Water-cooling electric reactor

A water-cooled reactor and reactor technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor cooling, etc., can solve the problem that pipe joints or water separators affect the normal operation of the reactor, and the water-cooled reactor is unstable. and other problems, to achieve the effect of ensuring stable and safe operation, avoiding water seepage, and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

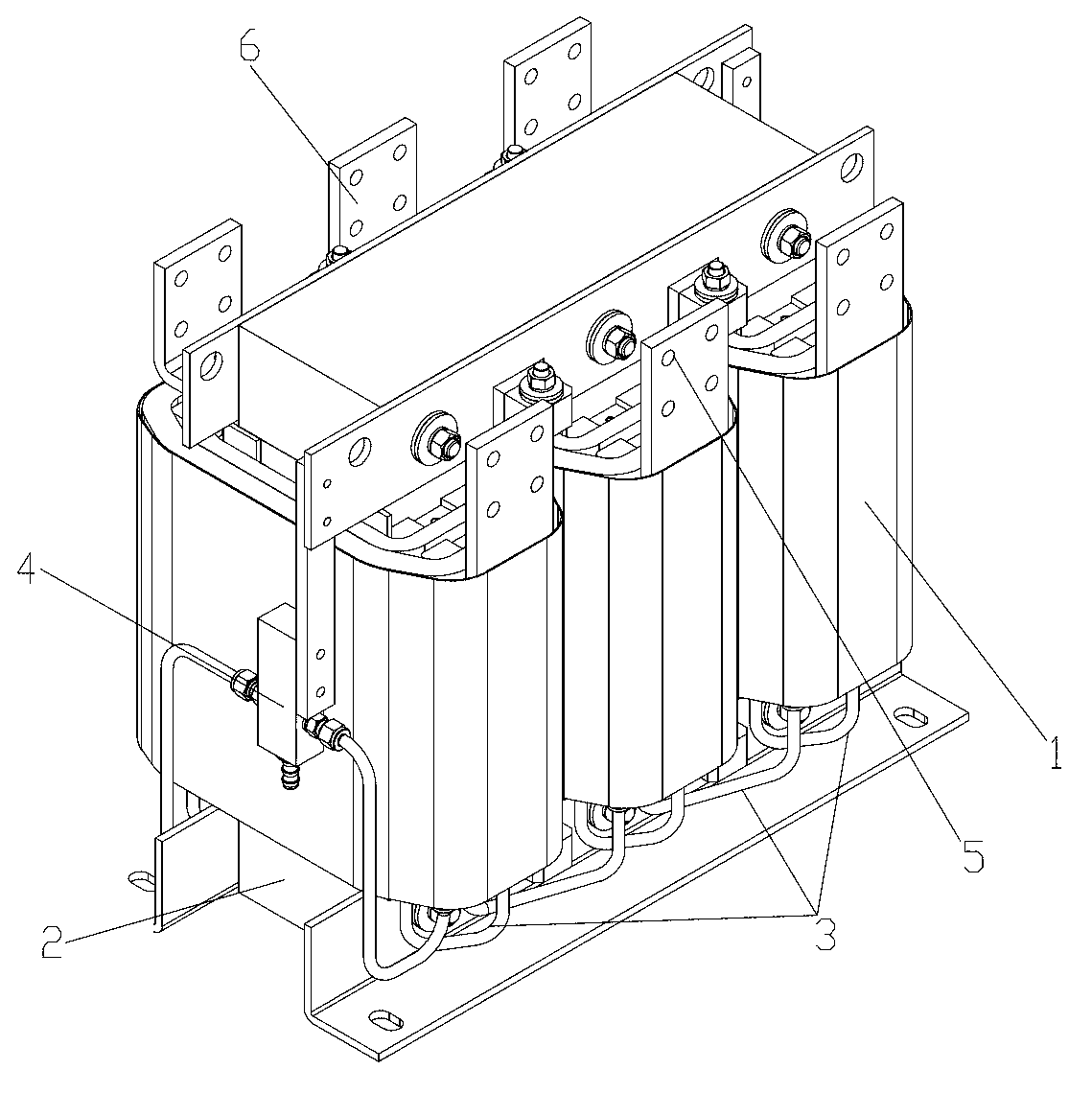

[0014] as attached figure 1 The shown water-cooled reactor according to the present invention includes a winding 1, an iron core 2, a cooling pipeline 3 and a water separator 4, the winding 1 is wound on the iron core 2, and the cooling pipeline 3 Located in the winding 1; the pipe joint of the cooling pipeline 2 is located below the winding 1; the water divider 4 is located at both ends of the reactor; the water divider 4 is provided with two joints; the joints are respectively It is connected with the cooling pipeline 3; the winding 1 is also provided with a coil ending row 5 and a coil starting row 6; the number of the winding 1 is three groups.

[0015] In the water-cooled reactor of the present invention, the pipe joints of the cooling pipeline are below the winding, and the moisture separators are arranged on both sides of the reactor, so that the pipe joints or moisture can be w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com