Nonlinear rheology of chewing gum and gum base

A technology of chewing gum and rheology, which is applied in the field of nonlinear rheology test of chewing gum and gum base, which can solve the problems of insufficient description of deformation and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

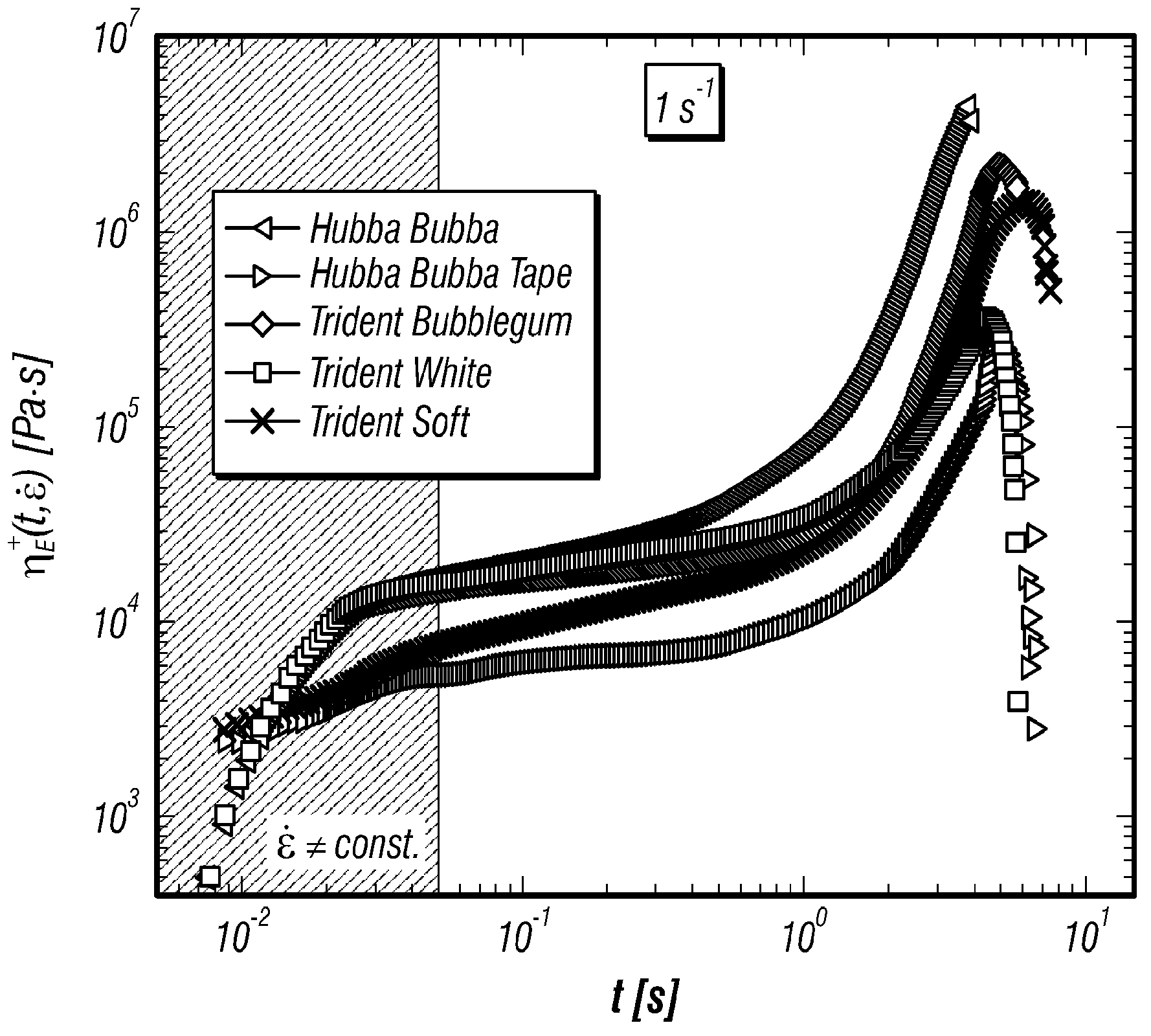

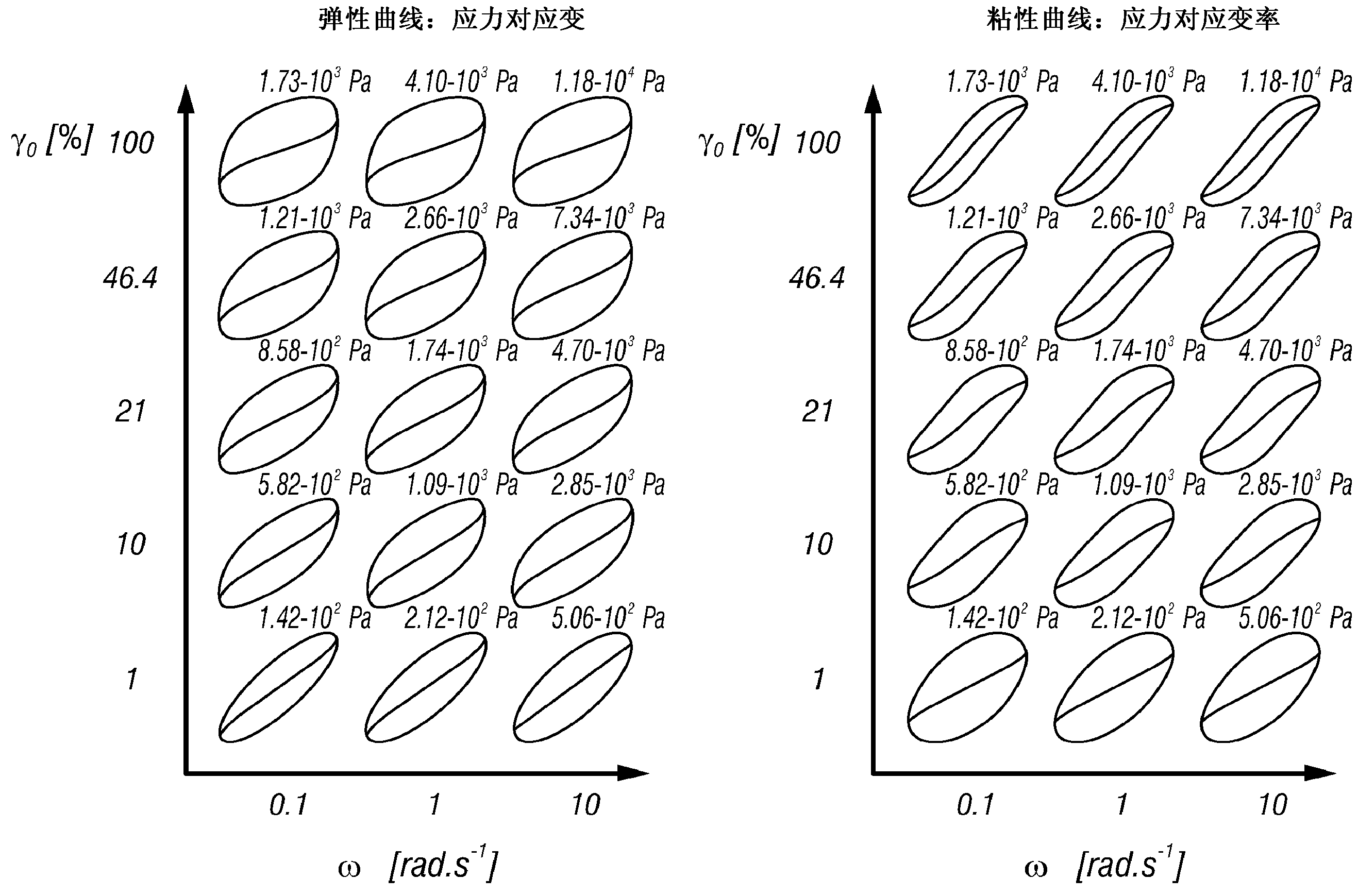

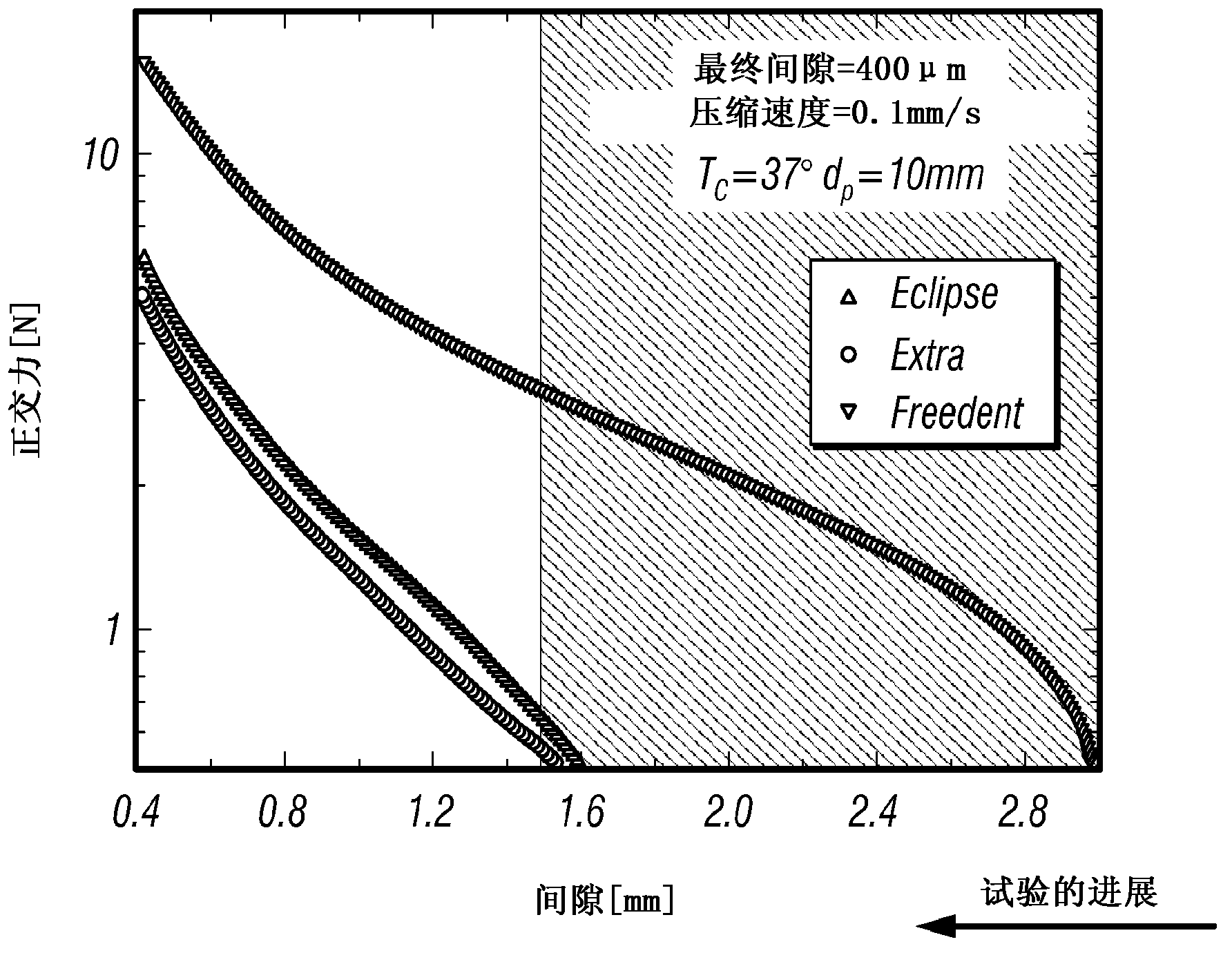

[0017] Chewing gum provides an excellent everyday example of viscoelastic behavior. It flows when chewed or slowly pulled between the fingers, the internal stress persists after deformation ceases, and it retracts after the externally imposed stress is suddenly relieved. It also breaks when blown into a bubble or pulled quickly. Therefore, understanding the rheological properties of chewing gum is important for application and processing purposes. Chewing behavior includes nonlinear large, complex and unstable deformations from closed phase, sliding phase to open phase. The closed phase can be associated with biaxial tension or uniaxial compression. The sliding phase can be associated with a large amplitude oscillatory shear test (LAOS), and the open phase can be associated with initiating flow in uniaxial tension.

[0018] The present invention provides a method for selecting commercially viable chewing gums using nonlinear rheology testing. The nonlinear rheological test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com