Filling material guiding mechanism of solid filling conveying machine

A technology of solid filling and conveying machine, which is applied to filling materials, safety devices, mining equipment, etc., can solve the problems that the compaction mechanism is difficult to compact quickly, affects the efficiency of coal mining, and prolongs the mining time, so as to improve the efficiency of filling work, Improve the filling effect and increase the effect of stacking space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

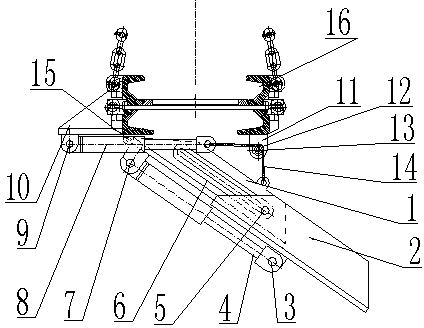

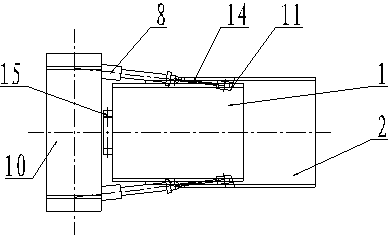

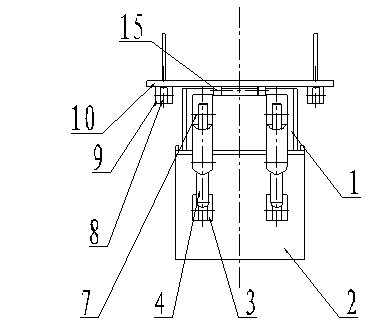

[0015] Such as figure 1 As shown, the filling guide mechanism of the solid filling conveyor of the present invention is mainly composed of an inner tank 1, an outer tank 2, an inclined hydraulic jack 4, a horizontal hydraulic jack 8, a fixed steel plate 10, and a pulley 12. The fixed steel plate 10 is designed On the outer side of the lower side of the discharge port of the filling conveyor 16, the pulley 12 is arranged on the side of the inner side of the filling coal mining conveyor 16, and the pulley 12 is fixed on the front connecting seat 11 through the pulley pin shaft 13. The horizontal hydraulic pressure Jack 8 is located on the bottom of fixed steel plate 10 through horizontal hydraulic jack fixed pin 9, and the horizontal hydraulic jack 8 that steel plate 10 bottoms is provided with is two, symmetrically arranged. Below the horizontal hydraulic j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com