Upright piano action bushing processing method and device

A technology for upright pianos and action machines, applied in stringed instruments, bearing components, shafts and bearings, etc., can solve problems such as difficult to achieve and difficult to ensure long-term lubrication stability, and achieve flexibility without decreasing, avoiding smooth operation, Stress-reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

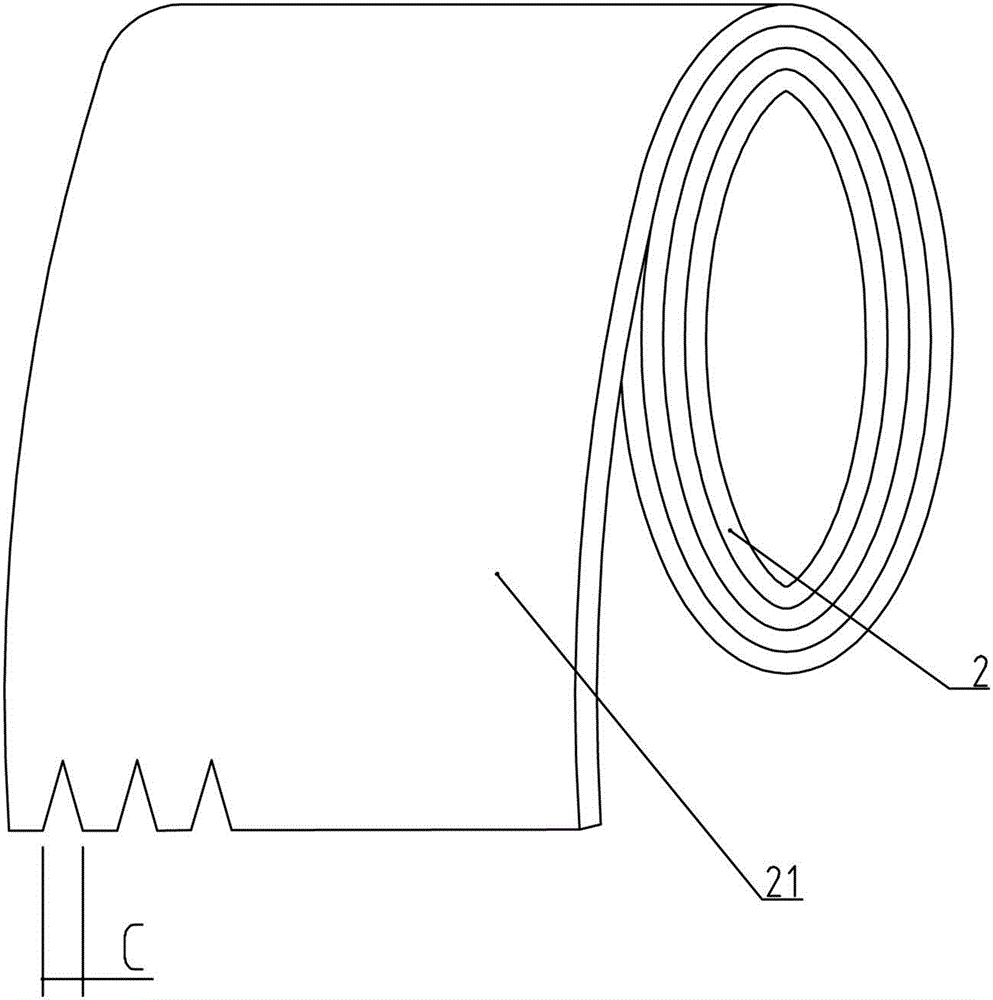

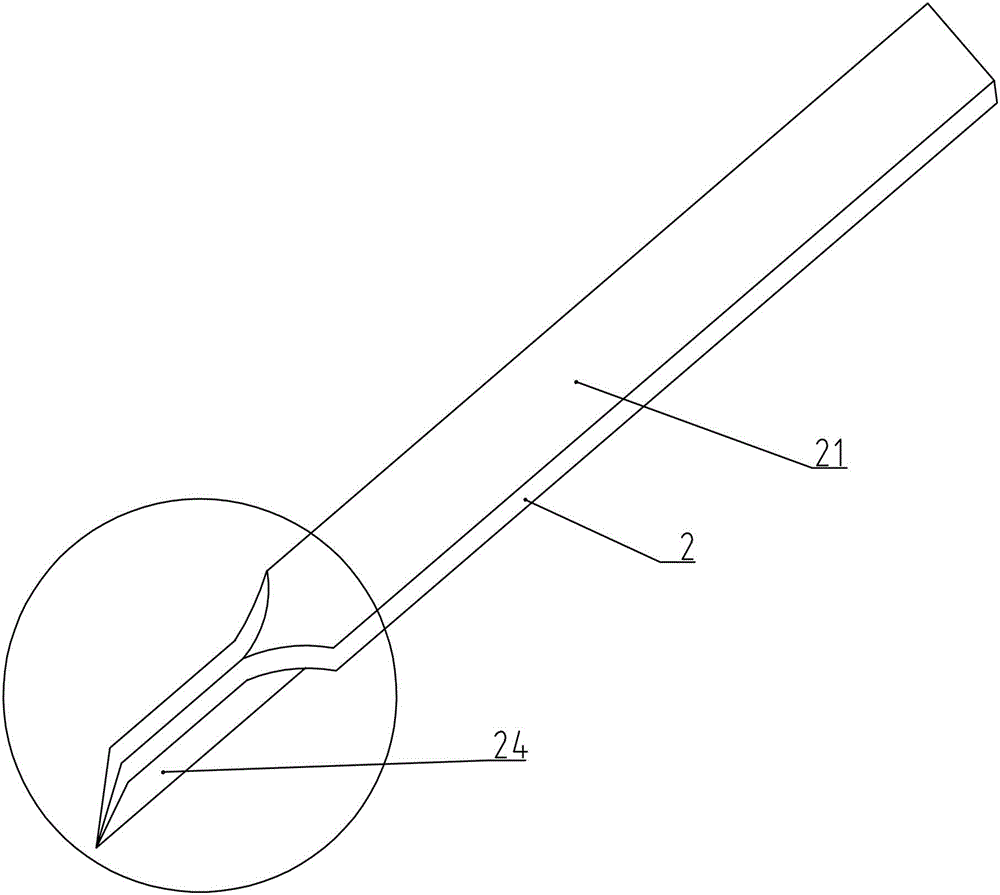

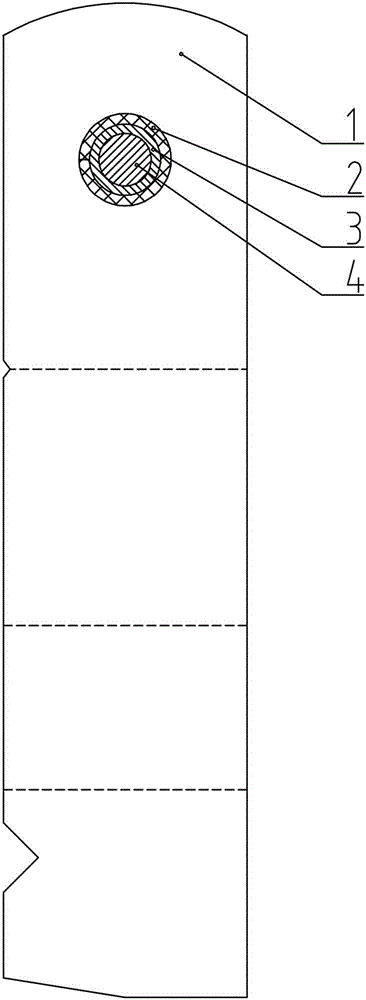

[0035] Such as image 3 Among them, a bushing device for an upright piano action, including a shaft frame 1, a shaft nail hole is provided on the shaft frame 1, and a shaft nail 4 is installed in the shaft nail hole, and the shaft nail 4 and the inner wall of the shaft nail hole A bushing 2 is arranged between them, and the surface of the bushing 2 in contact with the shaft nail 4 is a graphite coating layer 21 , and the surface of the bushing 2 in contact with the shaft nail hole is a glue coating surface 22 .

[0036] A lead powder layer 3 is also provided between the bushing 2 and the shaft nail 4 .

[0037] The bushing closing position 23 of the bushing 2 is toward the side of the notch 11 of the shaft frame. This structure ensures that the stress structure of the bushing 2 is more reliable.

[0038] Such as Figure 1-7 Among them, a method for processing the above-mentioned upright piano action bushing device, comprising the following steps:

[0039] 1. The graphite c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com