True three-dimensional mining blast unit body modeling method

A blasting unit and model building technology, applied in 3D modeling, image data processing, special data processing applications, etc., can solve problems such as high error rate, inaccurate two-dimensional model, and extensive blasting unit management, and achieve accurate Improved performance, simple and convenient technical means, and scientific resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

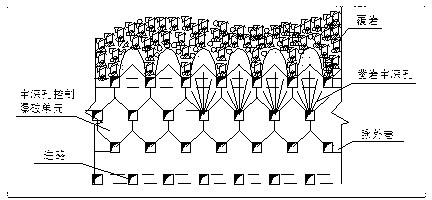

[0043] The mining method of segmental caving without pillars is adopted, and the design parameters of the stope are: the segmental height is 15 meters, and the approach distance is 20 meters. The ore body is in a north-south direction, with a length of about 800 meters from north to south and a width of about 500 meters from east to west. The azimuth of the ore body is 20° from north to east.

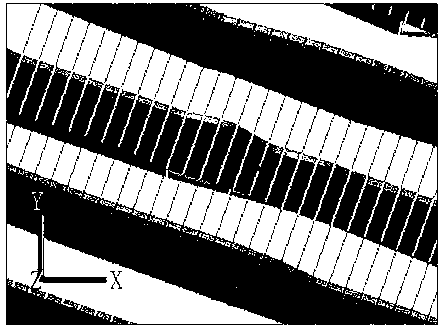

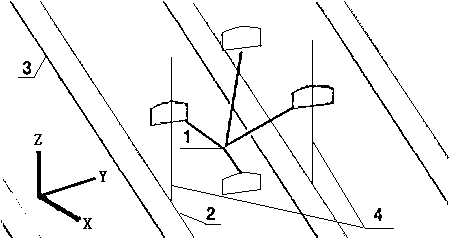

[0044] According to the above-mentioned design parameters, use software to generate the stope and each stratified recovery approach contour line 1 . The present invention is preferably completed by secondary development of the professional three-dimensional digital mining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com