Self calibration method for image measuring instrument

An image measuring instrument and self-calibration technology, which is applied to measuring devices, instruments, and optical devices, etc., can solve the problems of cumbersome operation process, pollution and wear of calibration plate, and high price, and achieve simple operation, rapid calibration, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

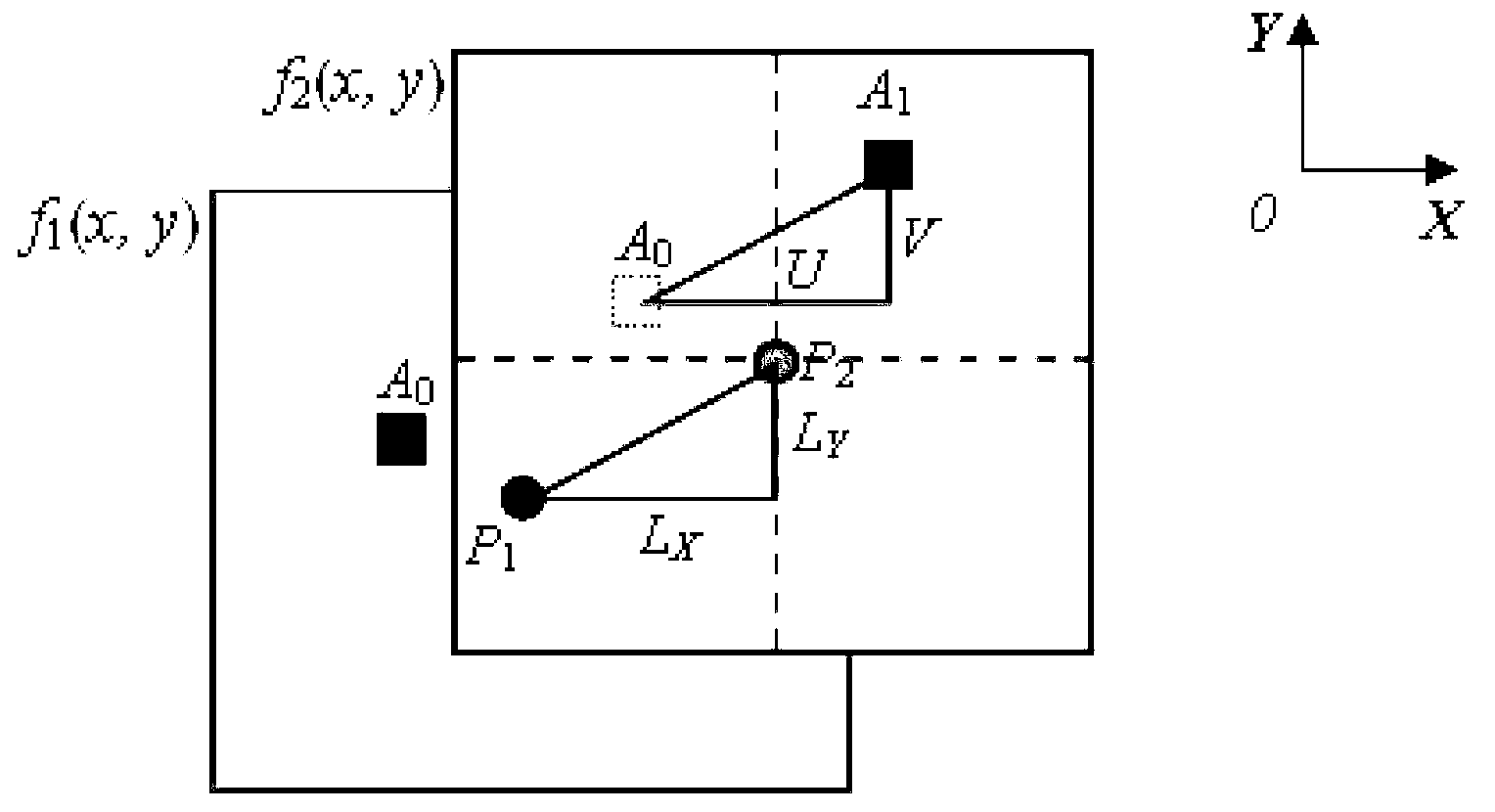

[0018] The self-calibration method for the image measuring instrument of this patent will be further described in detail below with reference to the accompanying drawings.

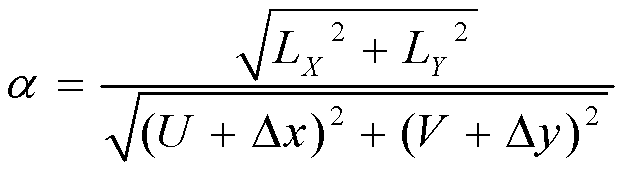

[0019] Such as figure 1 shown. When measuring, the workpiece is placed on the glass table of the image measuring instrument, and the measuring instrument will display and collect sample images through its microscopic imaging system. This embodiment is based on the principle of mathematical image correlation, and takes two adjacent images of the measured workpiece before and after translation in the two-dimensional plane as the object, calculates the pixel displacement value, and then combines the reading value of the grating ruler when the image is collected to obtain the actual physical Finally, according to the ratio of the two, the scale factor α of the image measuring instrument is obtained to realize the self-calibration of the image measuring instrument.

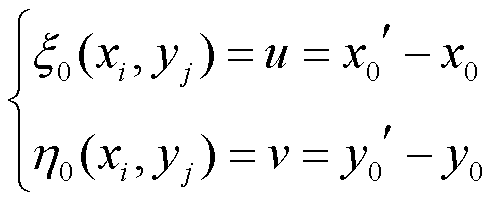

[0020] In this embodiment, the sample imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com