Well lid construction installation method

An installation method and manhole cover technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as skewing, affecting normal road traffic, and endangering the safety of vehicles and pedestrians

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

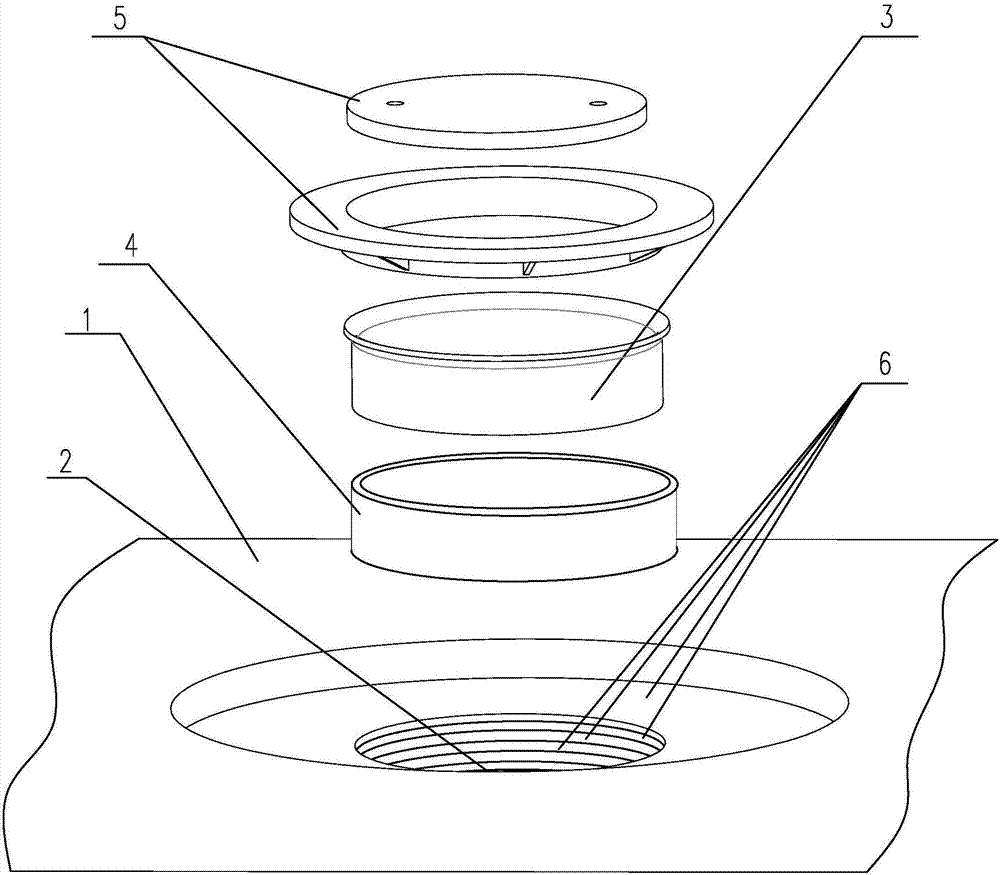

[0021] Depend on figure 1 It can be seen that the present invention discloses a method for manhole cover construction and installation, comprising the following steps

[0022] Step 1, the peripheral treatment of the well circle, draw the breaking range on the road surface 1 with the center of the well circle 2 as the center, the radius of the breaking range is obtained by adding the radius of the well circle 2 and the width of the working face of the rammer, and the working face of the rammer is ring-shaped, The impact rammer is used to break the road surface within the demolition range. First, determine the demolition range to facilitate the backhoe loader to work, effectively reduce the damage to the original road surface, and effectively improve the follow-up construction efficiency. The width of the rammer working surface is usually 30cm to ensure the quality of the impact rammer. At the same time, effectively protect other road surfaces;

[0023] Step 2: Perform balance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com