Automatic driving luggage trailer for airports

An automatic driving and airport technology, applied in the field of aviation, can solve problems such as dangerous driving, prone to blind spots, fatigue driving, etc., and achieve the effect of safe and efficient driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

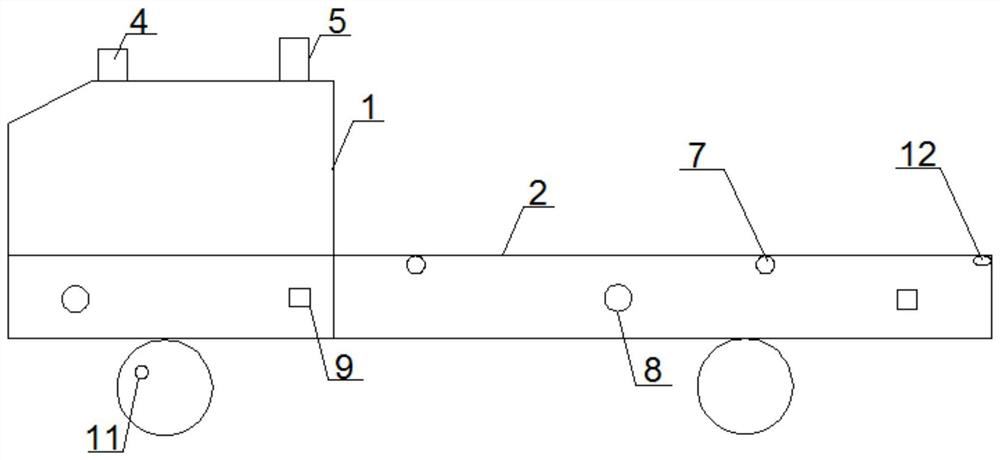

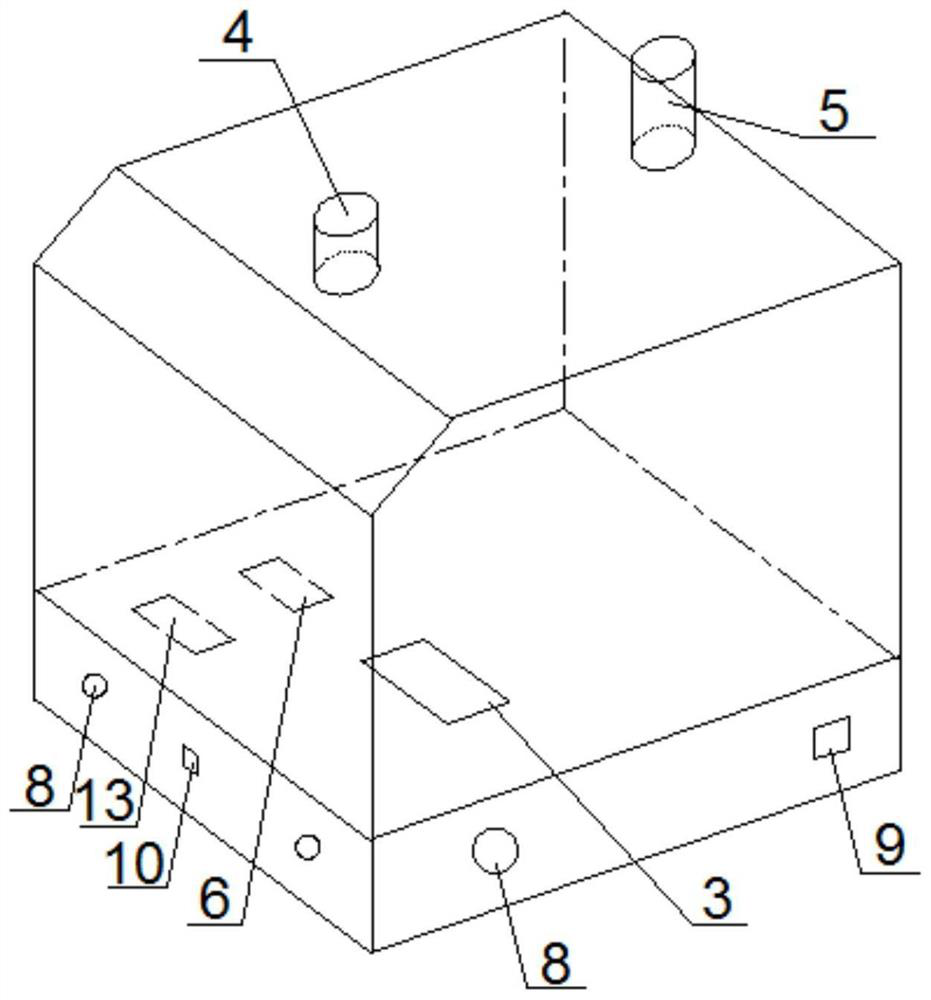

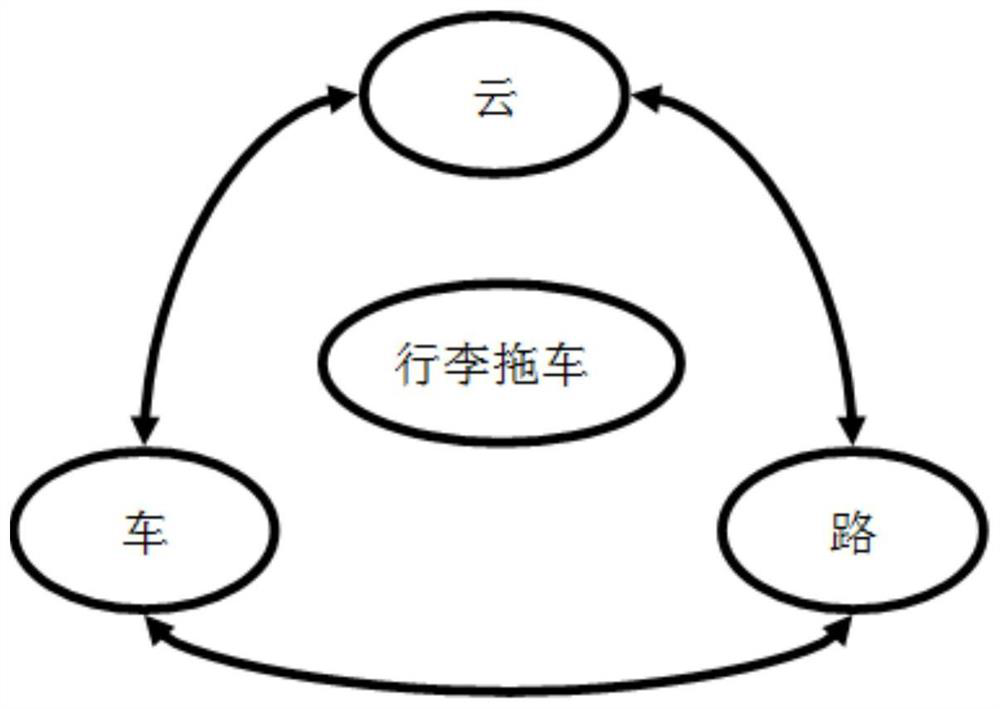

[0024] See Figure 1 to Figure 3 , is a self-driving luggage trailer for airports provided by an embodiment of the present invention, which can interact with the host system in the airport and can complete corresponding tasks under the instructions of the host system. The self-driving luggage trailer includes a head 1, wheels and at least one pallet 2. The head 1 is provided with a control module 3 that interacts with the host system in the airport. The top of the head 1 is provided with a main laser radar 4 and a The height detector 5 that is used for height limit, is all provided with weight detector 7 on every joint pallet 2. Specifically, the altitude detector 5 is an infrared superelevation detector.

[0025] During use, the control module 3 needs to interact with the upper system throughout the process, obtain the route and road information planned by the upper system, and control the automatic driving luggage trailer to move forward and perform related tasks based on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com