Technology for forming leading wire of touch screen

A touch screen and lead technology, which is applied to the process field of forming touch screen leads, can solve problems such as the inability to meet the requirements of electrostatic shielding, and achieve the effect of improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

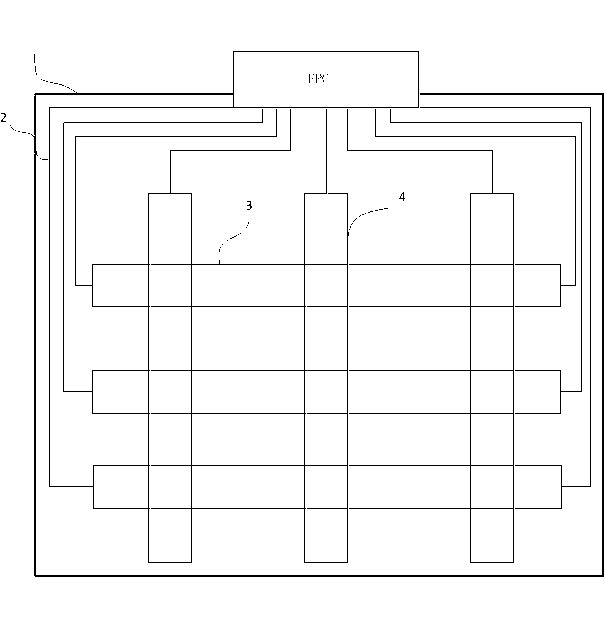

[0029] This embodiment is used to disclose the process of forming touch screen lead wires according to the present invention. The lead wires described in this embodiment include touch electrode signal transmission lines connected to the touch electrodes of the touch screen for connecting the touch electrodes with the touch detection terminals and located on the touch screen. The electrostatic shielding wire (layer) around the electrode signal transmission line, the process of forming the touch screen lead includes the following steps:

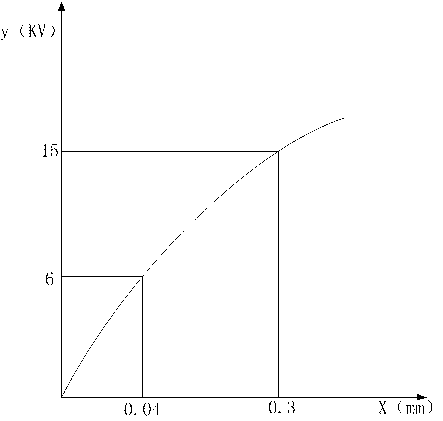

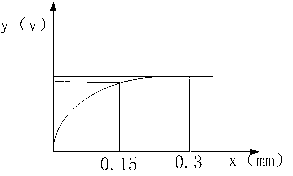

[0030] After the pattern of the touch electrodes is formed, after the pattern of the touch electrodes is formed, the touch electrode signal transmission layer and the electrostatic shielding layer with a distance greater than or equal to 0.3mm are printed, and the electrostatic shielding layer is located on the periphery of the touch electrode signal transmission layer, The touch electrode signal transmission layer is connected with the touch el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com