Steel plate and concrete combined underground continuous wall and construction method thereof

A technology of underground diaphragm wall and construction method, applied in sheet pile wall, excavation, foundation structure engineering and other directions, can solve problems such as poor impermeability performance, achieve good impermeability performance, good airtightness, and improve the effect of pouring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

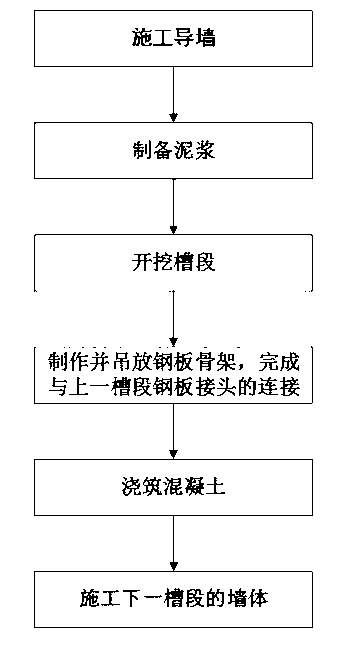

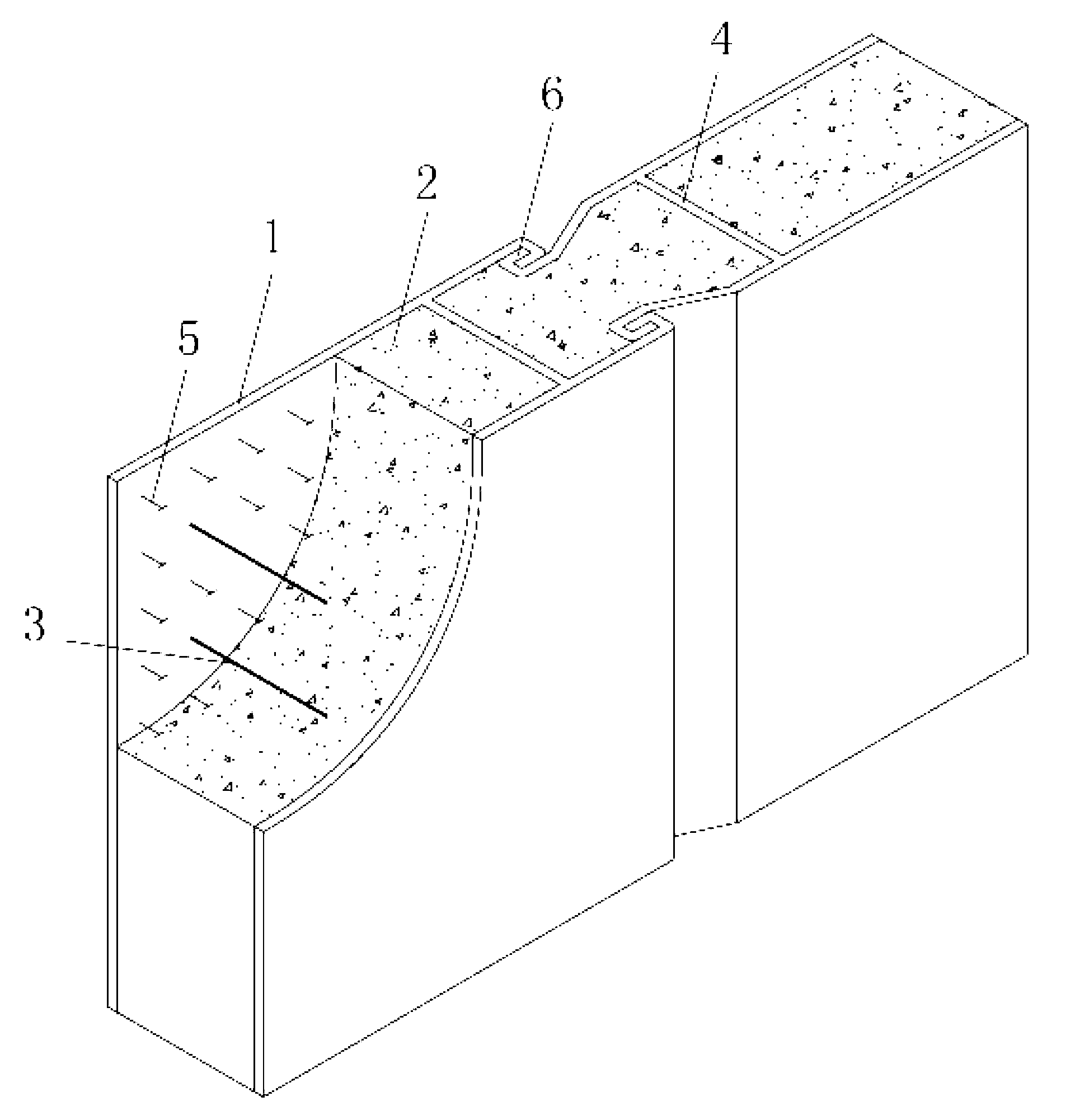

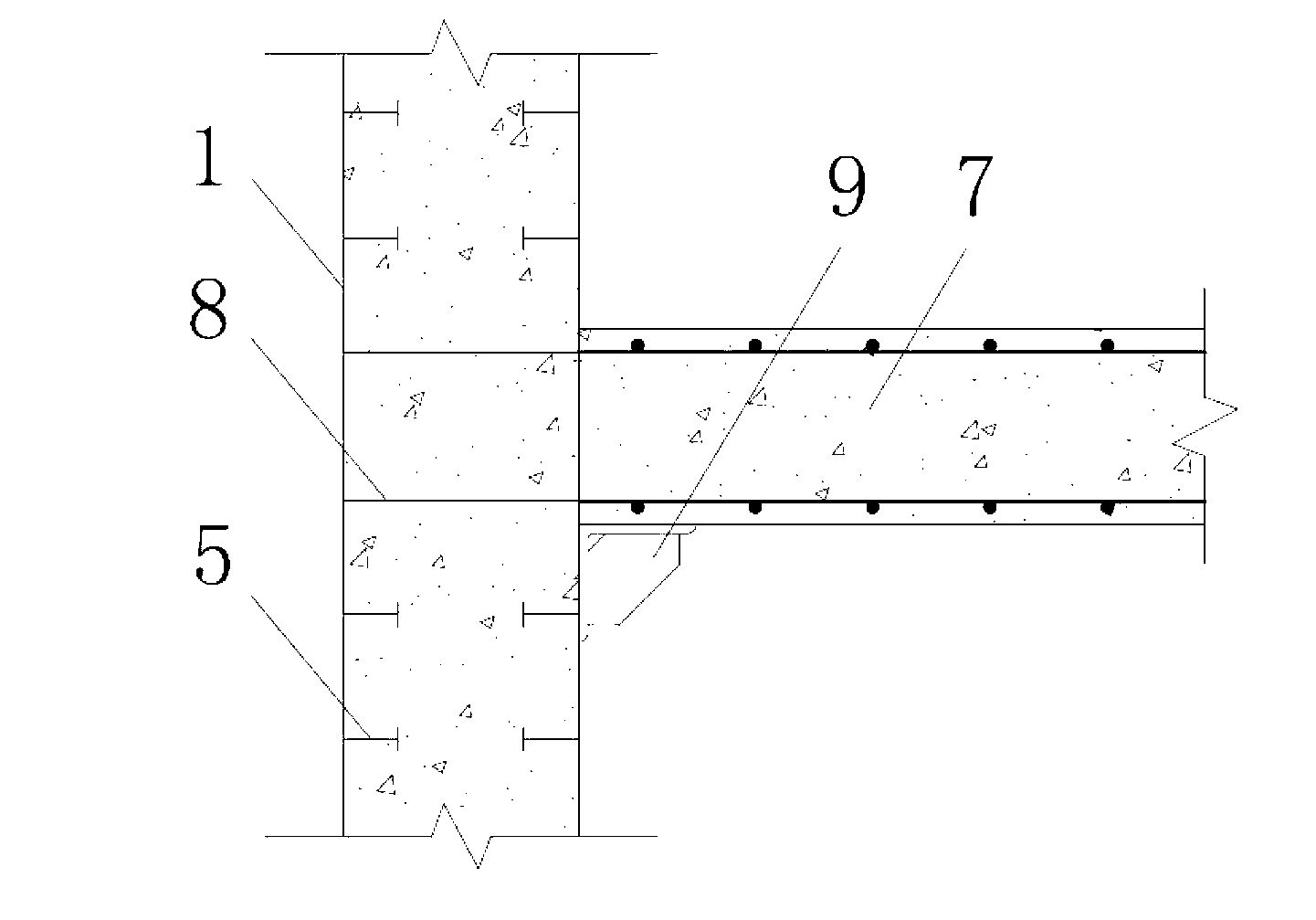

[0037] See figure 1 — Figure 4 , a two-in-one double steel plate concrete composite underground continuous wall, characterized in that the wall is formed by connecting multiple sections of walls, each section of wall is composed of two external steel plates 1 and internal concrete 2, and the external two steel plates 1 It is connected by a cylindrical tension bar 3 and a rectangular vertical partition 4, and the cooperation between the steel plate 1 and the concrete 2 is composed of the tension steel bar 3, the vertical partition 4 and the stud 5 welded on the steel plate 1. Guaranteed, the tensioning steel bar 3 and the vertical partition 4 also play the role of maintaining a certain rigidity and bearing the out-of-plane load during transportation. In addition, due to the existence of the vertical partition 4, the concrete can be poured in separate bins, eliminating the need for joint pipes. The steel plate 1 is bent into an L shape at the end to form a steel plate joint 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com