Method for interconnecting electronic power modules of a rotary electric machine and assembly of interconnected power modules obtained using said method

A technology for rotating electrical machines and power modules, which is applied in the direction of electric components, electrical components, and the manufacture of motor generators, which can solve the problems of increasing the number of mechanical parts, increasing the complexity, and increasing the cost and price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

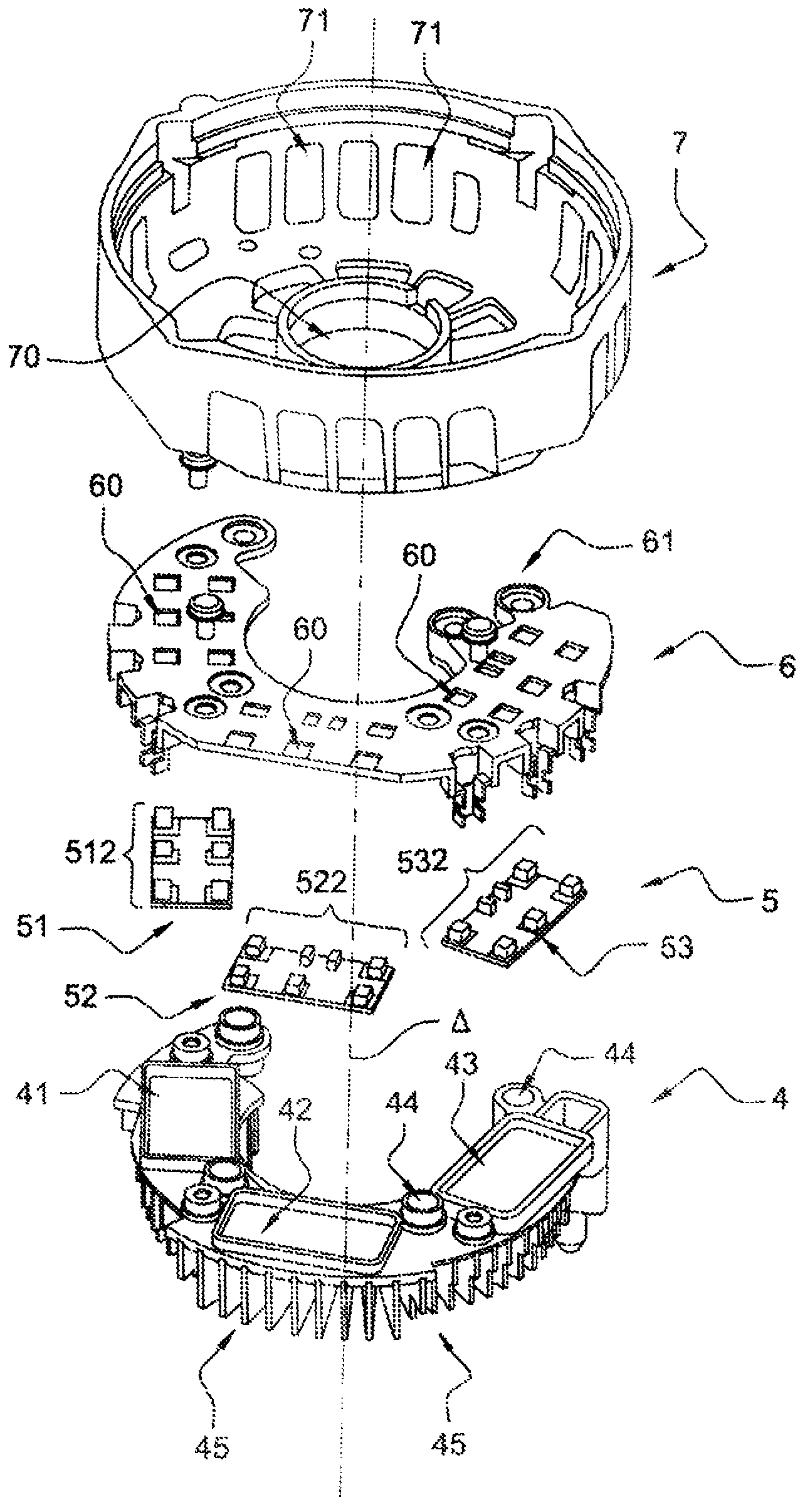

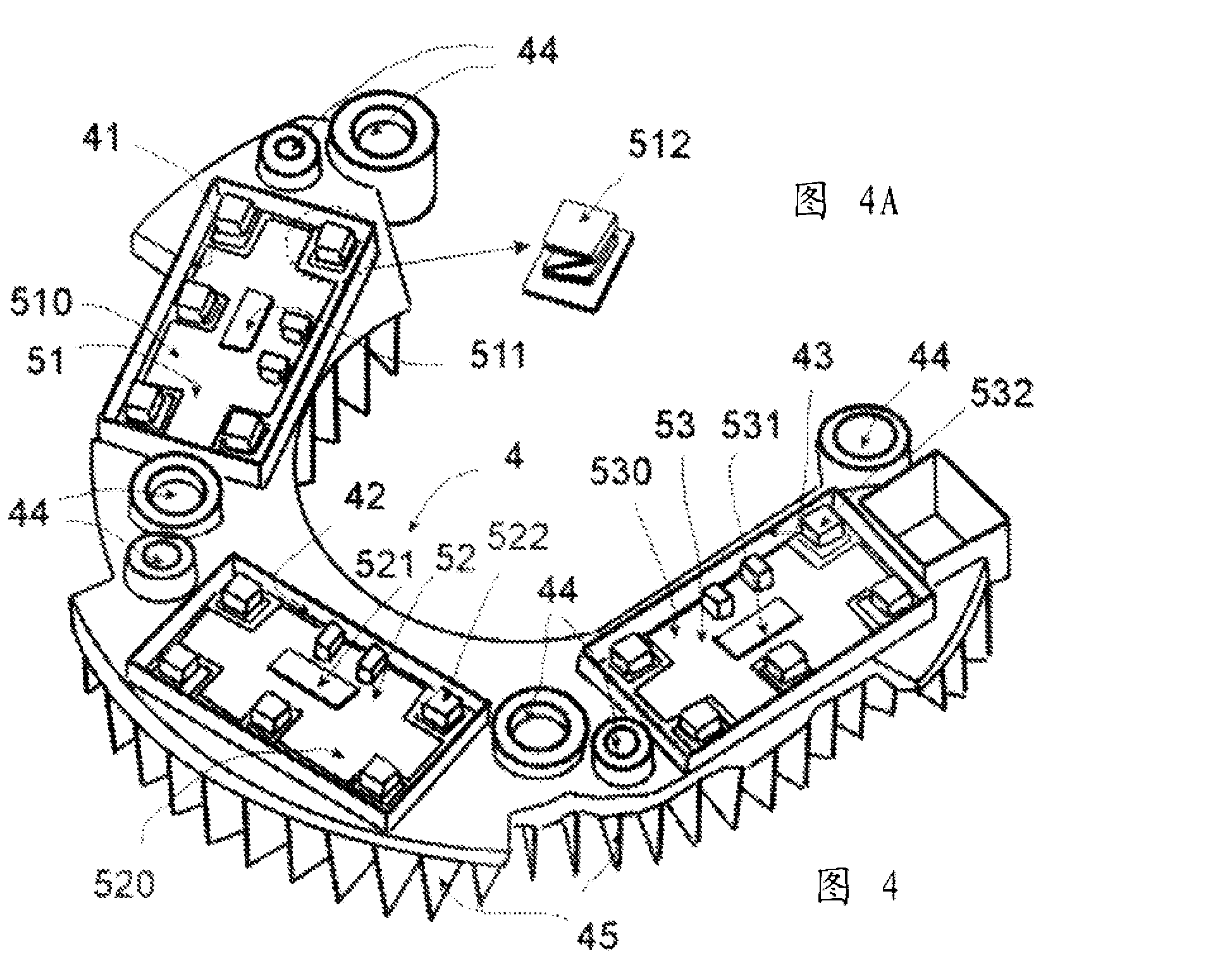

[0036] Hereinafter, without limiting the scope of the invention in any way, the background will be the preferred application of the invention, unless stated otherwise, namely, the case of an alternator with synchronous rectification of the double three-phase type, including three Power modules, each power module comprising the electronic power circuits of the two branches of the rectifier bridge and the control circuits for these electronic power modules.

[0037]Also in the following, identical or at least similar elements in the figures bear the same reference numerals and will only be described again when necessary.

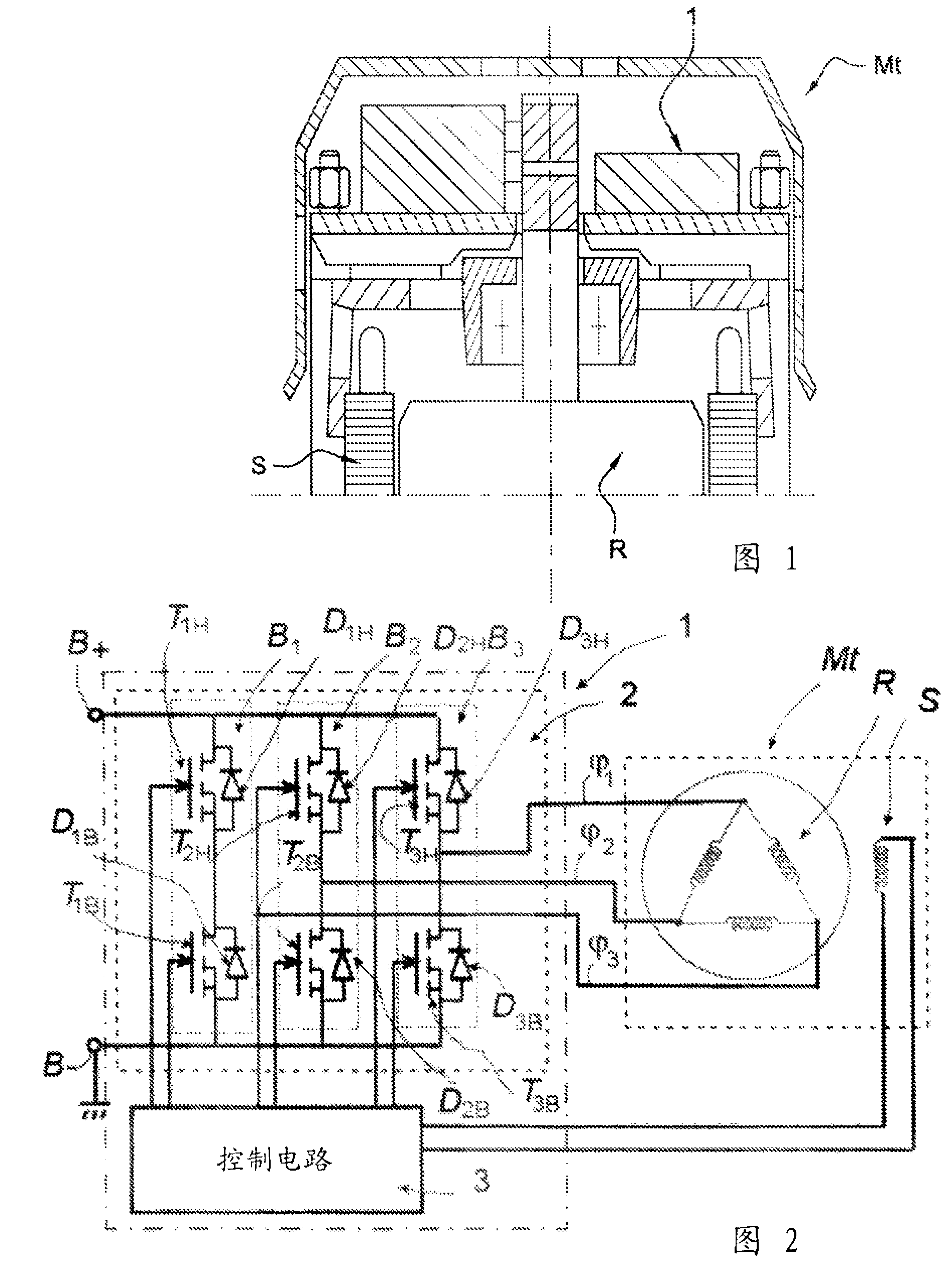

[0038] Before describing the invention, it is advantageous to refer to figure 1 with 2 A brief review of the general structure of this type of motor as well as an example of the electronic power circuits of the bridge rectifier and an example of the electronic circuits used to control these circuits.

[0039] figure 1 An example of the structure of a rota...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap