Dual lens measurement system

A measurement system and dual-lens technology, applied in the field of measurement systems, can solve problems such as inability to meet the needs of tool design and manufacturing industries, inability to detect accurate data, limited measurement functions and precision, etc., to avoid repeated positioning errors and improve quality stability and consistency, improving measurement accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

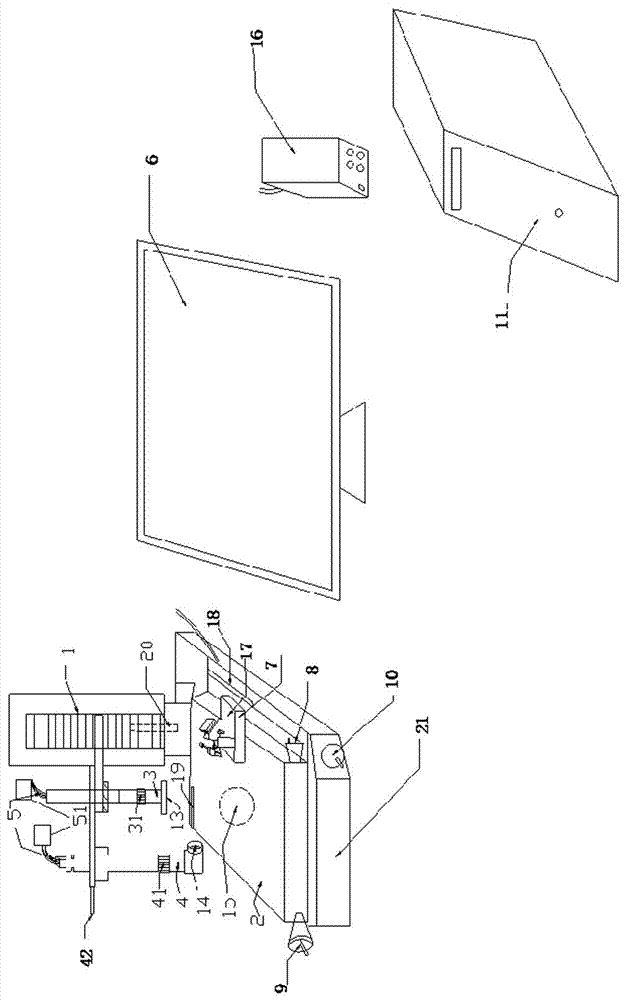

[0016] see figure 1 , the present invention adopts the following technical solutions: including base 21, frame 1, worktable moving mechanism 2, measuring mechanism, vertical lens 3, horizontal lens 4, camera 51, image processing unit 11, cable 5, display 6 and Measuring fixture 7; the workbench moving mechanism 2 is arranged on the base 21, the measuring fixture 7 is arranged on the workbench moving mechanism 2, and the vertical lens 3 and the horizontal lens 4 are all located on the frame 1, so Both the vertical lens 3 and the horizontal lens 4 are provided with focal length zoom adjusters (31, 41), the vertical light source 13 is arranged on the vertical lens 3; the horizontal light source 14 is arranged on the horizontal lens 4 The backlight light source 15 is located on the workbench moving mechanism 2; the horizontal lens 4 is provided with an angle rotation device 42 that can rotate the horizontal lens 4 along the axis of the vertical lens 3 above the horizontal lens 4; ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap