Gas content spot sampling method and device

A fixed-point sampling and gas content technology, applied in sampling devices, buildings, etc., can solve problems such as difficulty in meeting the sanitation standards of the working environment, high gas concentration in the jet airflow, and no fixed-point sampling tools, etc., to improve the effect of ventilation and dust removal, and easily The effect of processing and manufacturing to ensure the health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

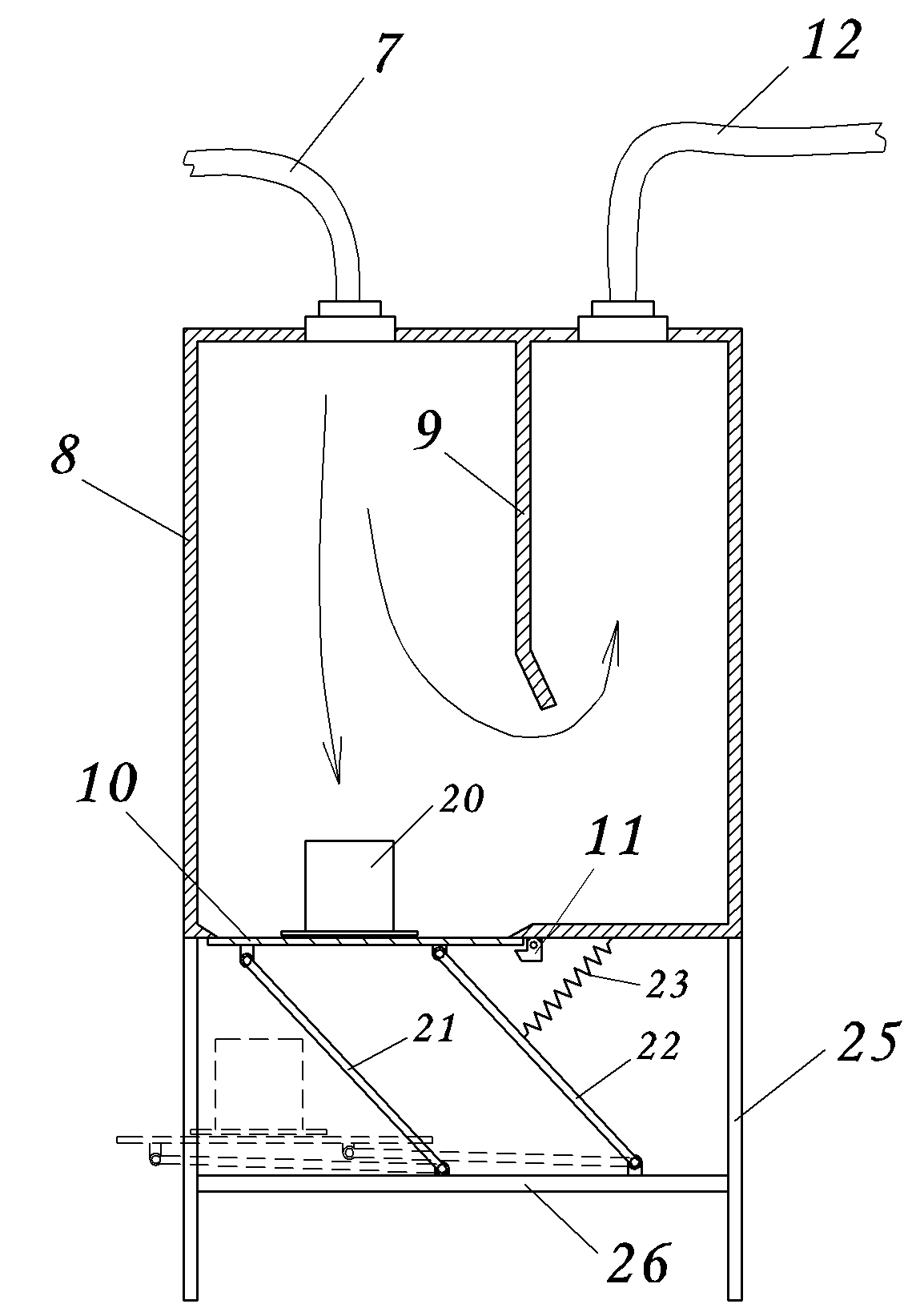

[0023] Embodiment 1: A fixed-point sampling method for gas content, using a hydraulic drilling rig to drill a hollow drill rod with a hollow drill bit into the depth of the coal seam, and using an exhaust mechanism to continuously pump air to the hollow drill rod, not only setting a suction port in the hollow drill bit, but also On the hollow drill rod, the rear side of the hollow drill bit is uniformly provided with air suction ports, and a wing plate parallel to the axial direction is also provided between the hollow drill bit and the air suction ports. During the ventilation process, the air and coal seam particles passing through the hollow drill pipe are connected to the ventilation mechanism after passing through a ventilation box. The ventilation box is divided into a particle deposition chamber and a ventilation chamber, and the bottom of the two is connected. Evacuate and seal all the coal seam particles in the air suction box, and analyze the coal seam by using the co...

Embodiment 2

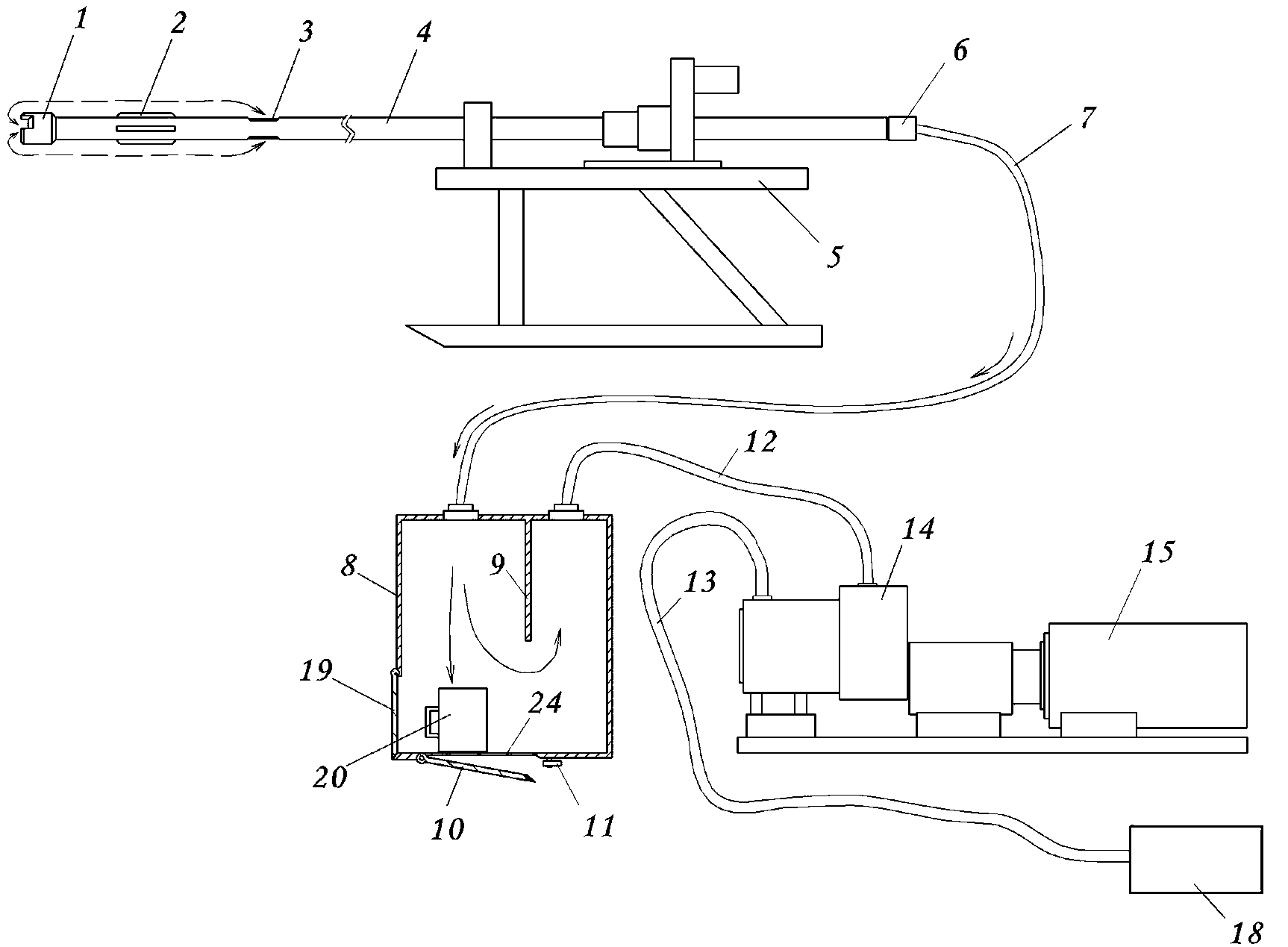

[0024] Example 2: see figure 1 , a fixed-point sampling device for gas content, consisting of a hollow drill pipe 4, a hollow drill bit 1, a hydraulic drilling rig and a support 5, an exhaust mechanism and a drainage system 18, and the like. Wherein, the hollow drill rod 4 is horizontally installed on the support and connected with the hydraulic drilling rig in transmission. The hollow drill bit 1 is installed on the front end of the hollow drill rod 4, and an air extraction port is arranged in the hollow drill bit. At the same time, an air extraction port 3 is arranged on the side wall of the front section of the hollow drill rod 4 (located at the rear side of the hollow drill bit). A section of the hollow drill pipe side wall between the gas ports 3 is evenly provided with a plurality of flaps 2, the flaps 2 are parallel to the axis and have a certain length, and the flaps 2 can also be arranged in a staggered front and rear or in a staggered manner. The wing plate 2 plays ...

Embodiment 3

[0028] Embodiment 3: The accompanying drawings are not drawn, and the content is basically the same as that of Embodiment 2, and the similarities will not be repeated. The difference is that the door of the side wall at the bottom of the suction box is hinged to the side wall of the suction box, and is fixed to the grille Together they form a pull-out structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com