Road shoulder maintenance machine

A technology for maintaining machines and road shoulders, which is applied in the directions of roads, roads, road repair, etc., can solve the problems of inconvenient lifting mechanism, clumsy work, high labor intensity, etc., and achieve the effect of remarkable work effect, simple overall structure and flexible lifting mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

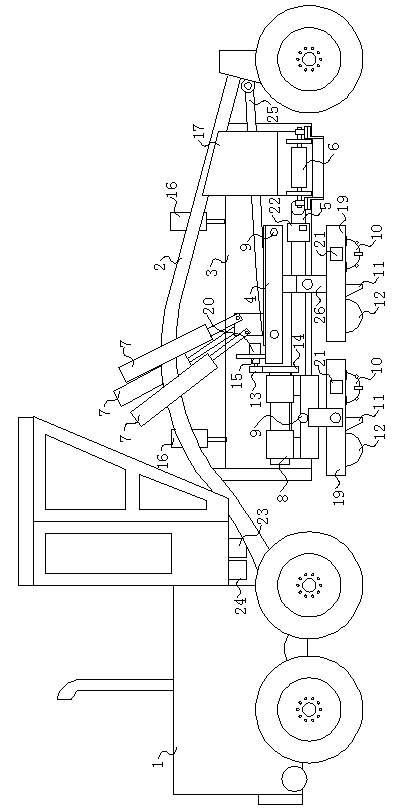

[0012] Attached below figure 1 A kind of road shoulder maintenance machine of invention, make further explanation:

[0013] The road shoulder maintenance machine of the present invention is composed of a locomotive, a vehicle frame, a hopper and a repair mechanism. The rear end of the vehicle frame 2 is fixedly connected to the front end of the locomotive 1, and a hopper 3 and a front part of the hopper 3 are installed on one side of the vehicle frame 2. A discharge port 17 is provided, a longitudinal conveyer belt 5 is arranged at the bottom of the hopper 3, a transverse conveyer belt 6 is arranged at the discharge port 17 at the front end of the longitudinal conveyer belt 5, the road shoulder repair mechanism frame 4 is connected with the vehicle frame 2 through a connecting rod 25, and The road shoulder repair mechanism frame 4 rear side is connected with the roadside slope repair mechanism frame 8. The road shoulder repair mechanism frame 4 and the roadside slope repair m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com