Negative pressure drilling system to prevent gas overrun

A negative pressure and gas technology, which is applied in the field of special air suction drills for coal mines, can solve the problems of difficulty in meeting the sanitation standards of the working environment, high gas concentration in the jet stream, and ineffective implementation, and achieve improved ventilation and dust removal effects, easy processing and manufacturing, The effect of ensuring the health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

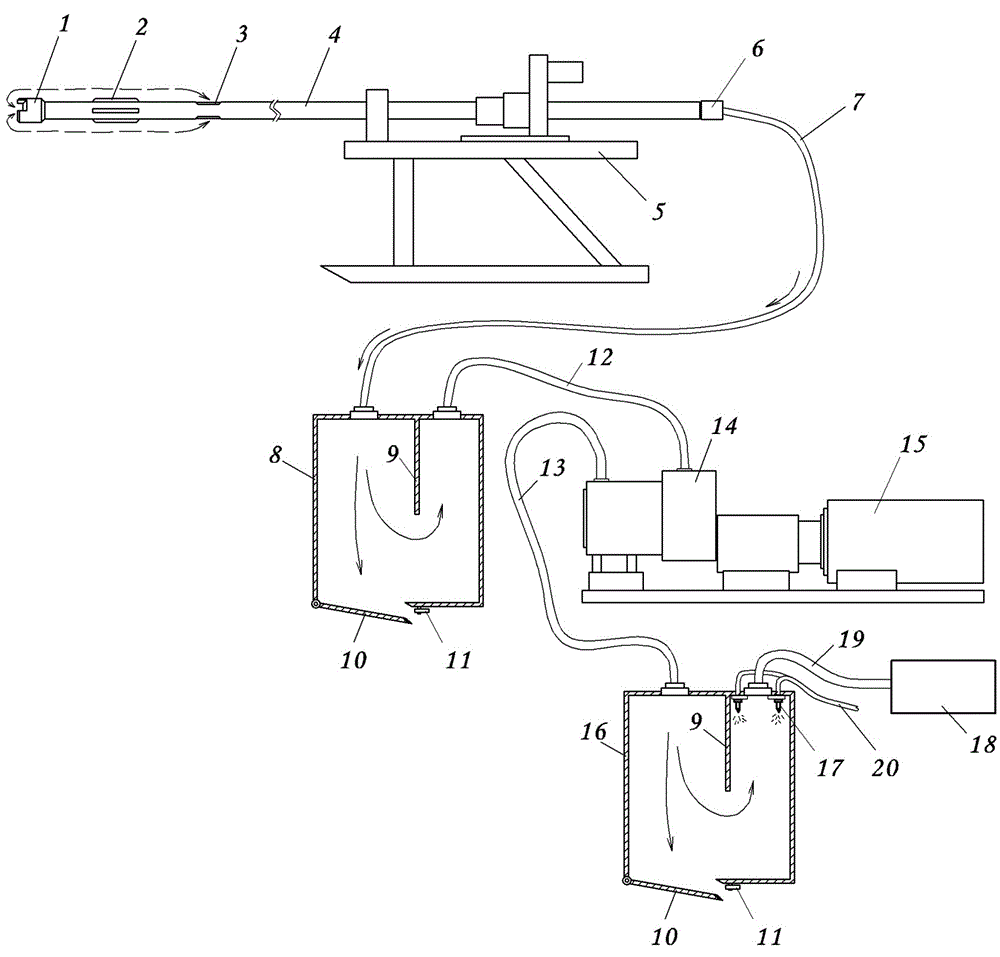

[0014] figure 1 It shows a negative pressure drilling system to prevent gas from exceeding the limit, which is composed of hollow drill rod 4, hollow drill bit 1, hydraulic drilling rig and support 5, exhaust mechanism and drainage system 18 and so on. Wherein, the hollow drill rod 4 is horizontally installed on the support and connected with the hydraulic drilling rig in transmission. The hollow drill bit 1 is installed on the front end of the hollow drill rod 4, and an air extraction port is arranged in the hollow drill bit. At the same time, an air extraction port 3 is arranged on the side wall of the front section of the hollow drill rod 4 (located at the rear side of the hollow drill bit). A section of the hollow drill pipe side wall between the gas ports 3 is evenly provided with a plurality of flaps 2, the flaps 2 are parallel to the axis and have a certain length, and the flaps 2 can also be arranged in a staggered front and rear or in a staggered manner. The wing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com