Three-phase soft-switched PCF rectifiers

一种三相、升压整流的技术,应用在交流功率输入变换为直流功率输出、高效电力电子转换、输出功率的转换装置等方向,能够解决影响电路尺寸、增加成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

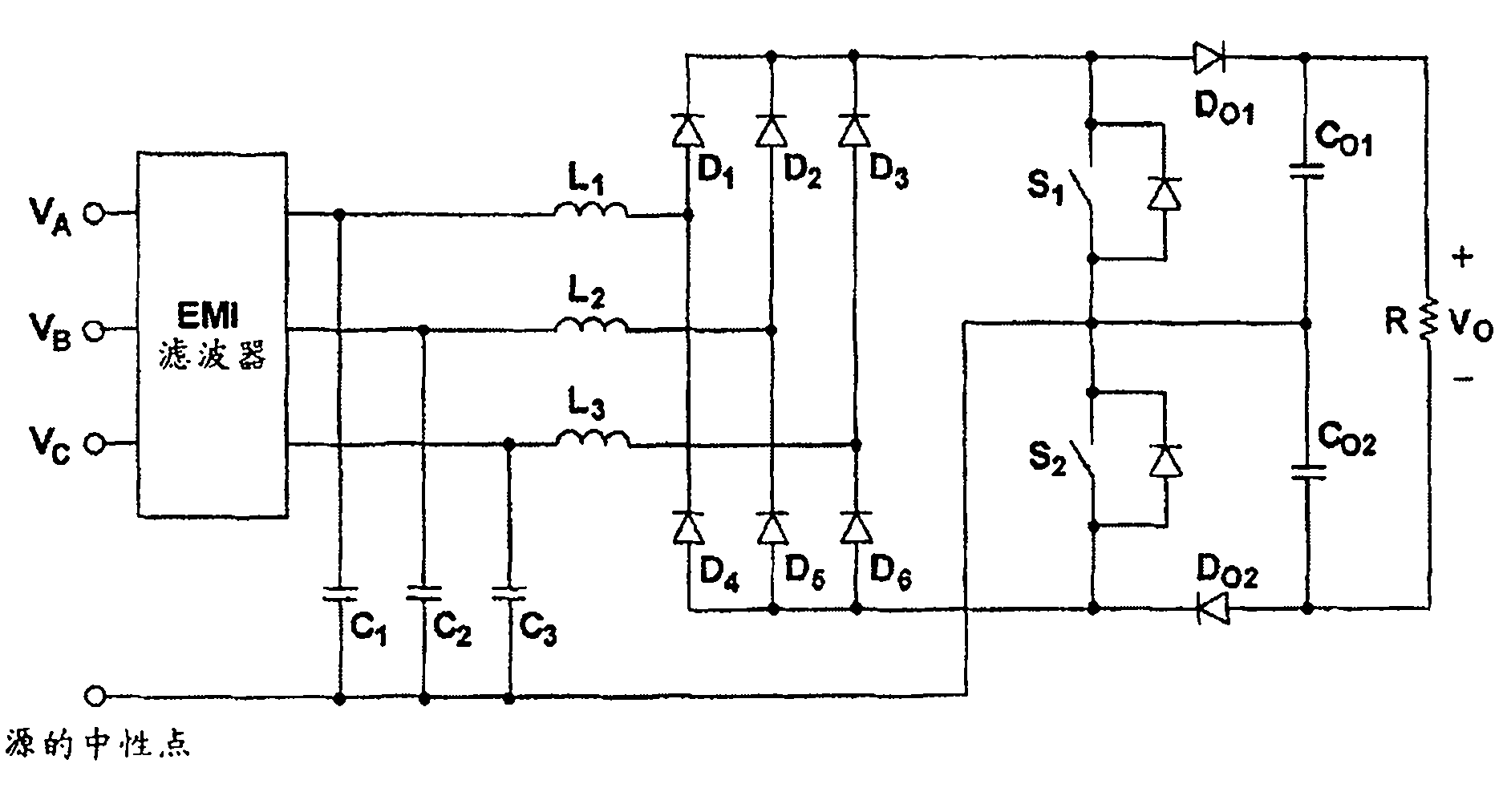

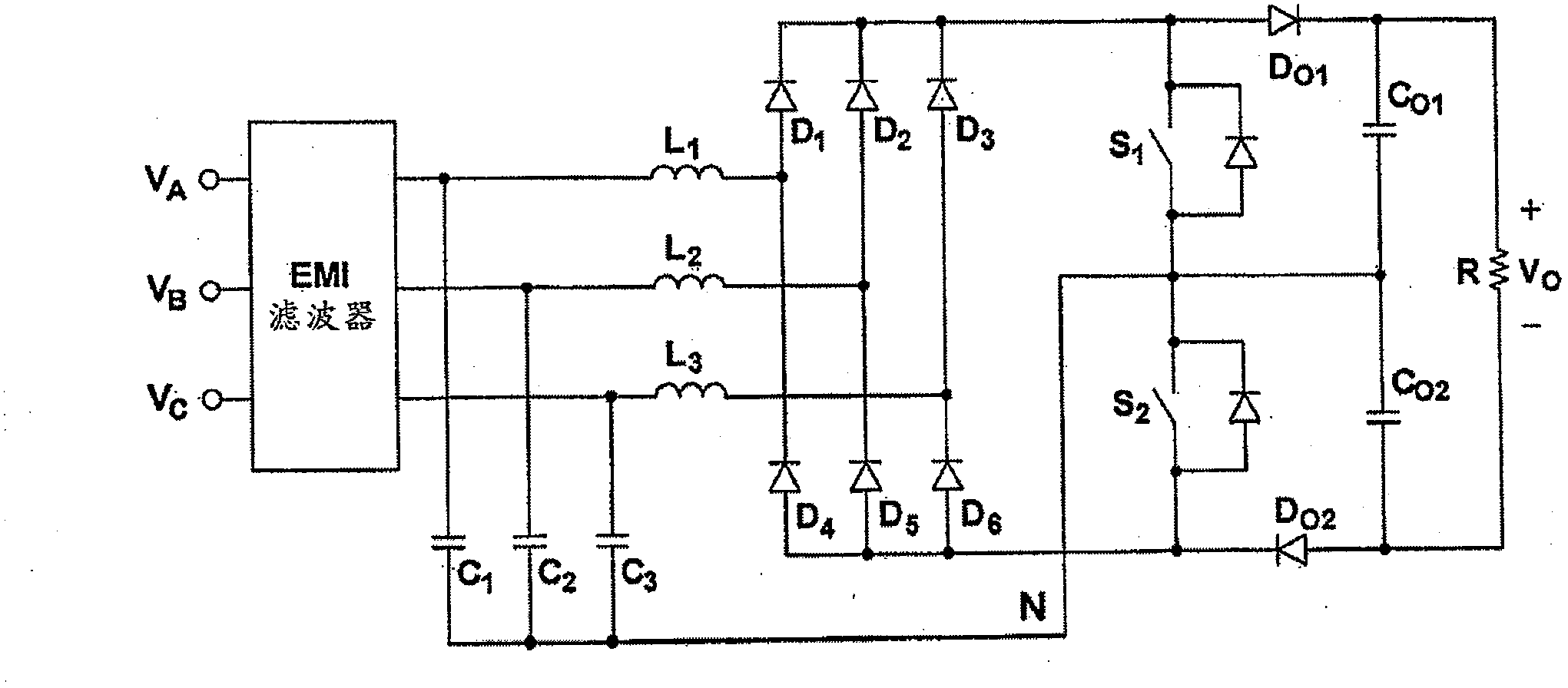

[0073] The present invention relates to a three-phase rectifier implementation that provides low THD and high PF of input current and soft switching of switches over a wide load range. A non-isolated implementation and an isolated implementation are described below. The non-isolated implementation reduces common-mode noise and provides automatic balancing of the split capacitors when using series-connected downconverters. An isolated implementation provides galvanic isolation of the output from the input side. Furthermore, isolated implementations can tightly control their output voltages to minimize unwanted voltage ripple by employing additional phase shifting or pulse width modulation (PWM) control with the added switches. Circuits can also be interleaved to reduce their current and voltage ripple.

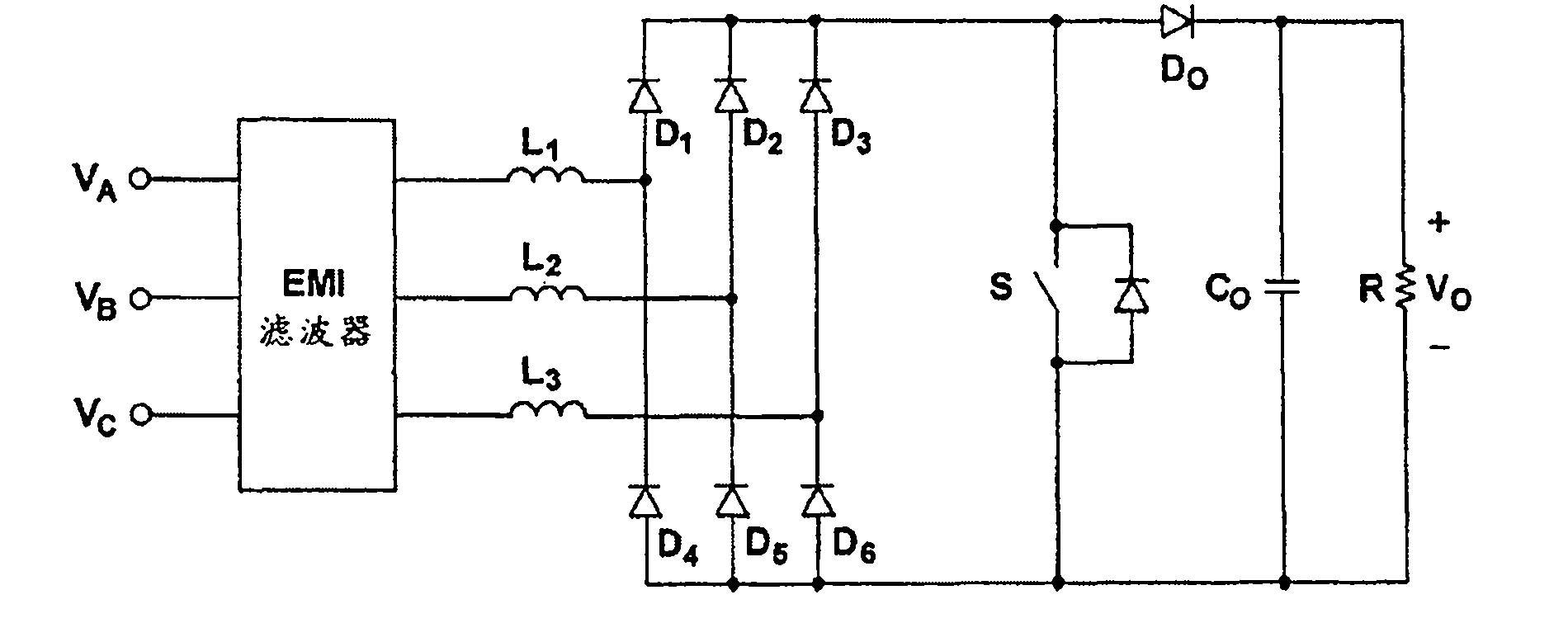

[0074] Figure 6 A block diagram showing a three-phase two-switch ZVS PFC DCM low input current harmonic boost rectifier according to an embodiment of the present invention....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com