Torque force protection mechanism

A protection mechanism and torque technology, applied in the direction of electromechanical devices, mechanical equipment, control of mechanical energy, etc., can solve problems such as economic loss, damage to motors or other components, and affect work efficiency, so as to avoid damage to the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

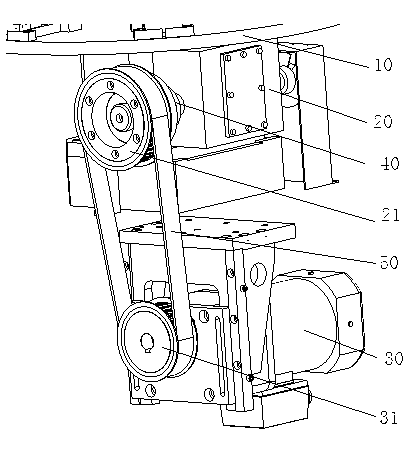

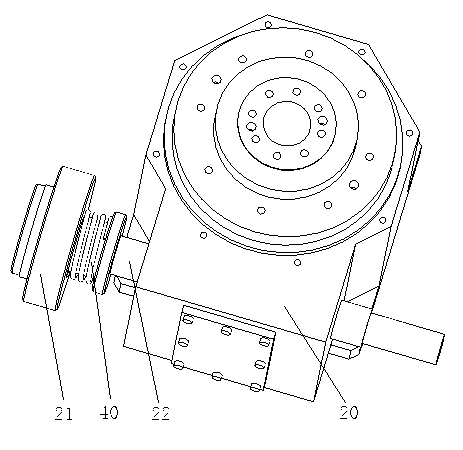

[0012] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0013] Such as figure 1 , figure 2 As shown, the motor housing assembly testing workbench 10 is a disc that can be driven by a driving device to rotate around the center of the circle (only a part is shown in the figure), and 8 stations are set on the workbench 10, and the workbench 10 rotates 45 degrees at a time. The workpiece is transported from the current station to the next station.

[0014] The workbench 10 is driven to rotate automatically by a driving device, and the driving device includes a motor 30 and a worm gear reducer 20 driven by the motor 30 . The output shaft of the speed reducer 20 is connected with the workbench 10 so that the workbench 10 rotates together with the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com