Noise power generating device based on micro-perforated panel structure

A technology of micro-perforated plates and noise power generation, which is applied in the direction of electrical components, generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., and can solve problems such as failure to take into account sound absorption and noise reduction, To achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

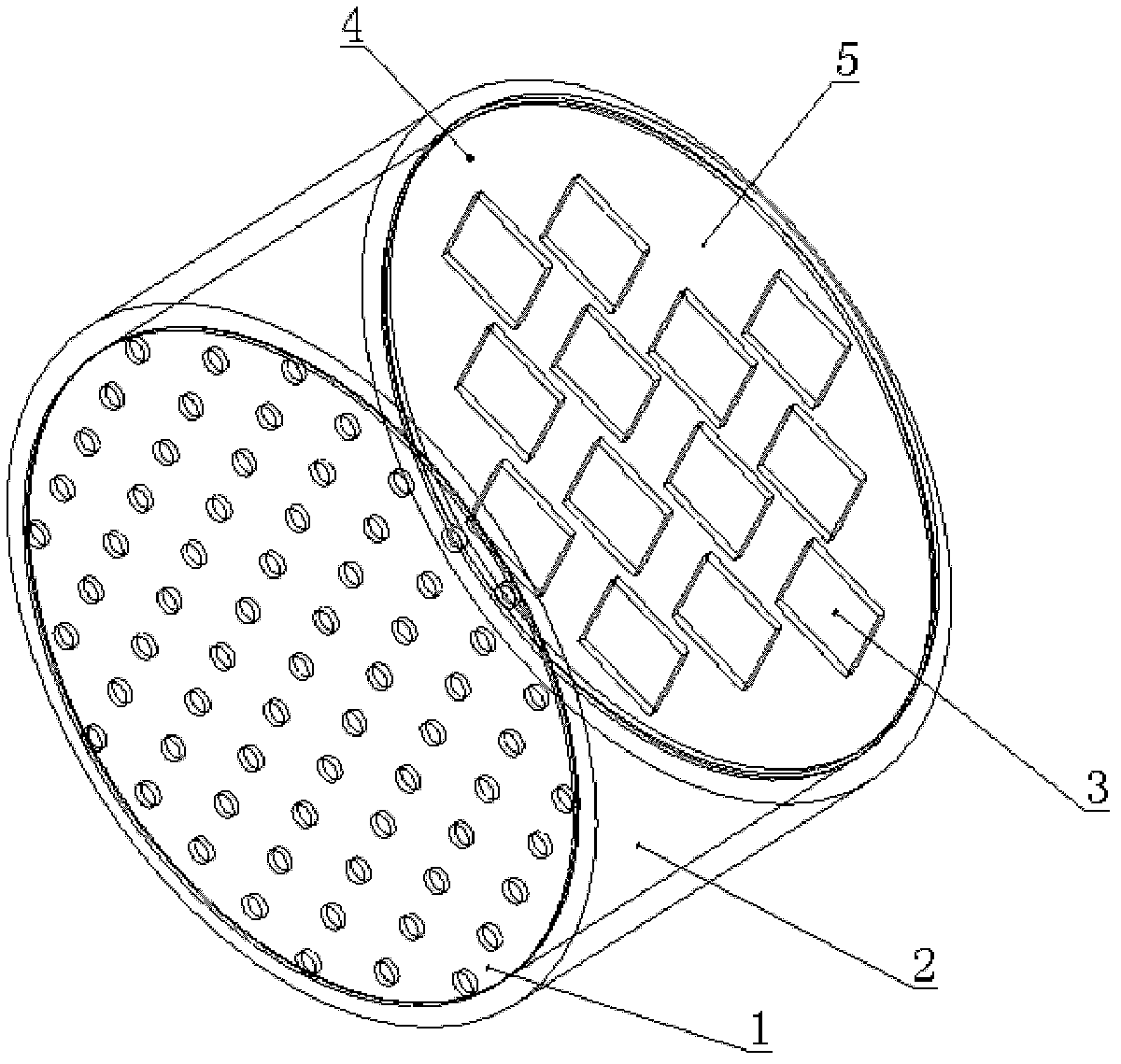

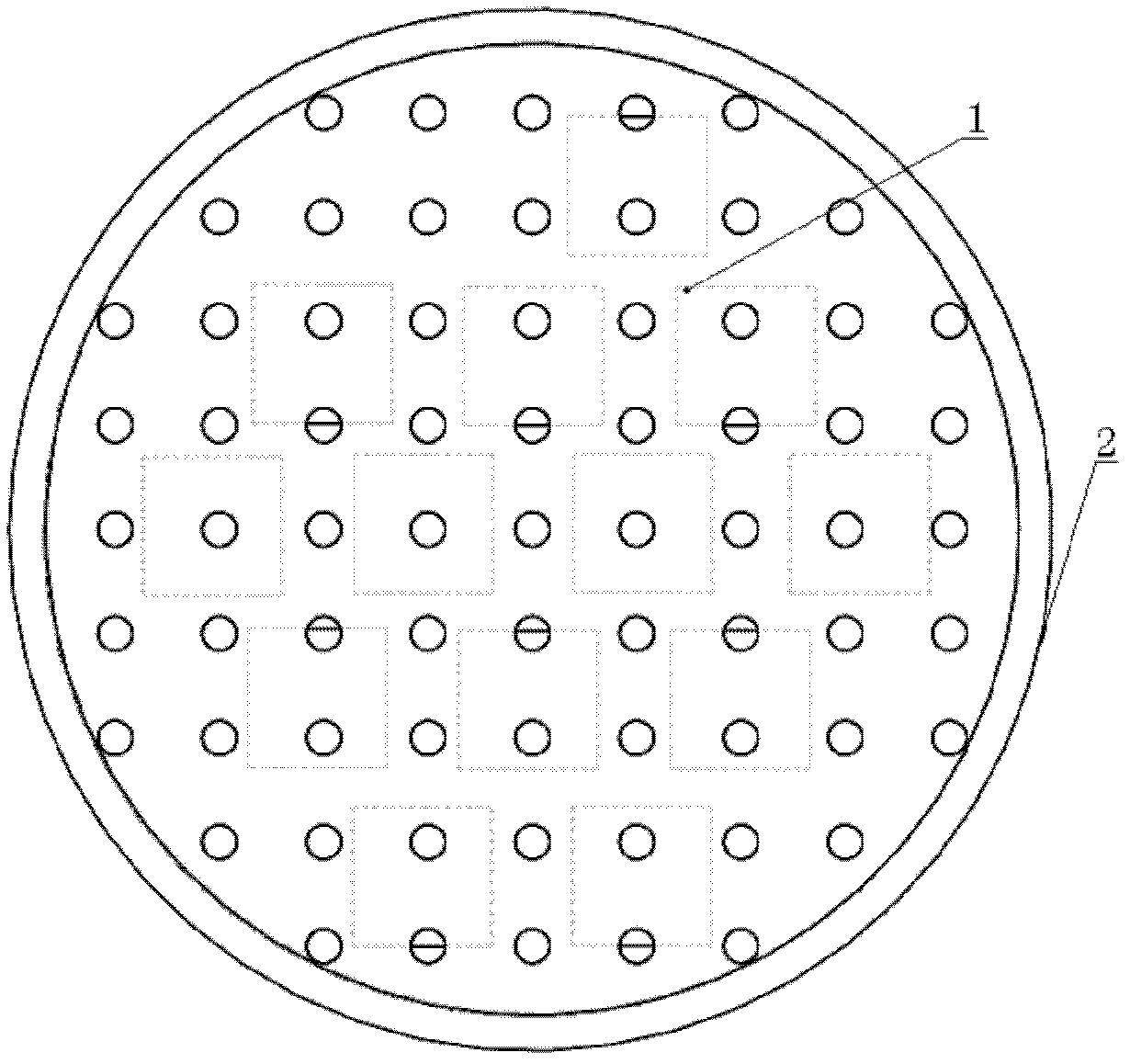

[0023] A noise power generation device based on the micro-perforated plate structure of the present invention: the sound enters the resonant cavity through the micro-perforated plate, causing the air in the cavity to vibrate and reduce the external sound energy reflection; at the same time, the vibrating air in the cavity causes sensitive piezoelectricity on the bottom plate. The vibration of the film generates polarized charges, which are collected from the surface of the piezoelectric film through the upper and lower electrodes. The specific principles are as follows:

[0024] The small hole is regarded as a thin tube, and a pressure difference is added between the two ends of the tube to cause the gas flow in the tube. According to the formula of the acoustic impedance rate of the small tube, it can be obtained

[0025] Z = ΔP u ‾ = jωρt [ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com