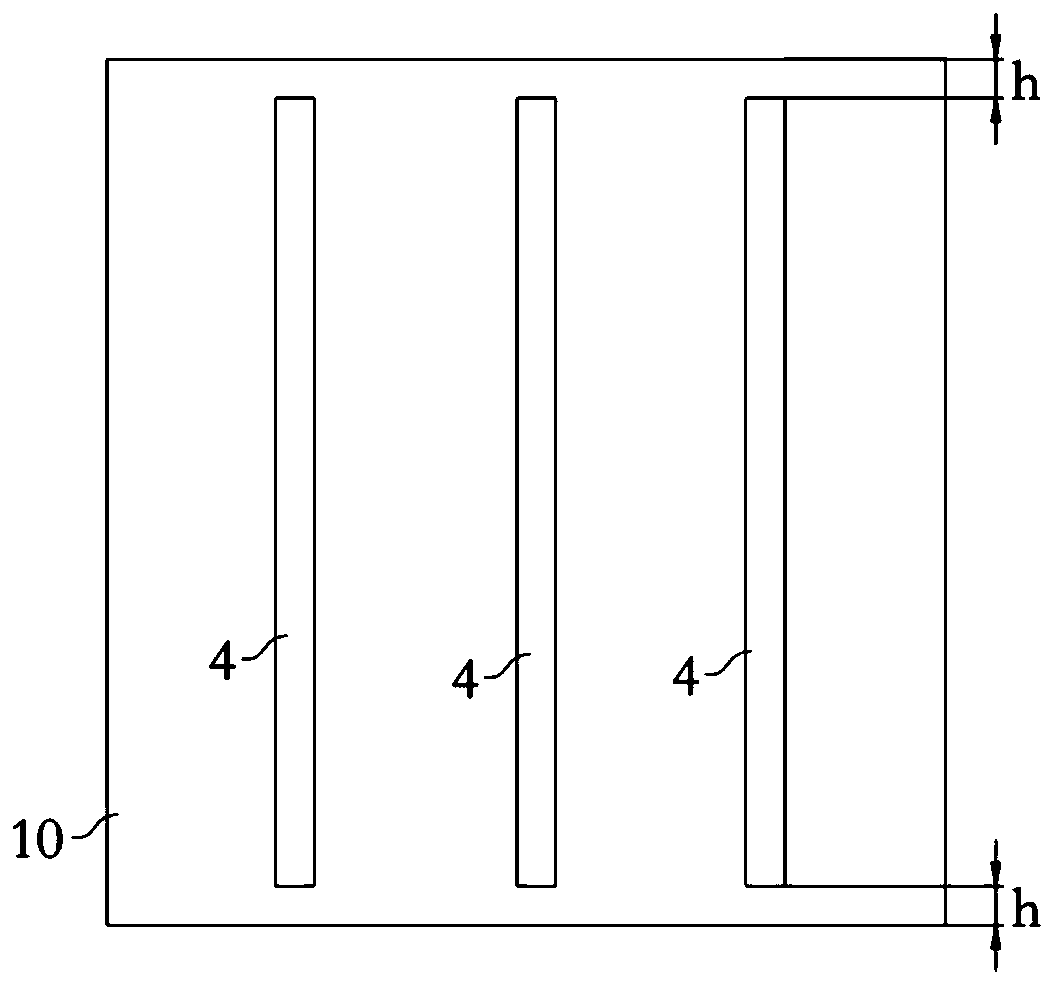

Fuel tank and assembling process thereof

ActiveCN110370921AReduce or even eliminate frictionEliminate frictionFuel supplyTectorial membraneFuel tank

The invention discloses a fuel tank and an assembling process thereof and belongs to the technical field of automobiles. The fuel tank comprises a fuel tank body and a partition plate which is arranged in the fuel tank body; and at least one of the peripheral face of the partition plate and the annular wall face, in corresponding abutting connection with the peripheral face of the partition plate,of the fuel tank body is provided with a protective film. The assembling process of the fuel tank comprises that the protective film is pasted to the peripheral face of the partition plate and / or theannular wall face, in corresponding abutting connection with the peripheral face of the partition plate, of the fuel tank body through bonding glue. Due to the fact that at least one of the peripheral face of the partition plate and the annular wall face corresponding to the peripheral face of the partition plate is provided with the protective film, when the partition plate is installed in the fuel tank body, the protective film is arranged between the partition plate and the fuel tank, so that when the partition plate moves relative to the fuel tank body, friction between the partition plate and the fuel tank body can be reduced and even be eliminated, therefore generation of aluminum dust can be generated, and it is avoided that the aluminum dust enters a subsequent precision mechanismto damage the precision mechanism and normal running of an automobile is affected.

Owner:FAW JIEFANG AUTOMOTIVE CO

Drainage filtering device for adjusting drainage port along with rainfall

The invention discloses a drainage filtering device for adjusting a drainage port along with rainfall. The device comprises a box body, a detection cavity with an upward opening is formed in the box body, three filtering cavities with upward openings are formed in the box body, and a drainage mechanism used for controlling opening and closing of a drainage hole is arranged in the box body. A telescopic plate with a built-in spring is fixedly connected to the rear inner wall of each filtering cavity, a compression cavity with a forward opening and a moving cavity are formed in the rear inner wall of each filtering cavity, and a moving plate is slidably connected into each moving cavity. The device is simple in structure, convenient to use and capable of adjusting the size of the drainage port according to rainfall, the situation that road surface water accumulation is caused by unsmooth drainage when the rainfall is large, and normal running of vehicles is affected is prevented, besides, rainwater can be filtered, and road surface sundries are prevented from blocking a sewer. The device can be sealed at ordinary times and can prevent the road environment from being influenced by sewer odor return.

Owner:上海塑茜劳防用品有限公司

Fuel filter core with safety valve

PendingCN109882326AGuaranteed to workAvoid damageMachines/enginesLiquid fuel feedersEngineeringFuel filter

The invention discloses a fuel filter core with a safety valve. The safety valve is arranged on the end cover surface of the filter core, under normal conditions, a seal part of the safety valve separates a hydrophobic cavity from the outside, the seal part is pressed and moved under emergency conditions, and the internal and external conduction is turned on; and a filter net is arranged between the hydrophobic cavity and a flow channel to filter fuel. According to the fuel filter core with the safety valve, after a filter layer is blocked, after overcoming the spring pressure of the safety valve, the internal and external pressure difference of a hydrophobic pipe assembly enables the safety valve to open downward, the diesel oil enters the filter core through the safety valve, flows alongan arc-shaped sphere at the top of the hydrophobic pipe assembly into the hydrophobic cavity, impurities and water are filtered from the hydrophobic cavity through the filter net on the hydrophobic pipe assembly, the filtered diesel oil is transmitted to an engine after entering an internal channel of the hydrophobic pipe assembly to ensure the normal operation of the engine, so that a vehicle maintains normal operation. The diesel oil is filtered by the hydrophobic net and then transmitted to the engine, and the damage caused by the impurities entering the engine to the precision parts suchas an oil pump and an injector is avoided.

Owner:无锡亿利环保科技有限公司

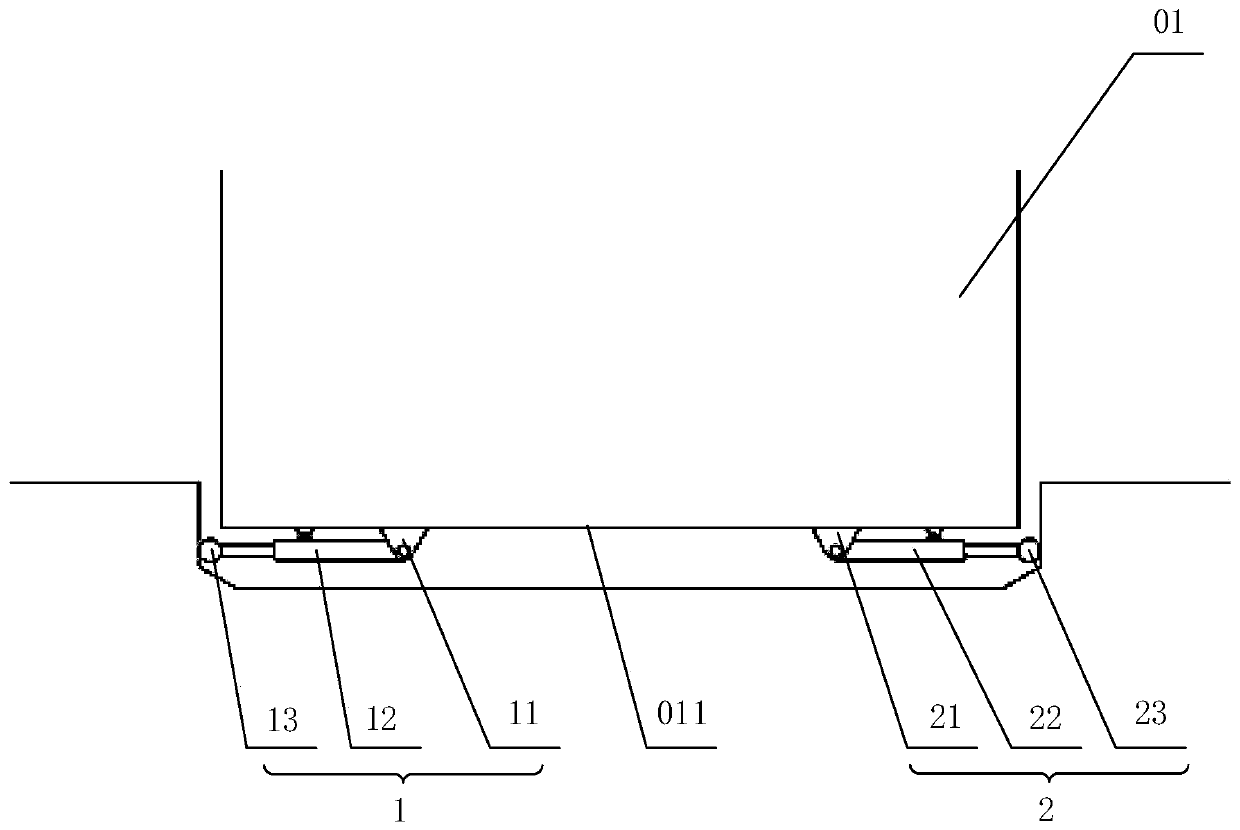

Suspended type monorail train and swinging stop device thereof

The invention discloses a swinging stop device of a suspended type monorail train. The swinging stop device comprises multiple sets of first swinging stop arms and second swinging stop arms. The firstswinging top arms and the second swinging stop arms are arranged on the two sides of a train body correspondingly and are stretched out and drawn back relative to the train body. When the train bodystops, the first swinging stop arms and the second swinging stop arms are all stretched out till abutting against abutting connection faces, the abutting connection faces are made to exert acting force on the two sides of the train body through the first swinging stop arms and the second swinging stop arms correspondingly to overcome the acting force exerted by passengers on the train body, and therefore the train body is prevented from swinging leftwards and rightwards; and because the first swinging stop arms and the second swinging stop arms are able to make the two sides of the train bodyevenly bear force, the swinging stop effect is better. When the train body runs, the first swinging stop arms and the second swinging stop arms are drawn back inwards, the first swinging stop arms andthe second swinging stop arms are made to get away from the abutting connection faces, and it is avoided that the normal running of the train body is influenced. Therefore, the swinging stop device of the suspended type monorail train can reliably and effectively prevent the train body from swinging. The invention further discloses the suspended type monorail train comprising the swinging stop device.

Owner:CRSC RAIL CAR CO LTD

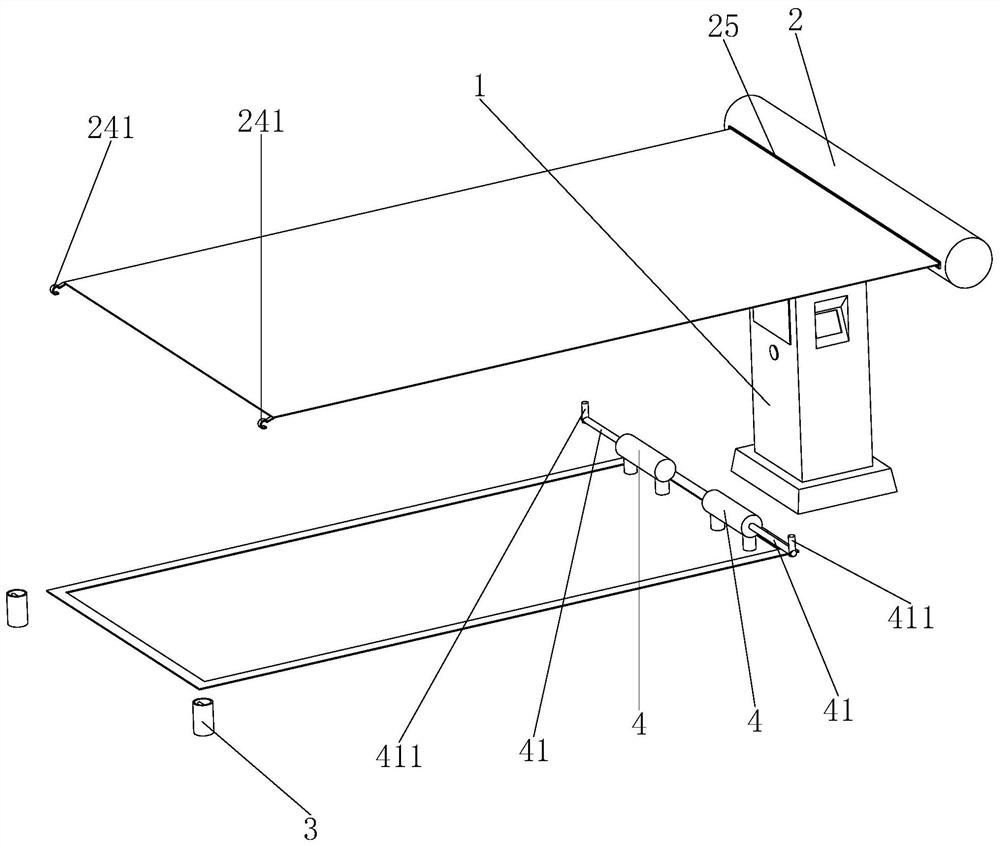

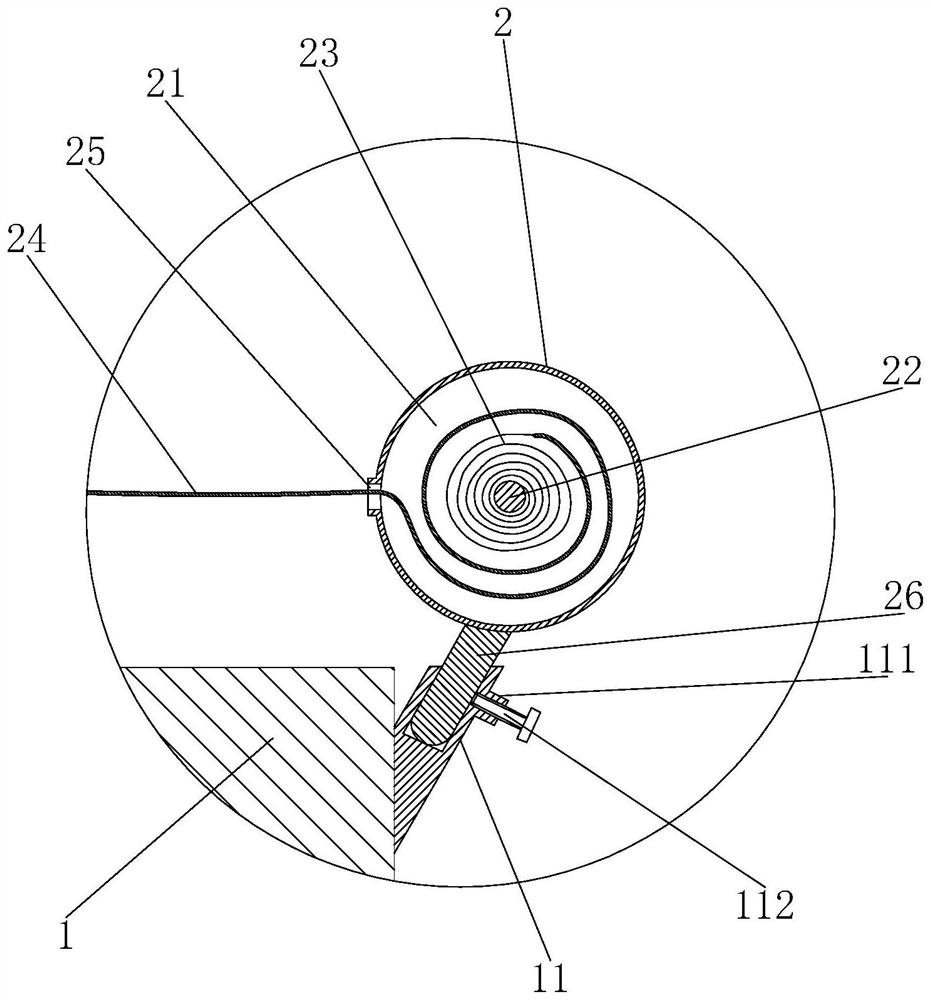

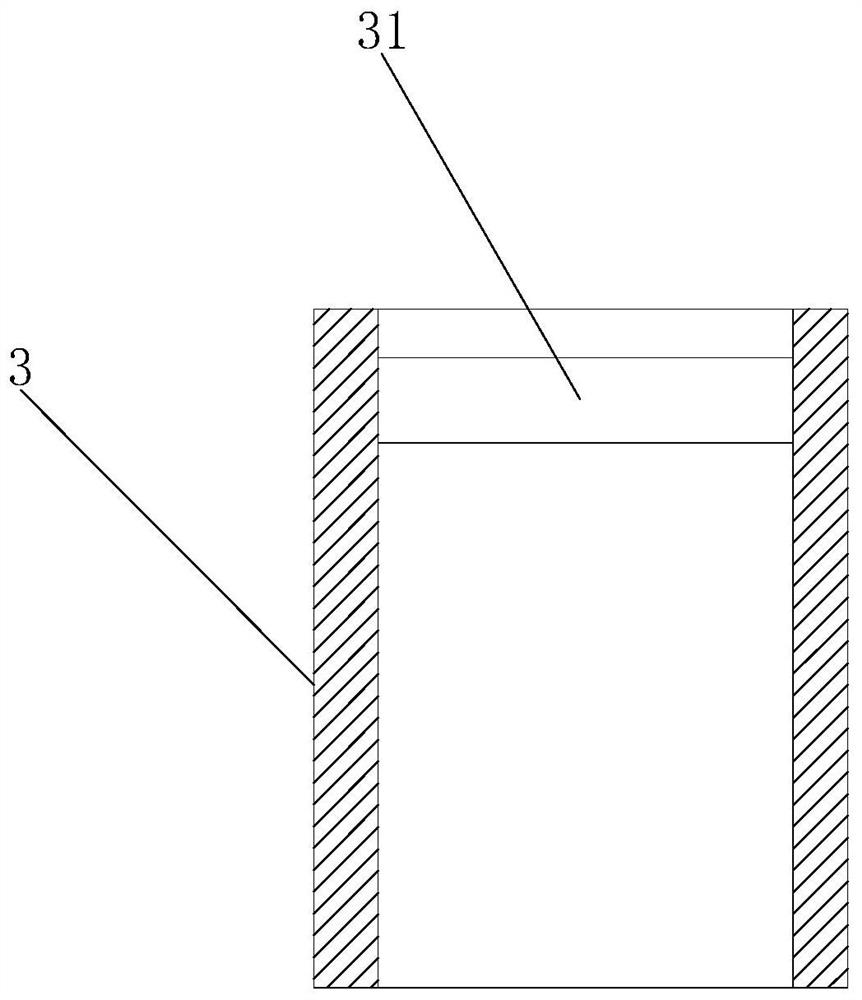

Parking lot charging pile assembly with sunshade function

InactiveCN113370817AEasy to useAffect normal drivingCharging stationsElectric vehicle charging technologyParking spaceCoil spring

The invention relates to the technical field of parking lot design, and discloses a parking lot charging pile assembly with a sunshade function, the parking lot charging pile assembly comprises a charging pile body located behind a parking space, the upper end of the charging pile body is provided with a storage column extending in the horizontal direction, the middle of the storage column is connected with the charging pile body, and the storage column is internally provided with a cavity layer; a fixing shaft extending in the horizontal direction is arranged in the middle of the cavity layer, reset coil springs with ends connected with the fixing shaft are arranged at the two ends of the fixing shaft, sunshade cloth wound around the outer sides of the reset coil springs is further arranged on the fixing shaft, and the ends, away from the fixing shaft, of the reset coil springs are connected to the end of the sunshade cloth. The storage column is provided with a long-strip-shaped opening allowing the end, away from the reset coil springs, of the sunshade cloth to penetrate through, lifting hooks are arranged on the two sides of the end, away from the reset coil springs, of the sunshade cloth, connecting sleeves fixed in the ground are arranged on the two sides of the end, away from the charging pile body, of the parking space, and first lifting rods connected with the lifting hooks are arranged at the upper ends in the connecting sleeves.

Owner:浙江喜鹊云互联系统科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com