Water pressure testing machine tube length infinitely adaptable to the rotary device

A technology of hydraulic testing machine and tube length, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of high cost, damage to sealing rings, slow speed, etc., and achieve the effects of easy control, convenient maintenance, and safe and reliable equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

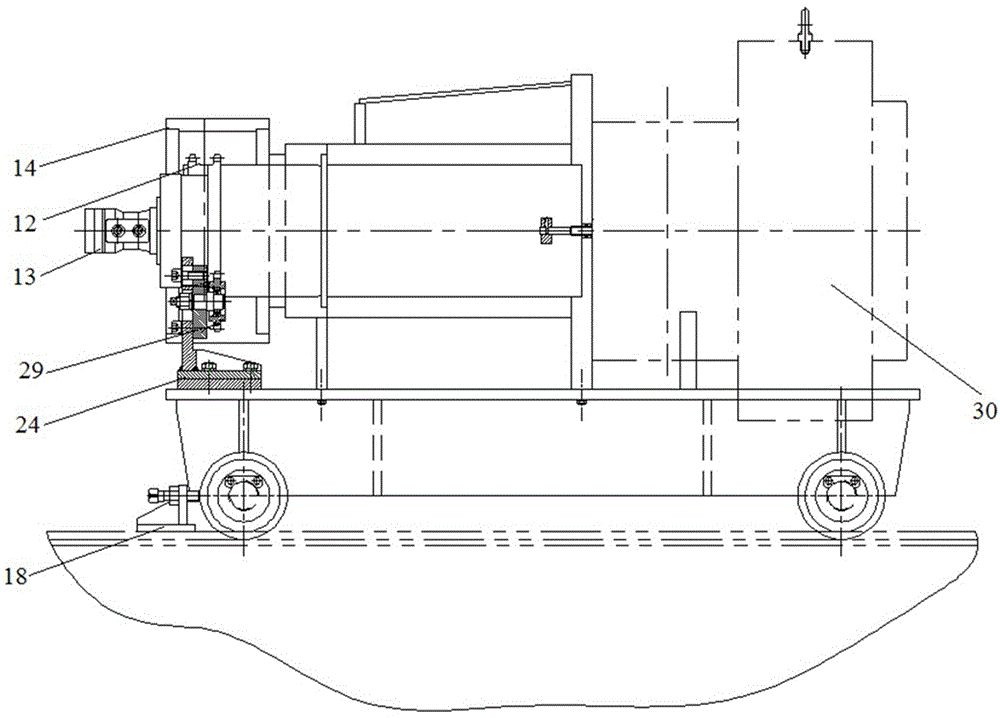

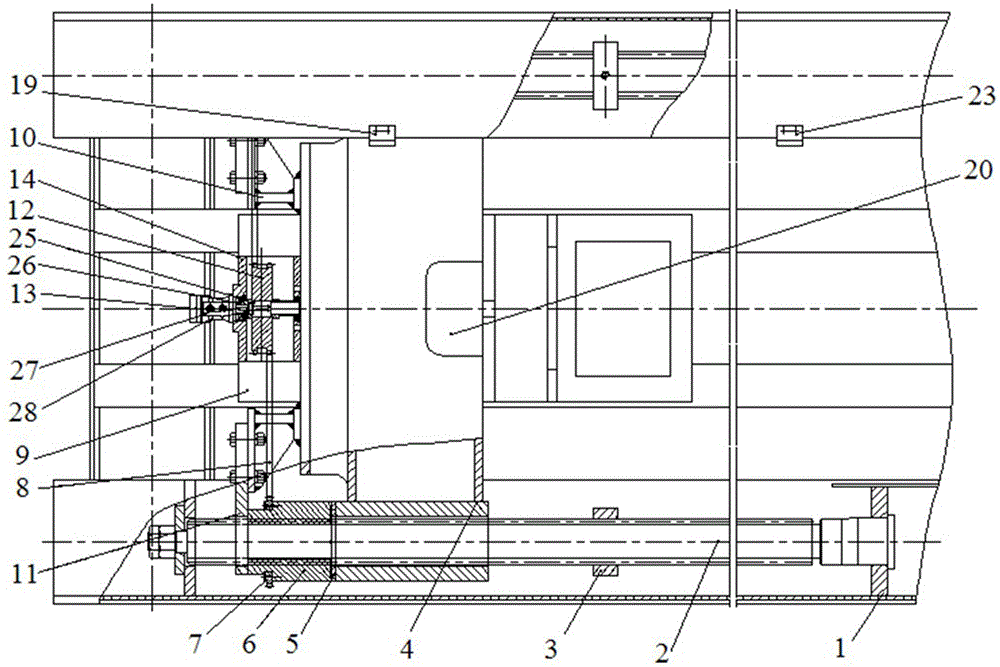

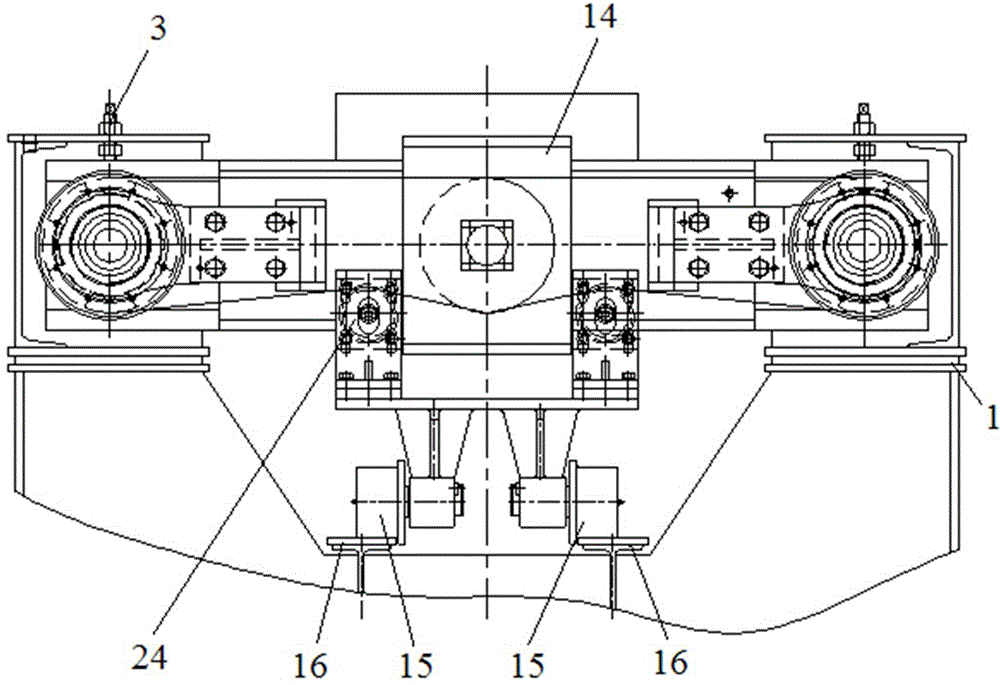

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] Such as figure 1 , figure 2 and image 3 As shown, the infinitely adaptable rotary device of the present invention comprises a walking trolley 9, which is placed on two guide rails 16, and the wheels 15 of the walking trolley 9 are in contact with the guide rails 16, and the walking trolley 9 can reciprocate along the guide rails 16. The root guide rail 16 is fixedly connected with a mechanical limiter 18 respectively, and the position of the mechanical limiter 18 is the final limit position that the walking trolley 9 can reach; the walking trolley 9 is equipped with a structure such as Figure 4 The carrier frame 4 shown, the carrier frame 4 comprises a "convex" shaped frame body 31, a carrier plate 32 is provided on the end face of the larger end of the frame body 31, and a carrier sleeve 21 is provided on both sides of the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com