Finish-milling clamp suitable for top surface of inclined cylinder head

An engine cylinder head and top surface technology, applied in clamping, manufacturing tools, metal processing mechanical parts, etc., can solve problems such as the influence of cylinder head processing efficiency, the decline of cylinder head yield, and the large flatness of the positioning surface. The problem of angle adjustment, the improvement of clamping efficiency and the effect of high clamping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

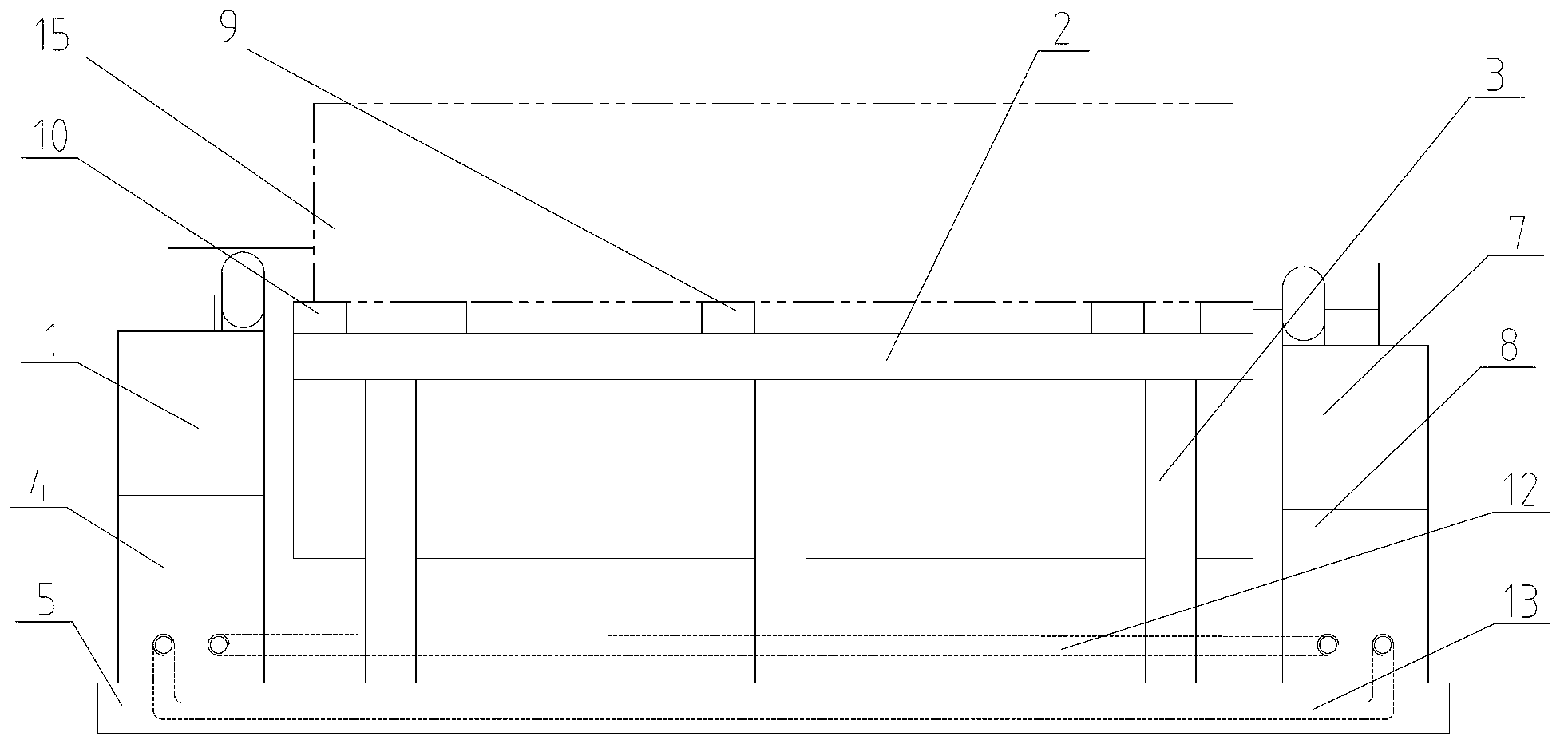

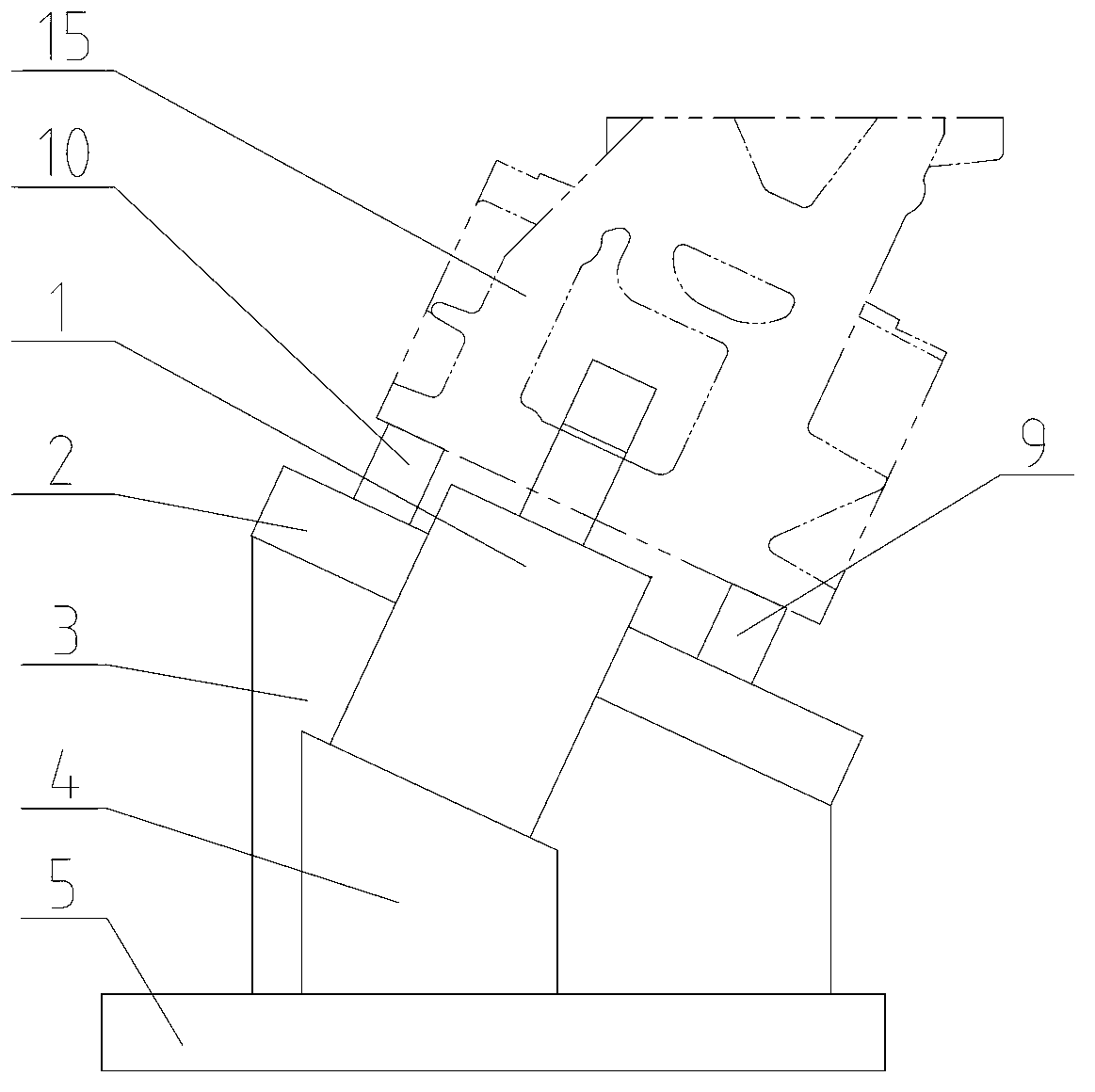

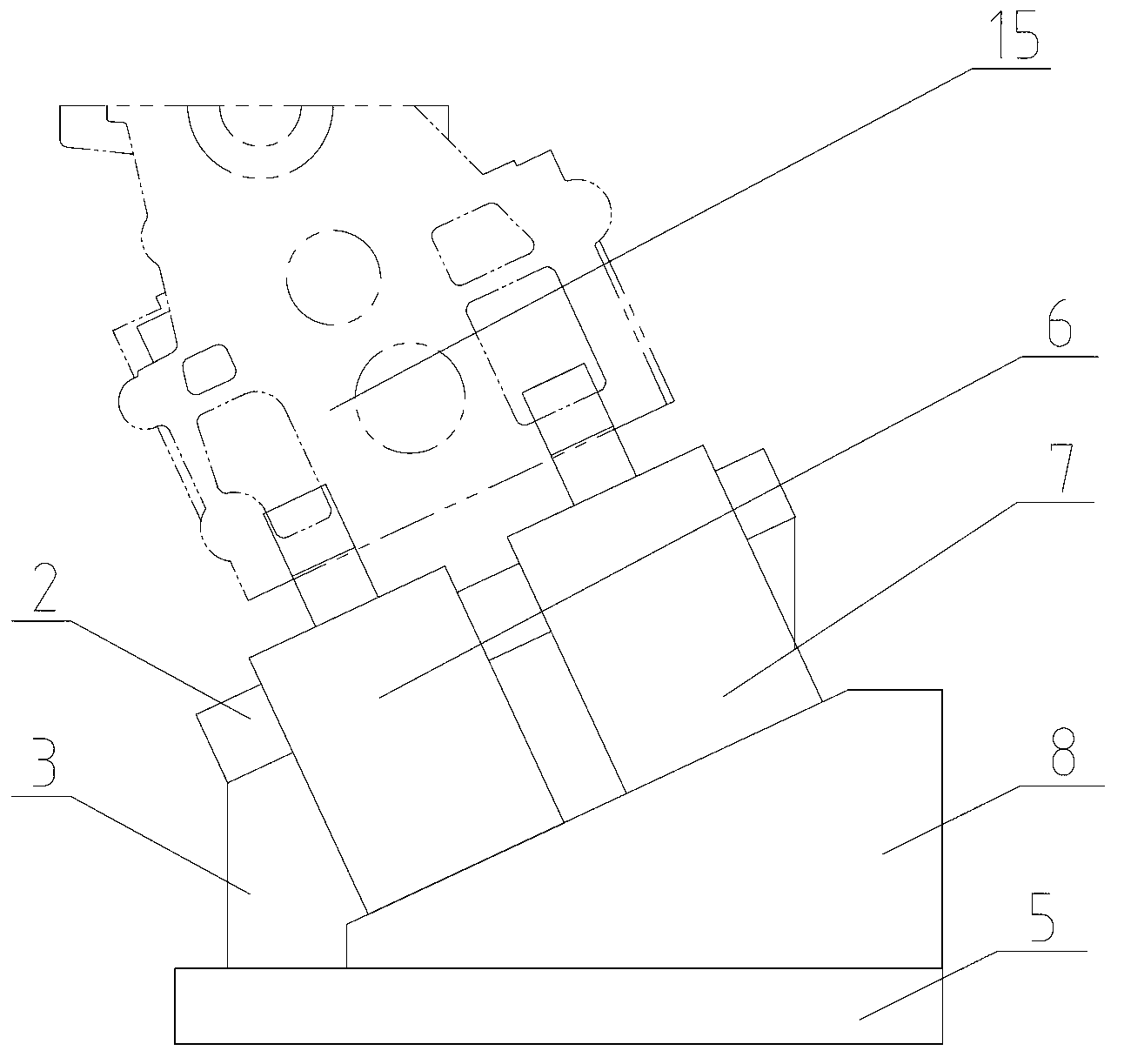

[0017] Such as figure 1 , figure 2 , image 3 with Figure 4 Shown is a top finish milling jig suitable for a sloped engine cylinder head according to the present invention, which includes a base for placing the cylinder head 15 and a press for fixing the cylinder head 15 on the base. Tightening mechanism, the base includes a locating plate 2 which is arranged obliquely, and the cylinder head 15 is positioned on the positioning mechanism provided on the locating plate 2 with its bottom surface. The positioning mechanism forms an inclined surface with the same inclination angle as the top surface of the cylinder head 15. After the cylinder head 15 is clamped, the top surface of the cylinder head 15 is parallel to the horizontal direction. Compared with the prior art, this jig for fine milling the top surface of the cylinder head is made so that the installation position of the cylinder head is consistent with the angle of the top surface of the cylinder head, so that the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com