High-flux large-aperture high-precision wedge-shaped lens focusing device and five degrees-of-freedom adjustment method

A large-diameter, high-throughput technology, applied in installation, optics, instruments, etc., to avoid online optical adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

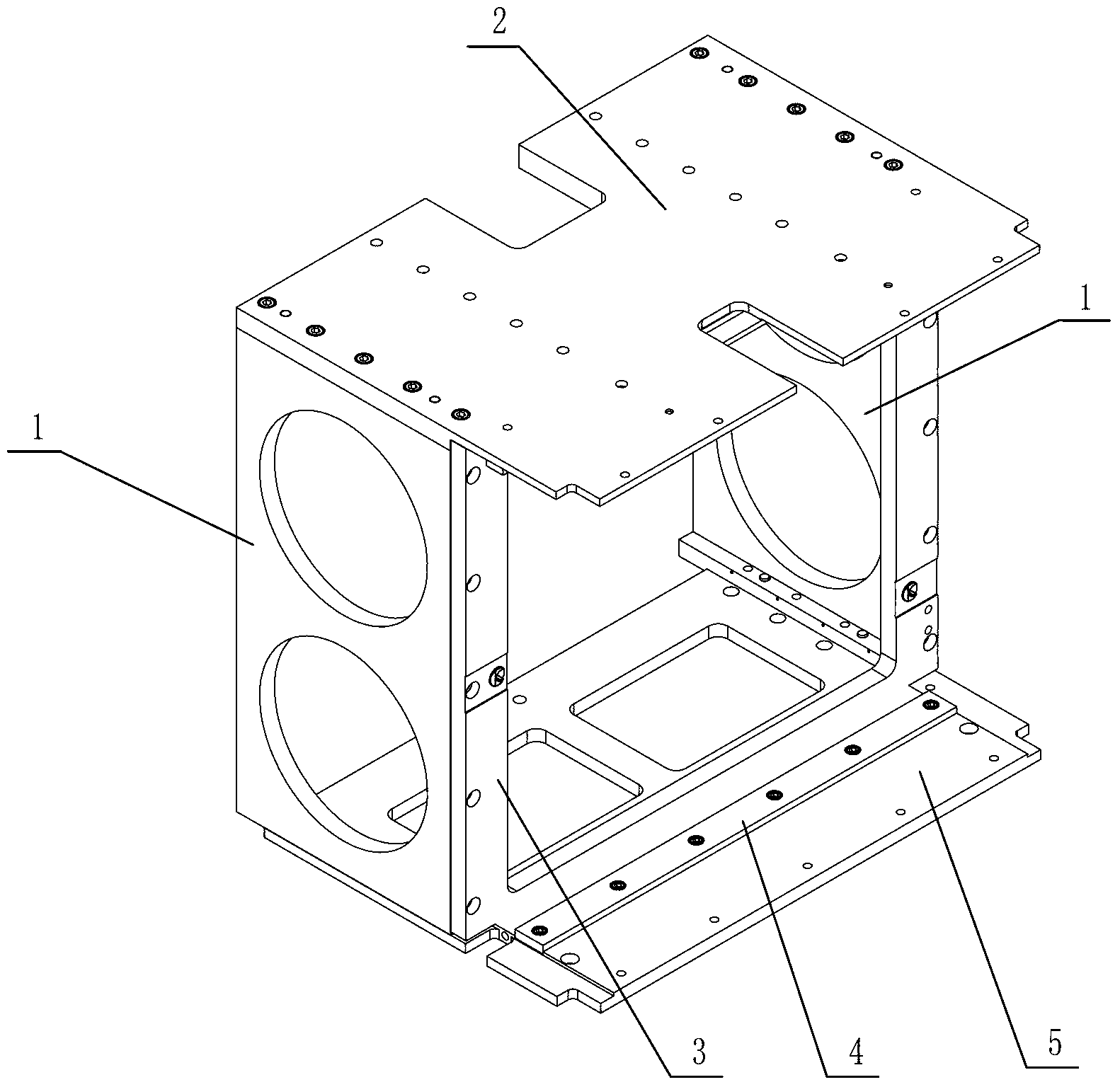

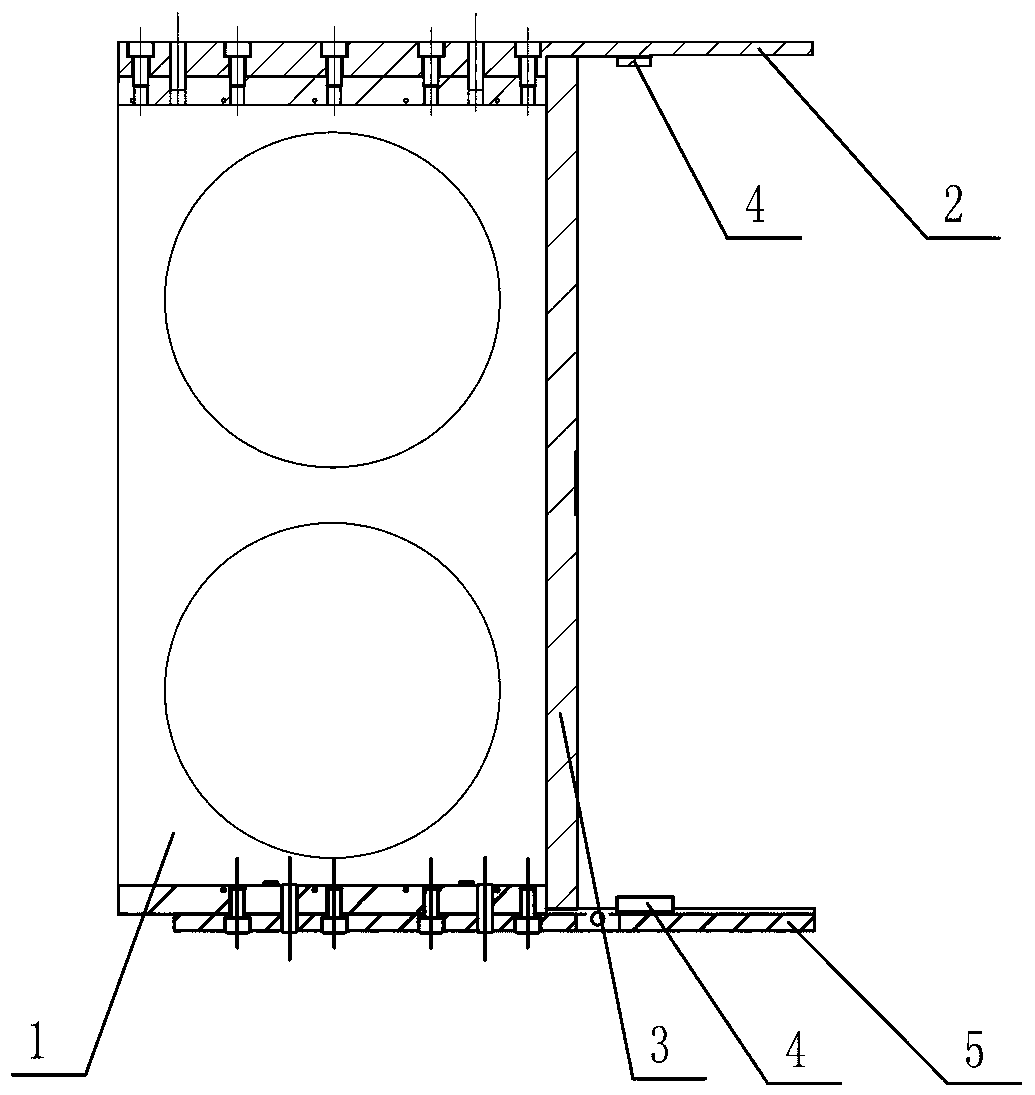

[0063] Specific implementation mode one: combine Figure 1 to Figure 37 Describe this embodiment. The high-throughput, large-aperture, and high-precision wedge lens focusing device of this embodiment includes a lens squirrel cage front support adjustment assembly A, a lens module mechanism Q, a lens squirrel cage rear support adjustment assembly B, and a focus lens module housing C, the lens module mechanism Q includes a squirrel cage mechanism D, a lens focusing moving part E, a wedge lens part F, an upper rail part G, a lower rail part H, a beam sampling grating I, a beam shaping element J and a lens focusing drive Institution K;

[0064] The wedge lens part F, the beam sampling grating I and the beam shaping element J are installed on the lens focusing moving part E, the lens focusing driving mechanism K is installed on the lens focusing moving part E, the lens focusing moving part E, the wedge lens part F. The beam sampling grating I, the beam shaping element J and the le...

specific Embodiment approach 2

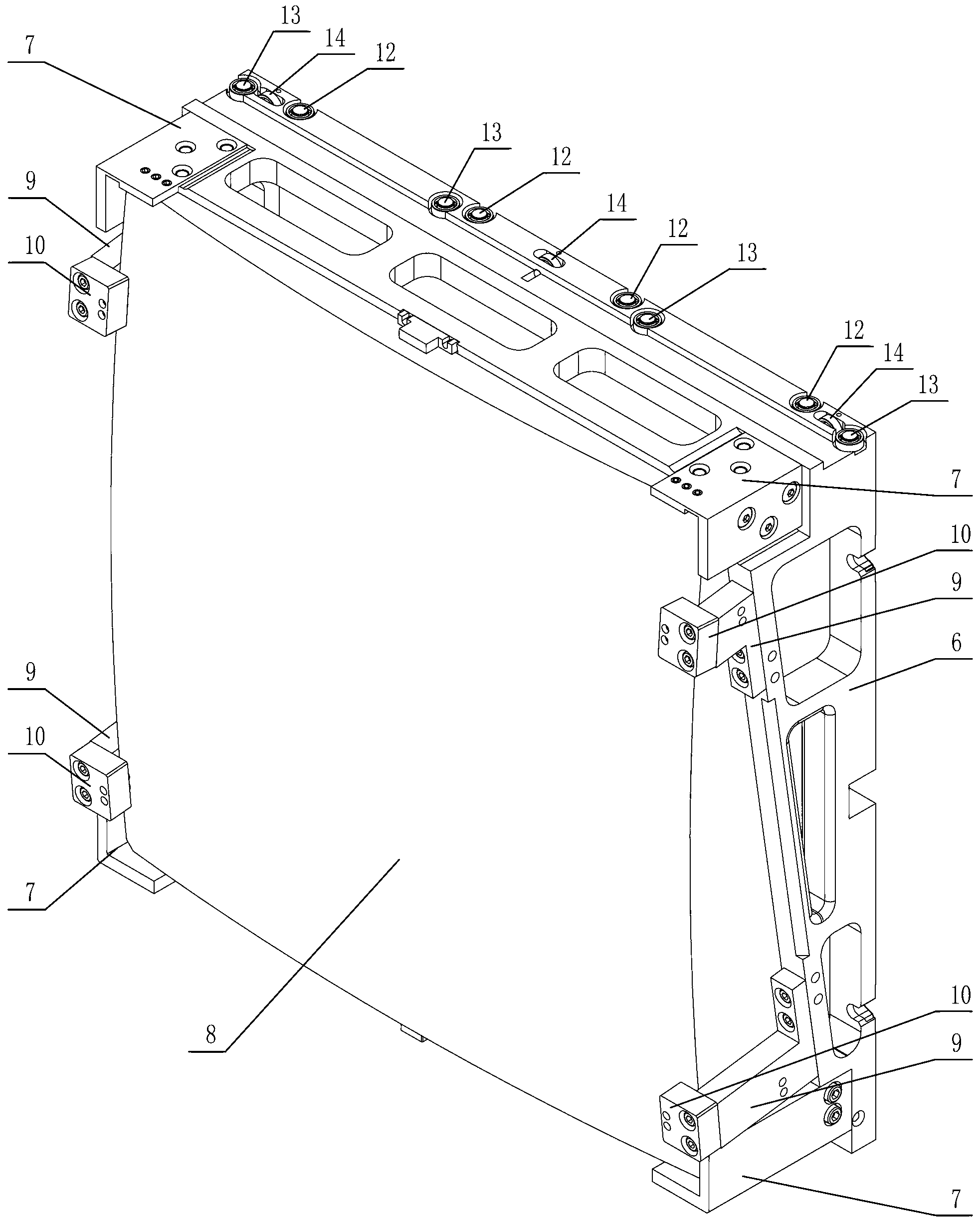

[0077] Specific implementation mode two: combination image 3 , Figure 4 , Figure 6 , Figure 10 and Figure 12 To illustrate this embodiment, the first lens assembly disassembly guide bearing group of this embodiment includes a plurality of first guide bearings 12, a plurality of second guide bearings 13 and a plurality of third guide bearings 14, and a plurality of first guide bearings 12 , a plurality of second guide bearings 13 and a plurality of third guide bearings 14 are all arranged on the upper side of the wedge-shaped lens positioning frame 6, wherein a plurality of first guide bearings 12 are used to move the frame with the lens in the moving frame assembly The front end of the fitting 3 is frictionally guided on the contact surface, and a plurality of second guide bearings 13 are used for friction guidance on the rear side contact surface of the focusing lens guide plate 4 on the lens moving frame top plate 2 in the moving frame assembly. The guide bearing 14...

specific Embodiment approach 3

[0082] Specific implementation mode three: combination image 3 , Figure 4 , Figure 6 , Figure 10 and Figure 12 To describe this embodiment, each guide bearing in the detachable guide bearing group of the first lens assembly of this embodiment is a deep groove ball bearing. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com