Existing line protective shed

A technology with existing lines and protective sheds, applied in the field of protective sheds, can solve the problems of inconvenient dismantling, the strength and stability of the protective shed supports cannot meet the requirements of use, etc., and achieve the effects of good wind and vibration resistance, satisfying protection, and accelerating construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 is cross-railway protective shed:

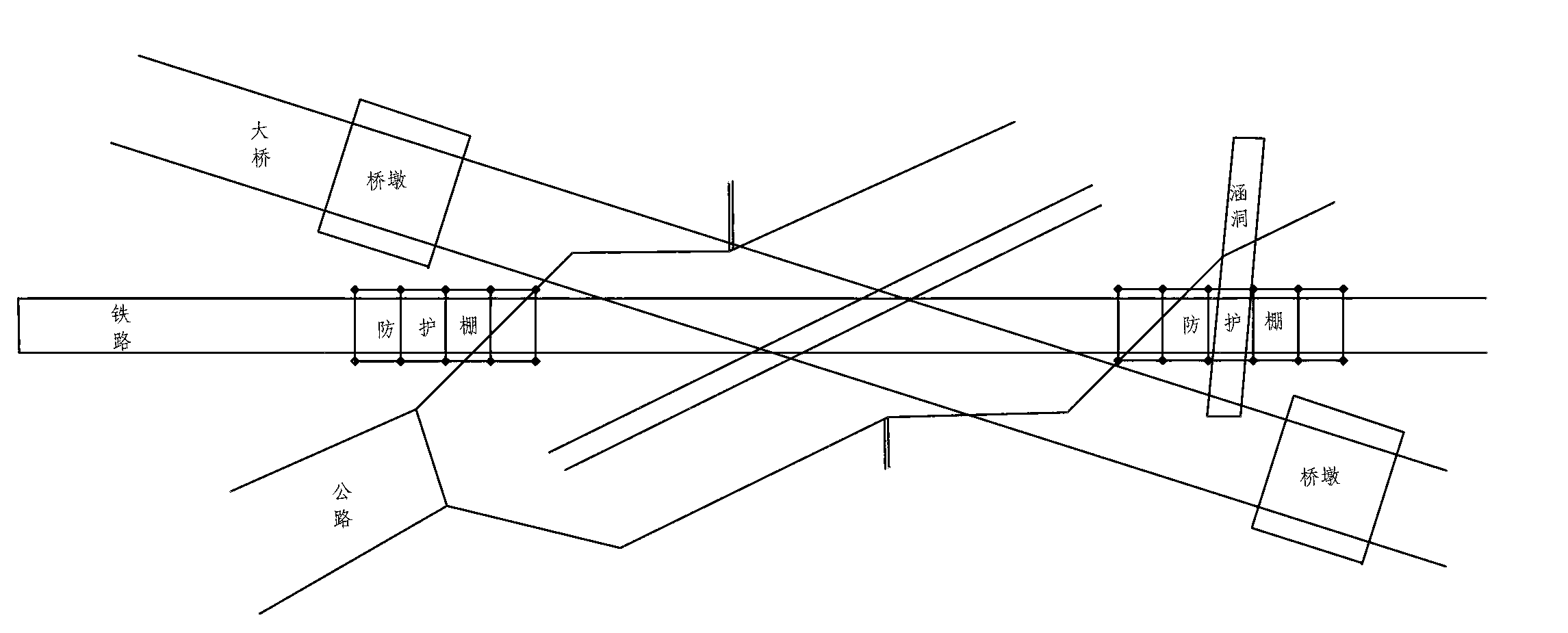

[0037] Such as figure 1 Shown is the layout of the bridge, existing railway lines, existing highway lines, and protective sheds. In order to ensure the normal and safe operation of the railway during the construction period, protective sheds must be erected on both sides of the road beams 30 meters away from the major and minor mileages of the railway. The protective shed adopts one span across the existing railway line, obliquely intersects with the existing highway line, the angle of intersection is 45°, and the span is 13.5m.

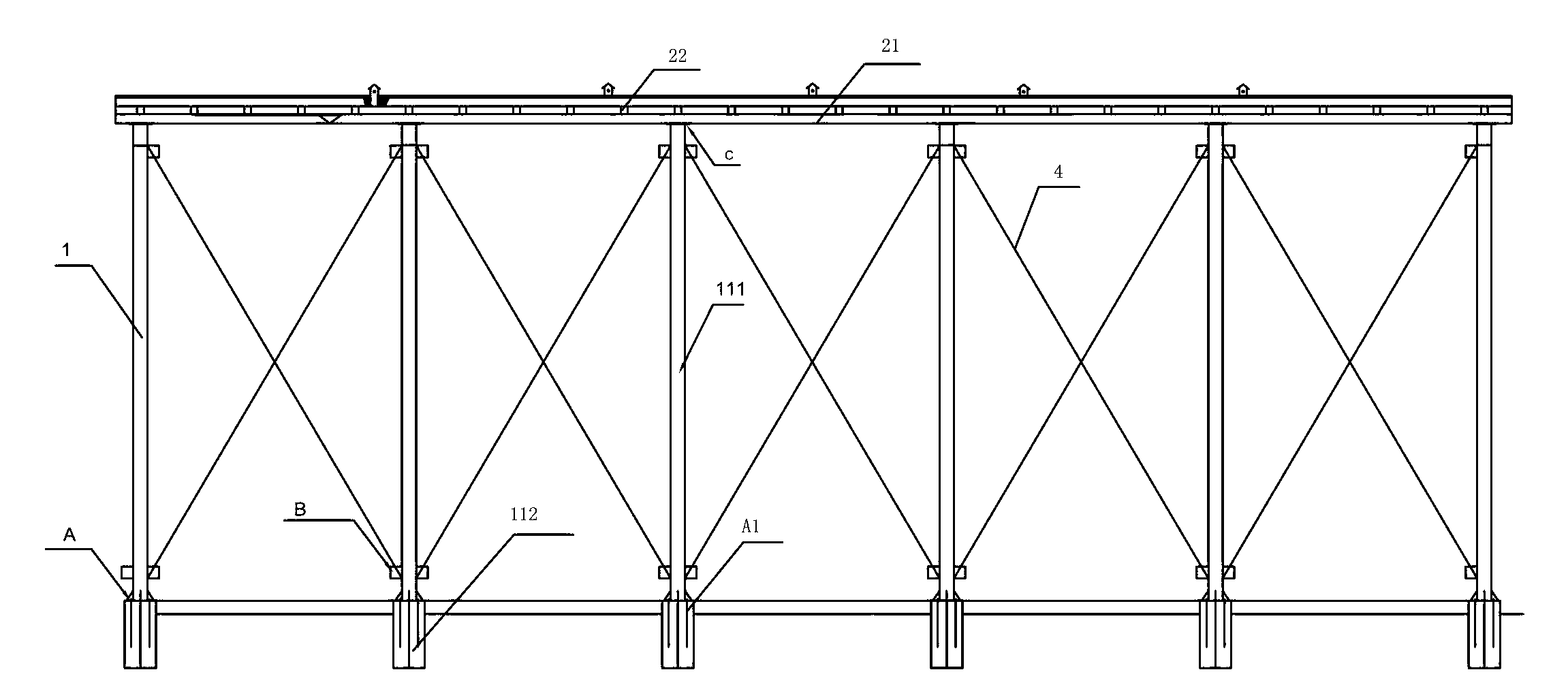

[0038] In order to meet the horizontal and vertical stability of the protective shed, the number of supporting columns on one side of the railway is 6, the spacing is 6M, and the height is 10.66m.

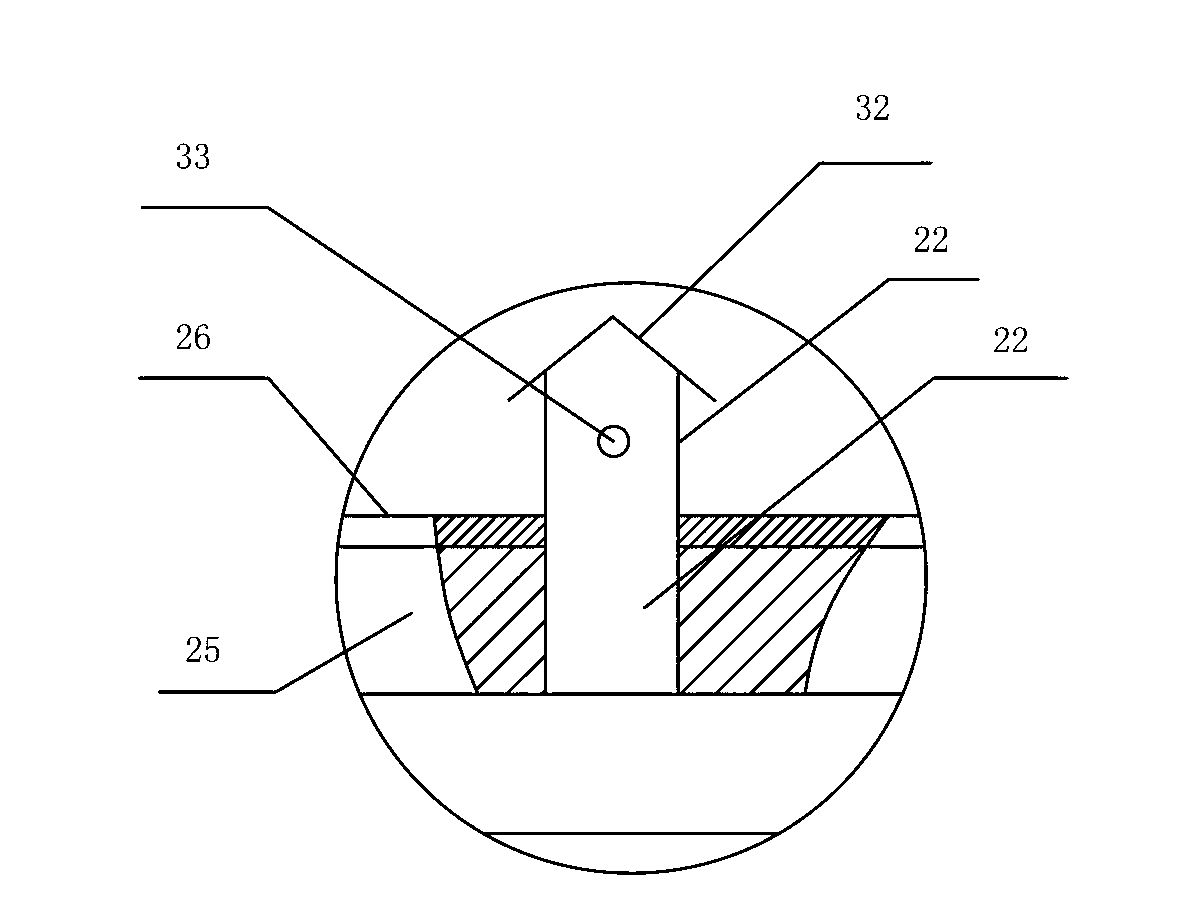

[0039] In order to meet the electrical insulation of the protective shed, the hoisting units that make up the roof include iron sheets, wooden boards, insulating boards, and beams 22 from top to bot...

Embodiment 2

[0085] Embodiment 2 is cross-highway protective shed:

[0086] Figure 4 It is the layout diagram of the bridge, the existing road, and the protective shed. In order to ensure the normal and safe operation of the road during the construction period, a protective shed must be set up under the bridge. Set the width to 12m, and set the width to 16m on the right. In order to ensure the clearance requirements for highway driving, the minimum height from the protective shed to the road surface is 5m, and the protection scheme is as follows:

[0087] The number of support units is 3, and the outer support units are arranged on both sides of the road. In order to meet the horizontal and vertical stability of the shelter, the number of support columns for each support unit is 5, with a height of 3.7m and a spacing of 6m.

[0088] In order to meet the strength requirements of the protective shed, the longitudinal beams are made of 20b double-channel steel, the beams are 18b double-cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com